Structure Pipe

Structure Pipe Related Searches

Flexible Steel Pipe Aluminum Pipe Stock Perforated Pvc Pipe Small Bore Plastic Pipe Bondstrand Fiberglass Pipe Pipe Insulation Wrap 18 Heavy Duty Aluminum Foil 24 Heavy Duty Aluminum Foil Heavy Gauge Aluminum Foil Heavy Duty Aluminum FoilHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale Passive Solar Water Heater For Sale H4 Led Headlight Bulbs For Sale Air Pump For Aquarium Price Inverter Size For Solar System Solar Edge Inverter For Sale 5kw Solar Inverter For Sale Printed Solar Cells For SaleStructure Pipe Supplier & Manufacturer from China

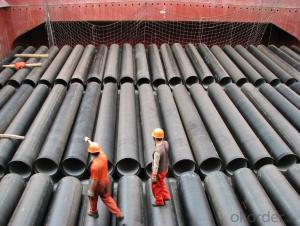

Okorder.com is a professional Structure Pipe supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Structure Pipe firm in China.Hot Products

FAQ

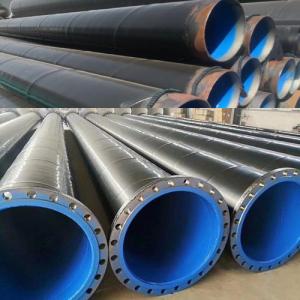

- There are several factors that can influence the lifespan of steel pipes. These factors include the quality of the steel used, the installation environment, and the maintenance and care provided to the pipes. Steel pipes are generally recognized for their durability and long life. When properly installed and regularly maintained, steel pipes can endure for many decades, sometimes even surpassing 50 years. However, it is important to consider external factors that can greatly impact their lifespan, such as corrosion, exposure to extreme temperatures, and chemical reactions. To ensure the reliability and functionality of steel pipes for an extended period, it is crucial to conduct regular inspections, make timely repairs, and apply protective coatings.

- To calculate the volume of a steel pipe, you need to know its length and the inner diameter of the pipe. The formula to calculate the volume of a cylindrical shape, like a pipe, is V = πr^2h, where V is the volume, π is a mathematical constant approximately equal to 3.14159, r is the radius of the pipe (which is half of the inner diameter), and h is the length of the pipe. Firstly, measure the inner diameter of the pipe using a measuring tape or a caliper. Divide this value by 2 to obtain the radius. Next, measure the length of the pipe in either inches, feet, or meters. Ensure that you use the same unit of measurement for both the radius and length. Once you have the radius and length, plug them into the formula V = πr^2h. For example, let's say the inner diameter of the steel pipe is 10 inches and the length is 50 feet. First, divide the inner diameter by 2 to find the radius: 10 / 2 = 5 inches. Next, convert the length to inches: 50 feet * 12 inches/foot = 600 inches. Now, plug the values into the formula: V = 3.14159 * 5^2 * 600. Calculating the volume: V = 3.14159 * 25 * 600 = 47,123.85 cubic inches. Therefore, the volume of the steel pipe is approximately 47,123.85 cubic inches.

- D108*4 what does "D108" mean by seamless steel tubes? What does "*4" mean?

- D108: refers to the outer diameter of 108mm;4: refers to the wall thickness of 4mm.

- Yes, steel pipes are generally suitable for underground irrigation pumping. They are durable, resistant to corrosion, and can withstand high pressure. Additionally, steel pipes provide excellent flow capacity, ensuring efficient water distribution for irrigation purposes.

- Yes, steel pipes can be effectively used as structural supports due to their high strength, durability, and ability to withstand heavy loads.

- Steel pipes are used in power plants for various applications. They are commonly used to transport fluids such as water, steam, and fuel in the power generation process. These pipes are essential for the safe and efficient operation of power plants, as they can withstand high temperatures and pressures. Additionally, steel pipes are used for structural purposes in the construction of power plant components such as boilers, heat exchangers, and condensers. Overall, steel pipes play a crucial role in the manufacturing and operation of power plants by facilitating the flow of fluids and providing structural support.

- Steel pipes are commonly used in the construction of irrigation systems due to their strength and durability. These pipes are used to transport water from a water source, such as a well or reservoir, to the desired areas for irrigation. They are often used in underground or above-ground applications, providing a reliable and efficient means of delivering water to crops or plants. Steel pipes are resistant to corrosion and can withstand high pressure, making them ideal for irrigation systems that require long-term functionality.

- The lifespan of steel pipes can vary depending on various factors such as the quality of the steel used, the environment in which they are installed, and the maintenance and care they receive. However, typically, steel pipes can last for several decades or even up to a century if properly installed and maintained.