0.5% Mositure and 85%FC coke for foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.3

- Supply Capability:

- 1003 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

Foundry Coke is the main fuel of melting iron in the oven. It can melt the materials in the over, make the iron reach great heat, and keep good air permeability by sustain stock column. Thus, the foundry coke should have the characteristics of big block, low reactivity, small porocity, enough anti-crush strengh, low ash and low sulphur.

The coke handled by our cooperation is made from superior coking coal of Shanxi province. Provided with the advantages of low ash, low sulphur and high carbon. Our coke is well sold in European, American, Japanese and South-east Asian markets. Our owned Coke plant are located in Shanxi Province and supplying of you many kinds of coke.

we supply Foundry Coke long-term, its characteristic is best strength, low sulfur and phosphorus,thermal stability.it is more and more wildely-used

Specifications:

ASH % | 8% max | 10% max | 12% max |

V.M.% MAX | 1.5% max | 1.5% max | 2% max |

SULFUR % | 0.65% max | 0.65% max | 0.7% max |

MOISTURE | 5% max | 5% max | 5% max |

Size | 80mm-120mm,80-150,100-150mm, or as request | ||

Features

1. Our quality is always quite good and stable which is producing and packing according to customers' requirements.

2. Putting Client profile into first, achieved mutual benefit.

3. Good partner on business. It's a good and wise choice for customers' to purchase from us. It's our great honor to cooperate with you.

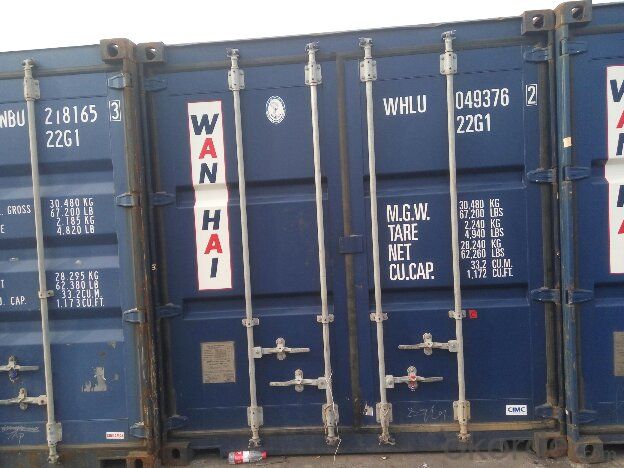

4. We can supply documents as follows:

- bill of loading,

-Invoice,

-Packing List

-Insurance

-standard inspection pictures of the container as specified by INSPECTORATE

-or more requested by buyer.

Pictures

FAQ

1. What is the packing?

In 25kg bag/ In jumbo bags without pallet/ Two jumbo bags with one pallet/ or as customers’ request

2. What is the production capacity?

10 thousand tons per month

3 What is payment term?

Irrevocable LC at sight/ 20% down payment by T/T and 80% against BL copy byT/T/ or to be discussed

4 What is the service?

We will send sample to the third party(CIQ, CCIC, SGS,BV or to be discussed) for checking, and present the test certificate and loading repot of shipment.

- Q: What is fullerene?

- Fullerene refers to a molecule made entirely of carbon atoms, arranged in a unique structure resembling a hollow cage or sphere. It is a form of allotrope of carbon, alongside graphite and diamond. The most common and well-known fullerene is called buckminsterfullerene, or simply C60, which consists of 60 carbon atoms arranged in a soccer ball-like shape. Fullerenes can also vary in size, ranging from as few as 20 carbon atoms to several hundred. They can be found naturally in soot and formed through various methods, such as laser ablation or chemical vapor deposition. Due to their distinctive structure, fullerenes possess remarkable properties, including high strength, low density, and excellent electrical and thermal conductivity. They have found applications in various fields, including nanotechnology, electronics, medicine, and materials science.

- Q: What are the impacts of carbon emissions on the spread of infectious diseases?

- The impacts of carbon emissions on the spread of infectious diseases are significant. Carbon emissions contribute to climate change, which in turn affects various factors that influence the spread of diseases. Rising temperatures, changes in precipitation patterns, and altered ecosystems all play a role in creating favorable conditions for the proliferation and transmission of infectious diseases. These changes can lead to the expansion of disease vectors like mosquitoes, ticks, and rodents, and increase the geographical range of diseases such as malaria, dengue fever, and Lyme disease. Additionally, carbon emissions can weaken human immune systems and exacerbate respiratory illnesses, making individuals more susceptible to infections. Overall, reducing carbon emissions is crucial to mitigate the impacts of climate change and curb the spread of infectious diseases.

- Q: How is carbon used in the production of steel?

- Carbon is a crucial element in the production of steel as it directly affects the properties and characteristics of the final product. In the steelmaking process, carbon is primarily used as an alloying element, which means it is added in controlled amounts to modify the steel's composition. One of the most common methods of steel production is through the basic oxygen furnace (BOF) process. In this process, carbon is added to the molten iron to create the desired steel grade. The amount of carbon added determines the steel's hardness, strength, and other mechanical properties. Generally, higher carbon content results in harder and stronger steel. Carbon is also used in another steelmaking process called the electric arc furnace (EAF) process. Here, recycled steel scrap is melted down using an electric arc to produce new steel. Carbon is added during this process to adjust the carbon content as required for the desired steel grade. Furthermore, carbon plays a crucial role in the heat treatment of steel. Through processes like carburizing and quenching, carbon is used to enhance the surface hardness and wear resistance of steel components. This is particularly important in industries such as automotive, aerospace, and construction, where the durability and strength of steel are paramount. In summary, carbon is essential in the production of steel as it directly influences the mechanical properties and overall quality of the final product. From adjusting the carbon content to controlling the heat treatment processes, carbon is a vital component in the steelmaking industry.

- Q: How are carbon nanotubes used in various applications?

- Carbon nanotubes are used in various applications due to their unique properties. They are used in electronics and semiconductors for their high conductivity, in energy storage devices for their high surface area and lightweight nature, and in medicine for drug delivery and imaging purposes. Additionally, carbon nanotubes find applications in materials science, aerospace engineering, and environmental remediation, among others, showcasing their versatility and potential impact across multiple fields.

- Q: What are the impacts of carbon emissions on water scarcity?

- Water scarcity is significantly impacted by carbon emissions. One way in which carbon emissions contribute to water scarcity is through climate change. The presence of increased carbon dioxide in the atmosphere causes heat to become trapped, resulting in global warming and changes in weather patterns. These altered climate patterns can lead to changes in rainfall, including more frequent droughts and decreased rainfall in certain areas. The consequences of droughts can be particularly severe for water availability. When there is a lack of rainfall, rivers, lakes, and reservoirs can dry up, leaving communities without access to fresh water sources. This scarcity of water affects drinking water, agriculture, and industrial use, impacting both human populations and ecosystems. Moreover, carbon emissions also affect water scarcity by impacting the melting of glaciers and snowpack in mountainous regions. These areas serve as natural water reservoirs, releasing water slowly throughout the year and providing a reliable source of freshwater downstream. However, as temperatures rise due to carbon emissions, glaciers and snowpack melt at a faster rate. This leads to increased water runoff, resulting in flooding and a decrease in water availability during dry seasons. Carbon emissions also indirectly contribute to water scarcity through their influence on sea-level rise. The increased temperatures caused by carbon emissions cause polar ice caps to melt, which in turn raises sea levels. Consequently, saltwater infiltrates coastal aquifers, making the groundwater brackish or undrinkable. This intrusion contaminates freshwater sources, reducing their availability and exacerbating water scarcity. Additionally, carbon emissions contribute to ocean acidification, which harms marine ecosystems. This, in turn, affects the availability of seafood resources, which are an essential source of protein for many people worldwide. The decline in seafood availability puts additional pressure on freshwater resources as it may lead to increased reliance on agriculture, which requires substantial amounts of water. To summarize, carbon emissions have significant impacts on water scarcity. Climate change resulting from carbon emissions alters precipitation patterns, leading to droughts and reduced rainfall. Carbon emissions also accelerate the melting of glaciers and snowpack, reducing water availability in mountainous regions. Furthermore, carbon emissions contribute to sea-level rise, resulting in saltwater intrusion into freshwater sources. These impacts emphasize the urgent need to reduce carbon emissions and mitigate the effects of climate change to ensure the availability of freshwater resources for present and future generations.

- Q: What is carbon sequestration?

- Carbon sequestration is the process by which carbon dioxide (CO2) is captured from the atmosphere and stored for an extended period of time, preventing it from being released and contributing to climate change. This technique aims to reduce the concentration of CO2 in the atmosphere, as this greenhouse gas is a major driver of global warming. Carbon sequestration can occur naturally through biological processes, such as photosynthesis in plants and algae, or it can be achieved through various artificial methods. Natural carbon sequestration occurs when plants, trees, and other vegetation absorb CO2 during photosynthesis and store it in their tissues. This process, known as terrestrial sequestration, plays a crucial role in reducing atmospheric CO2 levels. Additionally, oceans also act as a significant sink for CO2, absorbing and storing vast amounts of it. This is referred to as oceanic sequestration. Artificial carbon sequestration techniques involve capturing CO2 emissions from industrial processes, power plants, and other sources before they are released into the atmosphere. There are several methods for carbon capture, including pre-combustion capture, post-combustion capture, and oxy-fuel combustion. Once the CO2 is captured, it can be transported and stored underground in geological formations, such as depleted oil and gas fields or saline aquifers. This process is commonly known as carbon capture and storage (CCS) or carbon capture utilization and storage (CCUS). Carbon sequestration has gained significant attention due to its potential to mitigate climate change. By reducing the amount of CO2 in the atmosphere, it helps to slow down the pace of global warming and reduce the impacts of climate change. It is considered to be a crucial part of the broader strategy to achieve net-zero emissions, as it not only reduces future emissions but also removes CO2 that has already been emitted. However, carbon sequestration is not a silver bullet solution to climate change. It should be seen as a complementary approach to other mitigation efforts, such as transitioning to renewable energy sources and improving energy efficiency. Additionally, the long-term storage of CO2 requires careful monitoring and management to ensure its effectiveness and prevent any leakage or environmental risks. Overall, carbon sequestration is a vital tool in the fight against climate change, offering the potential to reduce greenhouse gas emissions and contribute to a more sustainable future.

- Q: What is the relationship between carbon emissions and deforestation?

- The relationship between carbon emissions and deforestation is closely intertwined. Deforestation refers to the permanent removal of trees and vegetation in forests, usually to make way for agricultural land, urban development, or logging. This process releases large amounts of carbon dioxide (CO2) into the atmosphere, contributing to greenhouse gas emissions and climate change. Trees play a crucial role in mitigating climate change as they absorb CO2 from the atmosphere through photosynthesis and store it in their tissues. When forests are cleared, this carbon storage capacity is lost, and the carbon previously stored in trees is released back into the atmosphere. Deforestation is estimated to be responsible for around 10% of global greenhouse gas emissions. Furthermore, the burning of forests, a common practice during deforestation, also contributes to carbon emissions. When trees are burned, the stored carbon is released as CO2, exacerbating the greenhouse effect. This is particularly significant in tropical regions where deforestation is prevalent, such as the Amazon rainforest. Conversely, reducing deforestation and promoting reforestation can help mitigate carbon emissions. By preserving existing forests and planting new trees, we can enhance carbon sequestration and reduce the amount of CO2 in the atmosphere. Forest conservation and restoration efforts are crucial components of global climate change strategies, as they not only help combat climate change but also preserve biodiversity and provide vital ecosystem services. In conclusion, the relationship between carbon emissions and deforestation is clear: deforestation leads to increased carbon emissions, while forest conservation and reforestation efforts help reduce carbon dioxide levels in the atmosphere. It is essential to prioritize sustainable land-use practices and support initiatives that protect and restore forests to mitigate climate change effectively.

- Q: Carbon injection molding machine heating several degrees

- The quick test method for judging drying effect is to use the "air injection" on the injection molding machine". If the material flowing slowly from the nozzle is uniform and transparent, light silver strips and bubbles, is qualified. This method applies to all plastics.The melt viscosity of PC is much larger than that of PA, PS, PE, and the flowability is poor. Melt flow properties close to Newtonian fluid. The viscosity of the melt shear rate had little effect, and is very sensitive to changes in temperature, therefore, only by adjusting the molding processing temperature, viscosity can effectively control PC.The selection of molding temperature is relative to the average molecular weight of the resin and its distribution, the shape and size of the product, the type of the injection molding machine, and so on. It is generally controlled in the range of 250~310 centigrade. For injection molding, the resin with relatively low average molecular weight should be selected, MFR is 5 to 7g/10min; complex shape or thin wall products. Molding temperature should be high, 285~305 degrees; and thick wall products, molding temperature is slightly lower, to 250~280 degrees. Different injection molding machine, molding temperature is not the same. The screw type is 260~285 degrees, and the plunger type is 270~310 degrees centigrade. The setting of the material temperature is in the form of front high and low, near the end of the hopper, the temperature of the barrel should be controlled above the softening temperature of PC, that is greater than 230 degrees, to reduce the material resistance and injection pressure loss. In spite of increasing molding temperature, melt filling is beneficial. But not more than 230 DEG C, otherwise PC will degrade, make the products become darker in color, appear on the surface of silver, dark, black spots, bubbles and other defects, at the same time, the physical and mechanical properties will be significantly decreased.

- Q: What type of carbon copy sheet can be printed on? How many copies?

- Printed in carbon free carbon paper, usuallyUpper: whiteMedium: RedNext: yellowMainly depends on how much you want to print.

Send your message to us

0.5% Mositure and 85%FC coke for foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.3

- Supply Capability:

- 1003 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches