Scaffolding Building Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Scarffolding Building Structure Pipe:

1) Standard: BS EN39 Loose steel tubes for tube and coupler scaffolds -- Technical delivery conditions

other size also can be manufactured, please contact us for detail information.

2) Surface Treatment: Galvanized , Oiled, Painted , Bare

3) End treatment: Beveled , Plain , Threaded

4) Test: Chemical Component Analysis, Mechanical Properties, Technical Properties, Exterior Size Inspection

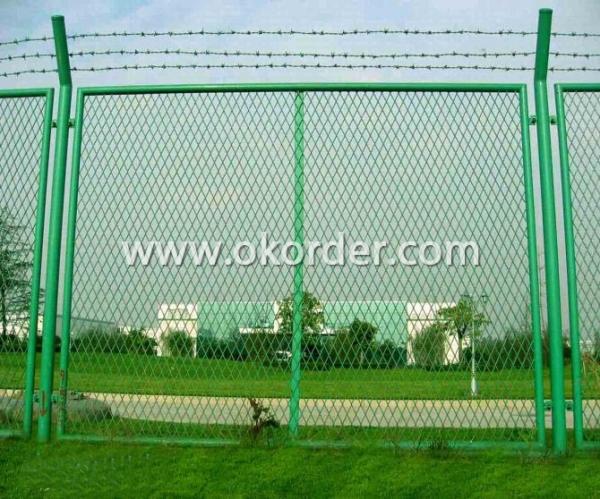

5)Application: Fence, Construction.

6)Certificate: SGS Inspection

7)Delivery Time: usually in 20--30 days

8) Payment Term: T/T , L/C

Application of Galvanized , Oiled, Painted , Bare Scaffolding Building Structure Pipe BS EN39, A500 A,B,C, D.

A53 A,B.S275, S355, C250, C350

2. Tecnical Data:

Chemical Composition of Raw Materials | Mechanical Property of Raw Materials | ||||||||||

Item | Chemical Composition % | Item | Mechanical Property | ||||||||

Steel | Steel No. | C | Mn | S | P | Si | Al | Steel | Yield point Mpa min | Tensile Strength Mpa | Elongation % min |

S235GT | 1.0106 | < 0.20 | < 1.40 | < 0.045 | < 0.040 | < 0.05 | > 0.020 | S235GT | 235 | 340--520 | 24 |

Other material: A500 A, B, C , D. A53 A, B. S275, S355, C250, C350 | |||||||||||

3. Standard Size for Reference

OD (mm) | WT(mm) | L (mm) | Tolerance (min) (mm) | Zinc Coating g/m2 |

48 -- 48.6 | 2--7 | 300 -- 6000 | WT +/- 0.2 , L - 0 -- + 3 | 280--400 |

application of scaffolding pipe (ERW welded pipe)

- Q:How do steel pipes perform in high-altitude applications?

- Steel pipes perform well in high-altitude applications due to their strong structural integrity and resistance to extreme weather conditions. They can withstand the low temperatures and high winds commonly found at high altitudes without compromising their performance or durability. Additionally, steel pipes have excellent corrosion resistance, making them suitable for areas with high humidity or exposure to moisture. Overall, steel pipes are a reliable choice for high-altitude applications due to their strength, resilience, and ability to withstand harsh environmental factors.

- Q:Can steel pipes be used for hydropower systems?

- Hydropower systems can indeed utilize steel pipes. For a variety of purposes in these systems, steel pipes are commonly employed, particularly for penstocks, which facilitate the transportation of water from a reservoir to a turbine. The strength, durability, and capacity to withstand high pressure and water flow make steel pipes a preferred option. Additionally, their resistance to corrosion ensures their suitability for long-term usage in hydropower systems. Moreover, the ease of welding or joining steel pipes enables flexibility in system design and installation. In summary, steel pipes are a dependable and extensively utilized alternative for hydropower systems.

- Q:Can steel pipes be threaded?

- Yes, steel pipes can be threaded. Threading is a common process used to create screw-like ridges on the ends of the steel pipes, allowing them to be easily connected to fittings or other pipes.

- Q:The outer circle of a seamless steel pipe 50 head into the outer circle of the 40 to close

- That is, according to the production process of different classification, different from hot rolling (expansion) pipe. In the process of expanding the tube or raw material tube, it is processed by multiple cold drawing, usually on single chain or double chain cold drawn machine of 0.5 ~ 100T. Cold rolled steel pipe (DIAL) in general, steel pipe for low and medium pressure boiler tube, high-pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking tube, machining pipe, thick wall pipe, small diameter and cold drawn steel tube also includes other tubes, carbon thin-walled steel, alloy thin-walled steel pipe, stainless steel pipe, special-shaped wall steel pipe. The outside diameter of cold drawn steel tube wall thickness to 6mm, to 0.25mm, to 5mm diameter thin-walled tube wall thickness is less than 0.25mm in size, accuracy and surface quality were significantly better than the hot (expanding) tube, but by the process control, its diameter and length are limited.

- Q:What are steel pipes made of?

- Steel pipes are primarily made of steel, which is an alloy composed of iron and carbon.

- Q:Can steel pipes be used for piling?

- Yes, steel pipes can be used for piling. Steel pipes are commonly used in piling applications due to their strength, durability, and versatility. They are able to withstand the load and pressure of the soil and provide a stable foundation for structures. Steel pipes used for piling are typically driven into the ground using specialized equipment, ensuring they are securely positioned. Additionally, steel pipes can be easily cut and welded to the required length, making them suitable for various piling projects.

- Q:What are the different methods of pipe support for steel pipes?

- There are several different methods of pipe support for steel pipes, each designed to ensure the stability, alignment, and protection of the pipes. Some of the most commonly used methods include: 1. Pipe Hangers: These are devices that suspend or support the weight of the pipe from above. They are typically made of metal and can be adjustable or fixed, allowing for easy installation and maintenance. Pipe hangers can be used in various configurations, such as clevis hangers, beam clamps, or pipe rollers, depending on the specific application. 2. Pipe Shoes: These are supports that are directly attached to the bottom of the pipe, providing a stable resting surface. Pipe shoes are usually made of steel or other durable materials and are designed to prevent pipe movement, absorb vibrations, and distribute the weight evenly. They are commonly used in applications where pipes are subjected to high temperatures or where there is a need for thermal expansion. 3. Pipe Clamps: These are devices used to hold or fasten the pipes together or to a structure. Pipe clamps are typically made of metal and come in various sizes and designs to accommodate different pipe diameters and configurations. They provide support and prevent the pipes from sagging or moving, especially in areas where there are changes in direction or elevation. 4. Pipe Racks: These are structures that are specifically designed to support multiple pipes in an organized and secure manner. Pipe racks are commonly used in industrial settings, such as refineries or power plants, where large quantities of pipes need to be stored or supported. They are typically made of steel and can be customized to accommodate different pipe sizes and layouts. 5. Pipe Guides: These are devices that help guide and control the movement of the pipe, especially during thermal expansion or contraction. Pipe guides are typically fixed to the structure and provide a sliding surface to allow for the longitudinal movement of the pipe. They are commonly used in applications where there are changes in temperature, such as in steam or hot water systems. These are just a few of the many methods of pipe support for steel pipes. The choice of support method depends on factors such as pipe size, weight, temperature, and the specific requirements of the application. It is crucial to select the appropriate support method to ensure the longevity and integrity of the pipes and to prevent any potential issues such as sagging, misalignment, or failure.

- Q:Can steel pipes be used for underground cable ducting?

- Underground cable ducting can utilize steel pipes, as they possess durability and strength. Due to their robustness, steel pipes commonly serve as a protective casing for cables, warding off potential harm from external factors like moisture, pressure, and environmental elements. Moreover, steel pipes exhibit resistance to corrosion, rendering them suitable for extended underground use. In addition, their ability to withstand heavy loads deems them ideal for areas where cables may face high pressure or weight. Nevertheless, before selecting steel pipes for underground cable ducting, it is vital to take into account soil conditions, installation requirements, and the specific needs of the cable system.

- Q:How are steel pipes used in the manufacturing of desalination plants?

- Steel pipes are used in the manufacturing of desalination plants to transport the seawater from the intake point to the treatment facilities. These pipes are durable, corrosion-resistant, and can withstand the high-pressure conditions required for the desalination process.

- Q:What are the different types of steel pipe caps?

- There exists a variety of steel pipe caps, each serving specific purposes and applications. A few commonly used types are as follows: 1. Threaded Caps: These caps possess internal threads that enable them to be screwed onto threaded pipes, ensuring a secure seal. They find frequent usage in plumbing and gas-related tasks. 2. Socket Weld Caps: These caps are designed for welding onto pipe ends using a socket weld connection. They offer a strong and permanent seal, rendering them suitable for high-pressure and high-temperature tasks. 3. Butt Weld Caps: Butt weld caps, similar to socket weld caps, are meant for welding onto pipe ends. However, they are specifically designed for butt welding, which involves directly welding the cap to the pipe without additional fittings. 4. Domed Caps: These caps have a domed or rounded shape on the upper surface, providing a smooth and visually pleasing finish. They are commonly applied in architectural and decorative tasks, such as handrails or fence posts. 5. Flat Caps: As the name suggests, flat caps possess a flat upper surface. They are often utilized when a simple and low-profile cap is required, such as for safeguarding pipe ends in industrial applications. 6. Blind Caps: Blind caps are employed to permanently seal off pipe ends. They are solid caps without any openings or threads, ensuring complete closure. They are frequently utilized in piping systems where a section of the pipeline is not in use or temporarily needs to be closed off. These examples merely scratch the surface of the various steel pipe caps available. The selection of a cap depends on specific application requirements, including the type of connection, pressure, temperature, and the necessity for structural or decorative finishes. It is crucial to choose the appropriate cap to guarantee a secure and reliable seal for the pipe.

1. Manufacturer Overview |

|

|---|---|

| Location | Tianjin, China |

| Year Established | 1997 |

| Annual Output Value | Above Three Million To Five Million RMB |

| Main Markets | Main land |

| Company Certifications | ISO 9001:2010;API 5L; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 40% - 50% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Scaffolding Building Structure Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords