Longtudenal Submerged ARC Welded LSAW Steel Pipe

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

● Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

● All round supports ensure your business’ safety & interest of all time

▲ CNBM is a state owned enterprise, which background ensures it of funds support and preferential policies

provide by ministry of commerce.

▲ CNBM enjoys a sound reputation both at home and aboard. The company stands a first-rate credit status

and has gained the access to preferential loans through a lot of international banking organizations.

▲ The company is renowned of it manufacturing capabilities and overall sourcing abilities. It has a long

track proven record of strategic cooperation with leading players in steel industry.

▲ Brand name “CMAX” commit to the best quality products and high cost effectiveness which ensures your

company a booming development & success.

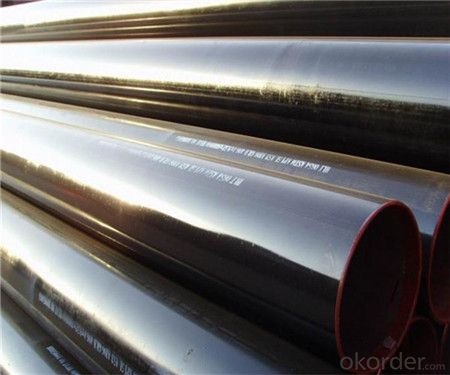

6、Seamless Pipe ASTM A106/53 Images:

- Q:What does "1.5" steel tube mean?

- 1.5 inch [1 1/2 steel pipe, outer diameter 48.3mm, 1.5 inches, refers to the pipe bore is approximately the inner diameter (25.4x1.5 = 38.1mm). [DN40] the specific parameters of the steel pipe are as follows;The average wall thickness is: 3.5mm;The minimum wall thickness is 3.06mm,Nominal diameter is 40mm,External Jing is 48.3mm,

- Q:What are the dimensions of steel pipes?

- The dimensions of steel pipes can vary depending on the specific requirements and industry standards. However, steel pipes typically have standardized dimensions in terms of their outer diameter (OD), wall thickness, and length. The outer diameter of steel pipes can range from small sizes, such as ¼ inch (6.35 mm) or ⅛ inch (3.175 mm), to larger sizes like 48 inches (1219.2 mm) or even more for specialty applications. The wall thickness of steel pipes can also vary greatly, with options ranging from thin-walled pipes with a few millimeters of thickness to thick-walled pipes with several inches of thickness. In terms of length, steel pipes are typically produced in standard lengths of 20 feet (6.1 meters) or 40 feet (12.2 meters). However, custom lengths can also be manufactured based on specific project requirements. It is important to note that these dimensions are just general examples and may not cover all the possible variations in steel pipe sizes. Therefore, it is always recommended to consult relevant industry standards and specifications to determine the precise dimensions required for a particular application.

- Q:What is the flexibility of steel pipes?

- Steel pipes possess exceptional flexibility, rendering them highly versatile and suitable for a wide array of applications. Their flexibility is derived from the inherent properties of steel, such as its high tensile strength and ductility, enabling them to bend and endure various forms of stress without breaking or deforming. The structural integrity of steel pipes remains intact even when bent or shaped into different forms. This facilitates simpler installation and routing around obstacles, making them more adaptable for intricate plumbing or piping systems. Furthermore, the flexibility of steel pipes allows them to withstand external forces like ground movements or temperature fluctuations without sustaining significant damage. Moreover, the flexibility of steel pipes makes them ideal for applications that involve dynamic movement or expansion. In the case of oil and gas pipelines or heating and cooling systems, where temperature variations can lead to expansion and contraction, steel pipes can accommodate these changes without causing leaks or failures. Additionally, the flexibility of steel pipes contributes to their durability and longevity. The ability to endure bending and stress prevents the formation of cracks or fractures that could result in leaks or structural failures. This characteristic establishes steel pipes as a dependable choice for demanding environments, including high-pressure systems or corrosive conditions. To sum up, the flexibility of steel pipes is a crucial attribute that allows for effortless installation, adaptability to diverse conditions, and long-term reliability. Due to their remarkable flexibility, steel pipes are extensively preferred in numerous industries and applications where strength, durability, and versatility are paramount.

- Q:How are steel pipes protected against abrasive wear?

- Steel pipes are protected against abrasive wear through various methods such as applying protective coatings, using abrasion-resistant liners, and implementing proper maintenance and monitoring practices.

- Q:What does "steel pipe SC" mean?

- DN100 and "SCH80" refer to the outer diameter and the wall thickness of the steel pipe;

- Q:Can steel pipes be used for underground stormwater systems?

- Yes, steel pipes can be used for underground stormwater systems. Steel pipes are known for their durability and strength, making them suitable for withstanding the pressure and weight of underground stormwater systems. Additionally, steel pipes have a high resistance to corrosion, which is important when dealing with stormwater that may contain various contaminants. However, it is important to properly coat and protect the steel pipes to prevent any potential corrosion or damage over time. Regular maintenance and inspections should also be carried out to ensure the integrity of the steel pipes and the overall performance of the underground stormwater system.

- Q:What are the different standards and specifications for steel pipes?

- There are several different standards and specifications for steel pipes, including ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and ANSI (American National Standards Institute). These standards outline the requirements for various aspects of steel pipes such as dimensions, material composition, mechanical properties, and testing methods. Additionally, there are specific standards for different applications, such as oil and gas pipelines, structural pipes, and water supply systems, which further define the specifications and performance criteria for steel pipes.

- Q:How are steel pipes used in the construction of oil refineries?

- Steel pipes are extensively used in the construction of oil refineries for various purposes. They are primarily used for transporting crude oil, refined petroleum products, and various chemicals within the refinery complex. Steel pipes are also utilized for the distribution of water, steam, and other fluids required for the refining processes. Additionally, they are employed in the construction of equipment such as heat exchangers, reactors, and storage tanks, where they provide structural support and ensure efficient fluid flow. Overall, steel pipes play a critical role in the reliable and safe operation of oil refineries.

- Q:What are the different types of steel pipe coatings for corrosion protection?

- There are several types of steel pipe coatings used for corrosion protection, including epoxy coatings, polyethylene coatings, zinc coatings, and coal tar coatings. Each coating offers different levels of protection and is chosen based on the specific application and environmental conditions.

- Q:What is the difference between steel pipes and FRP pipes?

- Steel pipes and FRP (Fiber Reinforced Plastic) pipes are two different types of pipes that are commonly used in various industries and applications. Here are the key differences between the two: 1. Material Composition: Steel pipes are made of steel, which is an alloy of iron and carbon, with additional elements like manganese, silicon, and traces of other metals. On the other hand, FRP pipes are composed of a polymer matrix reinforced with fibers, such as glass or carbon fibers. 2. Strength and Durability: Steel pipes are known for their high strength and durability. They can withstand high pressures, heavy loads, and extreme temperatures. FRP pipes, although strong and durable, are comparatively lighter in weight and may not have the same level of strength as steel pipes. However, they are corrosion-resistant and have a longer lifespan in corrosive environments. 3. Corrosion Resistance: Steel pipes are prone to corrosion and require protective coatings or linings to prevent rust and deterioration. FRP pipes, on the other hand, are inherently corrosion-resistant. They do not require additional coatings and are suitable for transporting corrosive fluids or operating in corrosive environments. 4. Installation and Maintenance: Steel pipes require specialized welding or threading techniques for installation. They can be more labor-intensive and time-consuming to install, especially in complex or large-scale projects. FRP pipes, on the other hand, are lightweight and can be easily transported and installed. They often come in pre-fabricated sections, making installation faster and less labor-intensive. Additionally, FRP pipes require minimal maintenance compared to steel pipes. 5. Cost: Steel pipes are generally more expensive than FRP pipes due to the higher cost of raw materials and the need for additional corrosion protection measures. FRP pipes offer a cost-effective alternative, especially in applications where corrosion resistance is essential, as they eliminate the need for expensive coatings or linings. Overall, the choice between steel pipes and FRP pipes depends on the specific requirements of the application. Steel pipes are preferred for their high strength, while FRP pipes offer benefits such as corrosion resistance, lightweight, and cost-effectiveness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Longtudenal Submerged ARC Welded LSAW Steel Pipe

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords