Specifications

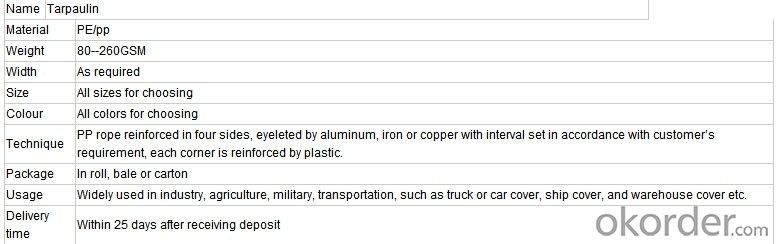

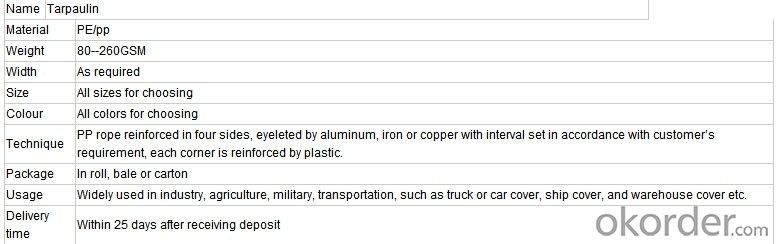

The Material is polypropylene. Widely used in industry, agriculture, transportation, such as truck or car cover.Our company produces pe/pp pvc tarpaulin,color\specification is complete,Production according to customer requirements

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: 100% Polyester Supply Type: Make-to-Order Type: Tarpaulin Pattern: Coated Coated Type: HDPE Laminated Width: Other Technics: Woven Feature: Waterproof, Anti-Static, Tear-Resistant, Blackout, Shrink-Resistant Use: Awning, Car, Bag, Military, Tent, Umbrella, Industry, Wedding Yarn Count: 8*8,10*10,12*12,14*14,etc. Weight: 100-260gsm Density: 9*9,10*10,12*12,4*14,16*16 Model Number: Multiple color: orange/blue /green size: various sizes . Our company produces pe/pp pvc tarpaulin,color\specification is complete,Production according to customer requirements Quick Details

Packaging & Delivery

Packaging Details: packed in bale(20-40kg) or carton or roll Delivery Detail: within 25 days after receiving prepayment Specifications

The Material is polypropylene. Widely used in industry, agriculture, transportation, such as truck or car cover.

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords