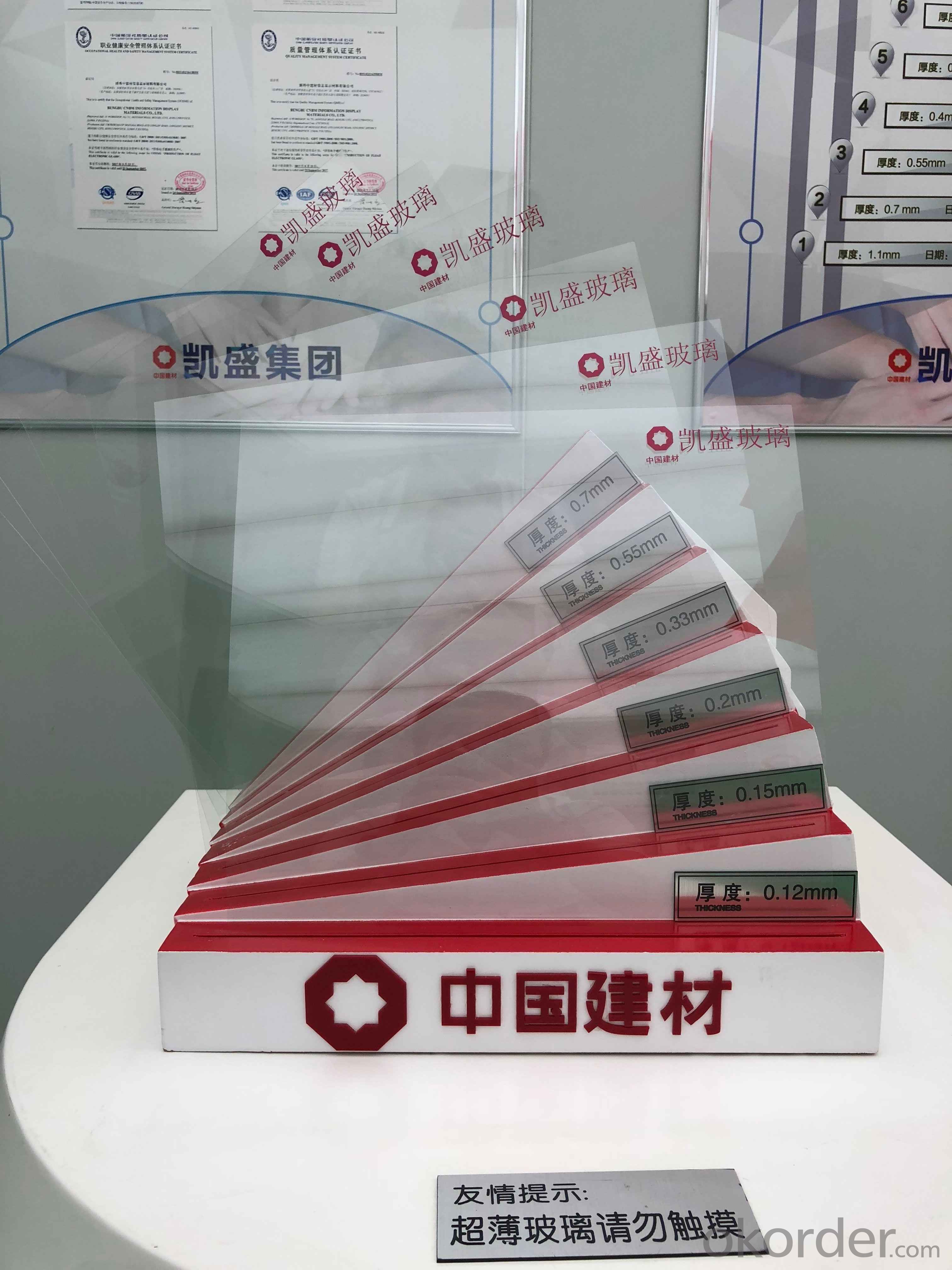

0.33 mm medium aluminum ultrathin electronic glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1291 m²

- Supply Capability:

- 129100 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

0.33 mm medium aluminum ultrathin electronic glass, electronic grade, size 1244.6 * 1092.2 mm, 950 pieces per box, total 1291m2 per box.The thickness range is from 0.30 mm to 0.36 mm, and the thickness difference is ≤0.03 mm.

Electronic Glass is a kind of high strength touch and cover glass, which is one of the key materials of capacitive touch screen and also the protection cover glass. Widely used in smart phones, tablets, laptops, smart watches, car applications, public query systems, ATM machines, song and order system, industrial control, medical and other fields. In recent years, the demand for touch screen and cover glass is strong and growing steadily due to the increase in sales of electronic products such as smartphones and tablet computers, the increase in screen size and the development of the non-metal back cover market.

At the same time, due to its high strength, light weight and high transmission, high performance e-glass has been gradually accepted and applied in large-scale fields such as photovoltaics, new energy electric vehicles and high-speed trains, the future high-performance electronic glass products will have greater potential demand, the market prospects continue to look good.

- Q: Online LOW-E glass ok?

- Online LOW-E color monotonous, (it is said that now also developed several colors), energy-saving effect than the low two grades, and the light transmittance and color is generally dead, not adjustable, but he can be monolithic, Will not be oxidized, only those who do not require high owners and must use monolithic online LOW-E, offline color and light transmittance theoretically free to adjust, according to the owner or design preferences to adjust the energy saving effect U value Generally below 1.8, but the disadvantage is that the synthesis must be used.

- Q: Is there a way to reduce the noise

- Multi-layer composite laminated glass sound insulation effect 25 - 45 dB, the market price of about 350 --- 800 yuan / square meter Multi-layer composite laminated glass is a combination of hollow and laminated glass, this combination structure, by China's most authoritative sound insulation acoustic testing institutions - Tsinghua University Building Environmental Testing Center made a comparative test shows that multi-layer composite laminated glass is the most sound insulation performance A good combination of the structure, in the actual installation and use, such as the main road traffic, high roadside, large overpass next to the room can reach the quiet level close to the basement, this glass also has thermal insulation, energy saving Consumption, anti-theft and other functions, this is both economical and easy to expand production of noise and noise reduction glass, is vigorously for the country to promote the application of the installation of noise windows [noise glass] to become a necessary choice to ease the city noise to us The distress caused.

- Q: Ps can make the effect of architectural glass?

- Or do not think PS is not good at the field, to do other good things, after all, his most important is to adjust the color.

- Q: At present, which domestic glass steel furnace brand cost-effective? I mainly want to do architectural glass.

- We are using the North Glass

- Q: What are the equipment to build a glass factory?

- Need to slice, edging, drilling, cleaning, printing, steel and a series of equipment, the most simple operation of the initial investment of 5 million yuan.

- Q: I want to build a greenhouse and I have a very large stack of unframed panes - they need to be framed, very simply, in wood, so that they can be made into a "wall," but I can't find any instructions on how to accomplish this. Seems to me, the easiest way would be to build the wall to fit the panes, but do I need to make a slot in the boards to slide the glass into? Or should I fashion the frames some other way and then worry about fitting them into the wall, itself? Thanks for your help!

- The exact method I'd use to fabricate a wall to accept the glass panes would depend on the size of the panes. But in general, you have two basic choices on how you might cut the wood and mount the panes. One way would be to cut a groove in the center of the wood that would allow the panes to be slotted into the wood and the framework nailed together as the frames are made. You could do this and not use any putty or sealant, but the fit-up will be trickier then the next method I will suggest. What I think would be a better way is to cut a rabbit in the edges of your wood and build the wall. The rabbit should be 1/2" into the wood and at least as deep as the glass pane plus 1/8" if you want the panes to be flush with the outside edge of the wood. Your framed openings should be the same size as the glass plus 1/2" measured from the edge of the rabbit, both top to bottom and side to side. This should give you 1/4" landing of the glass to the wood with 1/4" play for any expansion/contraction. The glass can be set in putty or on a bead of sealant. Hope this helps

- Q: Effect of Moisture Content on Automotive Laminated Glass Sheet

- You said that the car laminated glass should be PVB film PVB film moisture content: the mechanical strength of laminated glass depends largely on the moisture content of PVB film, but not the film moisture content as low as possible, in the production of laminated glass, film moisture control is very important, when the water The film is too small, the film is very brittle, the strength of the laminated glass decreased significantly, and when the impact of the glass can be punctured, when the moisture content for a long time, the film and the glass between the adhesion decreased and lead to the use of degumming and foaming, The moisture content of the film for architectural glass is between 0.3% and 0.6%. In this range the film is most tightly bonded to the glass. Detection of PVB film moisture content can be used crown moisture detector

- Q: How much would it cost to build a 15 foot glass wall that is 1 inch thick and 8 feet in heigh

- I suggest you contact your local glass merchant. I am not being rude but you need more than dimensions to give you an answer. 1, First where do you live. The price in New York is likely to be different than the price in Juneau, Alaska (or in Chiang Mai Thailand where I live!) 2. Do you need a single piece of glass or a lot of smaller panes 3. What specifications for any joints? 4. Do you want the price of construction included or will you do it yourself? 5. Do you want the materials delivered or will you pick them up. 6. What about cost of transport / shipment? I hope you understand what I am getting at. There are too many factors for anyone on here to be able to help you. Therefore contact a local glass dealer and give him/her your EXACT requiremernts and they will give you the only meaningful answer that you will get.

- Q: What is the material?

- If the glass is laminated glass, then the inside should be folder semi-transparent film so become a semi-transparent glass

- Q: Why is a long time to open plastic glue, why have bubbles.

- There is a bubble may be the original glass when the glass curvature is too large, the film does not melt the air after the discharge, so there are bubbles ~ as there are bubbles, open plastic, it is difficult to appear ~

Send your message to us

0.33 mm medium aluminum ultrathin electronic glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1291 m²

- Supply Capability:

- 129100 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Bengbu CNBM Information Display Materials Co.,Ltd

Bengbu CNBM Information Display Materials Co.,Ltd