Ductile Iron Pipe Fittings All Flanged Tee EN598 DN300 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Fittings Description :

Our product is an ideal material for connection, which is widely applied to construction machinery, chemical industry and other areas, especially in pipe linking system. It can be widely used under all conditions for a long time.Pipe fittings confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179,outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2.Main Features of the Ductile Iron Pipe Fittings:

Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

Standard: ISO 2531, EN545, EN598, ANSI, AWWA

Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

External coating: Zinc + Bitumen, conform to ISO8179

Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

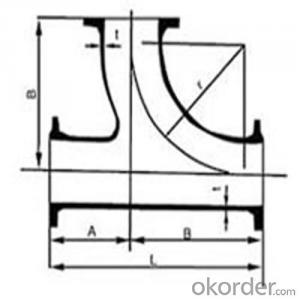

3.Ductile Iron Pipe Fittings Images:

4.Ductile Iron Pipe Fittings Specification:

Place of Origin: China (Mainland)

Model Number: DN80-1600

Standard: ISO2531 / EN545

Application: Potable/Sewage Water

Diameter: DN80-1600

Pipe Wall Thickness: standerd

5.FAQ:

1.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes fittings, improving resistance to erosion of the sewage components.

2.Q: Why would you choose ductile iron pipe fittings rather than other pipe fittings materials?

A:The reasons are obvious for that not only ductile iron pipe fittings possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems.

- Q:i keep having these like dizzy spell where the whole room gets really light and i start falling over but im able to keep myself up. it lasts like 3 minutes at the most. my neighbor told me that i might be amnemic so my mom is taking me to a doctor soon. what can i do before i get a chance to go to the doctor to get more iron. im just scared that its going to happen to me at school.

- The iron in red meat is readily absorbed so it is a good source of iron. Vitamin C also helps to absorb iron so plenty of fruit and vegetables in conjunction with red meat wil boost your iron levels. There is also plenty of iron in nuts.

- Q:What do you think are Iron Maiden's best songs?

- Be prepared to take some notes: Iron Maiden (Album): Prowler Sanctuary Remember Tomorrow Running Free Phantom of the Opera Transylvania Iron Maiden Killers: Ides of March Wrathchild Genghis Khan Killers Twilight Zone Drifter The Number of the Beast: 22 Acacia Avenue The Number of the Beast Run to the Hills Hallowed Be Thy Name Piece of Mind: Revelations Die With Your Boots On The Trooper To Tame a Land The Whole Powerslave Album Somewhere in Time: Caught Somewhere in Time Heaven Can Wait Stranger in a Strange Land Alexander the Great The Whole 7th Son of a 7th Son Album Fear of the Dark (Title Track) Brave New World: The Wicker Man Brave New World Dream of Mirrors The Nomad The Thin Line Between Love and Hate Dance of Death: Wildest Dreams Rainmaker No More Lies Montsegur Dance of Death Paschendale Face in the Sand Journeyman Any questions?

- Q:recently went vegan after being told i was iron deficient im still worried about my iron tho. i take iron vitamins everyday by nature made what should i eat ? (vegan food)

- Do not mess with ittake it to a mechanicif you pull something that you shouldnt beyou could pizz up the computer and destroy your car. Those cars are very touchy. If you dont have the finances call a garage and see what they saygood luck

- Q:Every time I iron one side of a shirt, the other side gets affected and ironing one side causes the other side to wrinkle. How do you iron properly?

- fill your iron with steam so the ironing stays in all day 1.) lay the first sleeve flat and iron it flat with a sharp crease on the top from the cuff to the shoulder then do the other sleeve 2.)do the left and right front panels using lots of steam to make sure it is crisp 3.)place the back panel over the board with the neck at the top and do the back the same wat as the panels 4.) finally iron the collar up and then iron the fold crease

- Q:I live in Germany-so there is no spray starch available, and I hate ironing because I am so bad at it. I will iron a shirt, go to hang it up, and there will still be wrinkles!

- Mary, I even have ironed for years, I starch my households outfits, iron each little thing, even my husbands t-shirts! i think of ironing technique is what's physically powerful for you, relies upon are you left exceeded, top exceeded, like the thin end of the board or the fat! it is the way I iron my husbands buttondown shirts, first, I even have my starch/water answer in a sprig bottle, I unbutton sleeves, collor and of course the shirt. I spray the back factor of the collar and iron, then spray and iron back. This places some actual ummph to the collar, yet you don't get the starch stains or fakes on the front. I do the comparable for the cuffs. After the cuffs, I iron the placard. this provides a extreme high quality stiff start up for something of your shirt.

- Q:just wondering this but where in the hell does iron from space come from??? i watched some show on the histroy channel about iron asteriods on how they could destroy earth but i did not hear on where the iron comes from. where in space?????

- Iron production is the last phase of most stars, trillions of stars have spewed untold tons of iron into space and a lot of it ends up as asteroids, once in a few million years one these asteroids hits our planet and can cause great destruction. Scientists are aware of this and there is a faint hope that we will be able to alter the path of any that are headed this way.

- Q:What is the difference between malleable iron and wrought iron?Can malleable iron be made into jewlery? Where can I buy malleable iron?

- Malleable iron is the oldest member of the family of nodular irons. Like all nodular irons, malleable iron exhibits good ductility. Incorrectly considered by some to be an old or dead material, malleable iron still has a legitimate place in the design engineer's toolbar. Malleable is the iron of choice for small castings or castings with thin cross sections (less than .25). Other nodular irons tend to be difficult to produce in these applications. Malleable iron is also preferred for castings seeing duty in low temperature environments since it retains its ductility better than other nodular irons at low temperatures. Used for small castings requiring good tensile strength and the ability to flex without breaking (ductility). Electrical fittings, hand tools, pipe fittings, washers, brackets, fence fittings, power line hardware, farm equipment, mining hardware, and machine parts. Wrought iron is commercially pure iron. In contrast to steel, it has a very low carbon content. It is a fibrous material due to the slag inclusions (a normal constituent). This is also what gives it a grain resembling wood, which is visible when it is etched or bent to the point of failure. Wrought iron is tough, malleable, ductile and easily welded. Examples of items that used to be produced from wrought iron include: rivets, chains, railway couplings, water and steam pipes, raw material for manufacturing of steel, nuts bolts, horse shoe bars, handrails, straps for timber roof trusses, boiler tubes, and ornamental ironwork.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Pipe Fittings All Flanged Tee EN598 DN300 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords