Stainless Steel Piping

Stainless Steel Piping Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Piping Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Piping supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Piping firm in China.Hot Products

FAQ

- Yes, steel pipes are suitable for underground cable protection. Steel pipes provide excellent mechanical strength and durability, protecting cables from external forces such as ground movement or accidental damage. They also offer resistance to corrosion, making them a reliable choice for long-term cable protection in underground installations.

- Steel pipes find extensive use in mining operations for a range of purposes. In mining, one of the primary applications of steel pipes involves the transportation of materials, including water, slurry, and other liquids. These pipes possess exceptional durability and can withstand the harsh conditions typically encountered in mining environments, rendering them highly suitable for long-distance material conveyance. Furthermore, steel pipes serve as crucial components in mining ventilation systems. The provision of fresh air to workers and the elimination of harmful gases and dust are of paramount importance in the mining industry. Steel pipes are employed in the construction of ventilation shafts and ducts, facilitating the airflow throughout the mine and ensuring the safety of the miners in their working environment. Moreover, steel pipes contribute significantly to the construction of underground tunnels and mine shafts. By providing structural support and reinforcement, they effectively prevent collapses and maintain the stability of the mine. The strength and durability inherent in steel pipes make them the ideal choice for these critical applications in mining. Another noteworthy use of steel pipes in mining is for the extraction of resources. In certain instances, steel pipes are deployed to establish boreholes or wells, enabling access to underground deposits of minerals or water. Inserted into the ground, these pipes are instrumental in employing various techniques such as drilling or hydraulic fracturing to extract the desired resources. In summary, steel pipes play an indispensable role in the mining industry, serving an array of purposes, including material transportation, ventilation, structural support, and resource extraction. Their strength, durability, and ability to withstand adverse conditions make them an indispensable asset in mining operations.

- How many fasteners are there in a ton of steel tubes?

- In general, 180-200 fasteners per ton of steel pipe.

- Steel pipes are commonly used in the construction of railways and transportation systems for various purposes. One major use of steel pipes in these applications is for the construction of bridges and tunnels. Steel pipes are often used as structural components in the construction of bridges, providing support and stability to the overall structure. In tunnels, steel pipes are used as ventilation shafts, allowing for the circulation of air and removal of fumes, thus ensuring the safety of passengers and workers. Additionally, steel pipes are used for the construction of railway tracks. They are used as supports for the tracks, providing a stable base for the trains to travel on. Steel pipes used in railway tracks are typically coated or galvanized to protect them from corrosion and ensure their longevity. Moreover, steel pipes are used for drainage systems in railway stations and transport hubs, ensuring proper water management and preventing flooding. Another important application of steel pipes in transportation systems is for the construction of signposts and streetlights. Steel pipes are often used as the main structural element in these structures, providing strength and durability. They can be easily fabricated and shaped to meet the specific design requirements, making them a popular choice for these applications. Overall, steel pipes play a crucial role in the construction of railways and transportation systems by providing structural support, ensuring proper ventilation, facilitating drainage, and serving as the main components in various structures. Their strength, durability, and versatility make them an ideal choice for these applications, contributing to the safe and efficient operation of transportation networks.

- The impact of temperature on steel pipes can vary depending on the specific conditions and application. Generally, high temperatures can cause steel pipes to expand, potentially leading to buckling or distortion. On the other hand, extremely low temperatures can make steel pipes more brittle and prone to cracking. It is crucial to consider the temperature range within which the steel pipes will operate to ensure their structural integrity and prevent any potential failures.

- What are the main types of steel pipe ah? How to judge which kind of steel pipe performance is better?

- Steel pipe according to the production method can be divided into two categories: seamless steel pipe and pipe joints, pipe joints as welded steel pipe.1. seamless steel tube according to the production methods can be divided into: hot-rolled seamless pipe, cold drawn tube, precision steel tube, heat expansion tube, cold spinning tube and extrusion tube.Seamless steel tubes are made of high quality carbon or alloy steel. They are hot-rolled and cold-rolled (drawn).Bundled steel pipe

- There are several types of joints commonly used to connect steel pipes, including threaded joints, flanged joints, welded joints, and mechanical joints. Each type of joint has its own advantages and is chosen based on factors such as the application, pipe size, and pressure requirements.

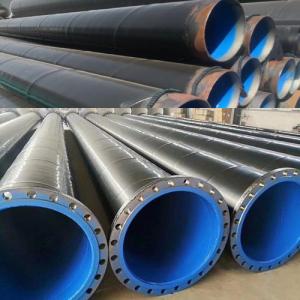

- Steel pipes are commonly insulated to prevent freezing by applying a layer of insulation materials, such as foam or fiberglass, around the pipes. This insulation helps to maintain the temperature of the pipes and prevents heat loss, thus preventing the water inside from freezing during cold weather conditions. Additionally, heat tracing cables can be used along with the insulation to provide an extra layer of protection by supplying heat to the pipes.