Hollow Section with Different Specifications from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

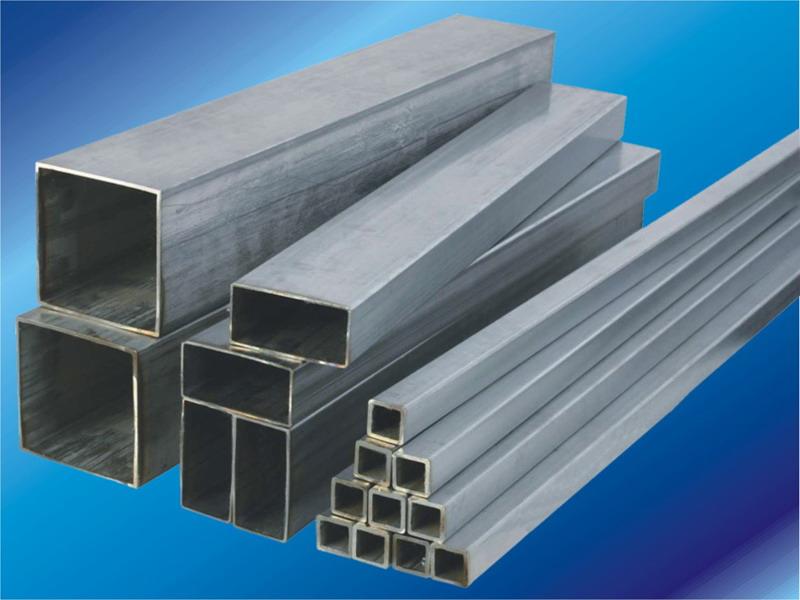

1、Structure of Hollow Section Description:

Hollow section is a type of metal profile with a hollow tubular cross section. Hollow section, especially rectangular sections, are commonly used in welded steel frames where members experience loading in multiple directions. Square and circular hollow section have very efficient shapes for this multiple-axis loading as they have uniform geometry along two or more cross-sectional axes, and thus uniform strength characteristics. This makes them good choices for columns. They also have excellent resistance to torsion. Hollow section can also be used as beams, although wide flange or I-beam shapes are in many cases a more efficient structural shape for this application. However, the hollow section has superior resistance to lateral torsional buckling.

2、Main Features of the Hollow Section:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

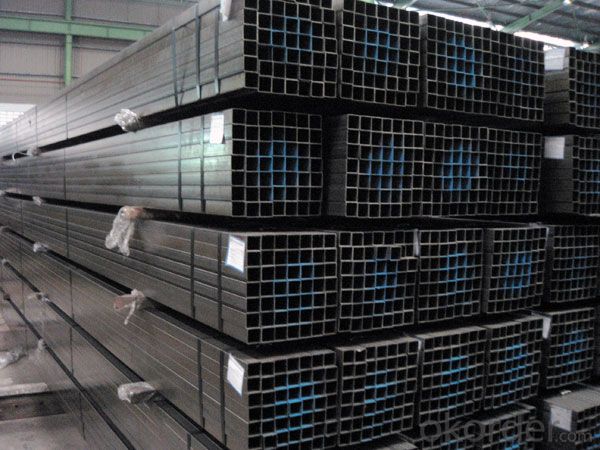

3、Hollow Section with Different Specifications Images:

4、Hollow Section Specifications:

Standard: | JIS, GB, DIN, ASTM JIS G3445-2006, JIS G3444-2006, JIS G3446-2004, JIS G3441, GB/T 8163-1999, GB/T 8162-1999, DIN EN 10216-1-2004, DIN EN 10217-1-2005, DIN EN 10305, ASTM A106-2006, ASTM A53-2007, ASTM A789-2001, ANSI A213-2001, ASTM A179-1990 |

Grade: | 10#-45#, Cr-Mo alloy, Mo 10#, 20#, 45#, 15CrMo, 12CrMo, 13CrMo44, 12CrMo195, 16Mo, 16mo3 |

Thickness: | 1 - 50 mm |

Section Shape: | Square |

Outer Diameter: | 15*15---80*80 |

Place of Origin: | Shandong, China (Mainland) |

Secondary Or Not: | Non-secondary |

Application: | Structure Pipe |

Technique: | Hot Rolled |

Surface Treatment: | Copper Coated |

| Certification: | API |

| Special Pipe: | Thick Wall Pipe |

Alloy Or Not: | Non-alloy |

authentication:CANS CNAB IAF PAC CEC

5、FAQ of Hollow Sections with Different Specifications:

①How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.

③ How can we get more information?

You can contact us by Email or call us directly and we will do our best to give you valuable information as much as possible but this service is not available on weekends.

- Q:What place must use galvanized steel pipe to make lighting line?

- Galvanized pipe for pipeline laying construction and transformation of lighting, power, telephone, fire protection system in the engineering (made of galvanized steel), for laying, laying can be laid in the dark, the wall can also be installed on the ceiling.

- Q:What are the advantages of using steel pipes in the manufacturing of furniture?

- There are several advantages of using steel pipes in the manufacturing of furniture. Firstly, steel pipes offer exceptional strength and durability, ensuring that the furniture will be long-lasting and capable of withstanding heavy use. Secondly, steel pipes are highly resistant to corrosion, making them suitable for both indoor and outdoor furniture. Additionally, steel pipes provide a sleek and modern aesthetic, adding a touch of sophistication to the furniture design. Lastly, steel pipes are relatively lightweight compared to other materials like wood or concrete, making transportation and installation easier. Overall, using steel pipes in furniture manufacturing offers a combination of strength, durability, aesthetic appeal, and practicality.

- Q:How are steel pipes used in nuclear power plants?

- Steel pipes are used in nuclear power plants for various purposes, including transporting coolant, steam, and other fluids, as well as providing structural support for the plant's infrastructure.

- Q:How are steel pipes protected against microbial corrosion?

- Steel pipes are protected against microbial corrosion through various methods, such as applying protective coatings or linings on the pipes' inner and outer surfaces. These coatings act as a barrier, preventing the contact of microorganisms with the steel surface, thereby reducing the risk of microbial corrosion. Additionally, biocides and inhibitors can be added to the pipe's contents or injected into the pipeline to inhibit the growth and activity of microbes, further protecting the steel pipes from microbial corrosion.

- Q:What is the composition of steel pipes?

- Steel pipes are primarily composed of iron and carbon, with small amounts of other elements such as manganese, silicon, and traces of sulfur and phosphorus.

- Q:What are the common standards for coating and lining of steel pipes?

- The most common standards for coating and lining of steel pipes include the American Petroleum Institute (API) standards such as API 5L, API 5CT, and API 5LD. Other widely recognized standards include the American Water Works Association (AWWA) standards such as AWWA C210 and AWWA C213, as well as the National Association of Corrosion Engineers (NACE) standards such as NACE RP0188 and NACE RP0394. These standards ensure the proper selection, application, and performance of coatings and linings to protect steel pipes from corrosion and other external factors.

- Q:What is the fire rating of steel pipes?

- The fire rating of steel pipes depends on several factors. Steel is inherently fire-resistant due to its high melting point and low thermal conductivity. However, the fire rating of steel pipes can be further enhanced through the use of fire-resistant coatings or insulation materials. These additional measures can provide varying degrees of fire protection, typically measured in terms of the duration the pipes can maintain their structural integrity in a fire scenario. The specific fire rating of steel pipes can vary depending on the thickness and type of coating or insulation used. It is important to consult industry standards, such as those set by organizations like the National Fire Protection Association (NFPA), or consult with fire safety professionals to determine the appropriate fire rating requirements for specific applications.

- Q:How are steel pipes classified based on their end connections?

- Steel pipes can be classified based on their end connections into three main categories: threaded, socket-weld, and butt-weld.

- Q:How to make the magnetic steel, can be like a magnet?

- Of course, not all materials can be magnetized, austenitic stainless steel will not do.

- Q:What is the difference between steel pipes and PVC-O pipes?

- The main difference between steel pipes and PVC-O pipes is the material they are made of. Steel pipes are made of metal, specifically steel, which gives them high strength and durability. On the other hand, PVC-O pipes are made of a type of plastic called polyvinyl chloride, which is reinforced with oriented molecules, making them extremely strong and resistant to both internal and external pressures. Additionally, steel pipes are prone to corrosion, while PVC-O pipes are resistant to rust and chemical degradation. PVC-O pipes are also lighter and easier to handle and install compared to steel pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hollow Section with Different Specifications from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords