Spot 20# seamless steel tube high pressure seamless steel tube Q345B seamless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

- Option:

- 76*5 89*6 Other size please phone me 114*8 133*10 108*8

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

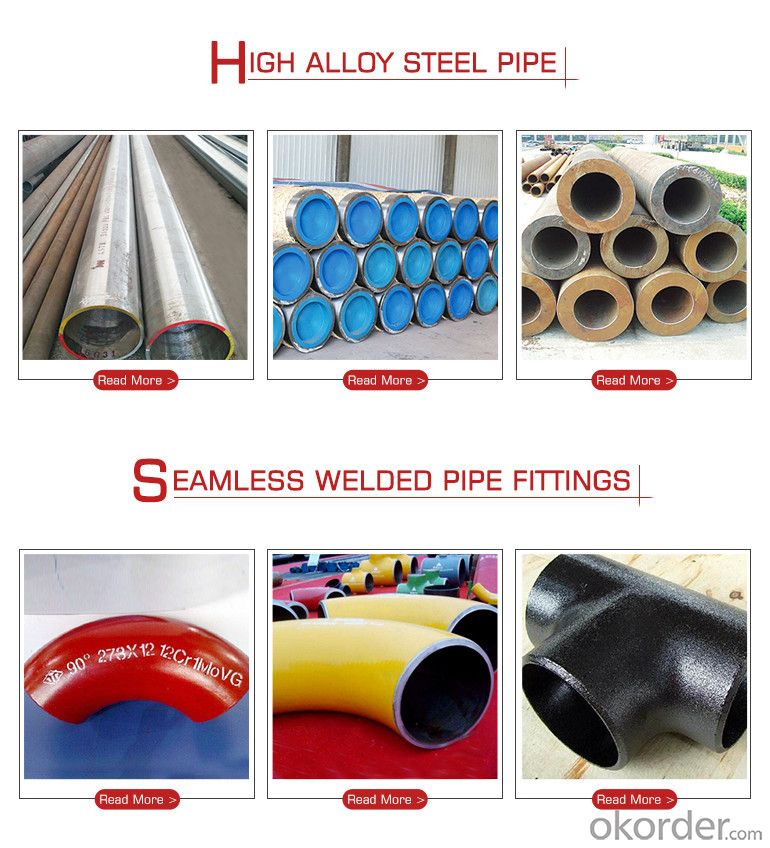

Main materials :10#, 20#, 35#, 45#, 20G, 40Cr, 20Cr, 16mn-45mn, 27SiMn, Cr5Mo, 12CrMo(T12), 12Cr1MoV, 12Cr1MoVG, 10CrMo910, 15CrMo, 35CrMo, 40CrMo, etc.

1. Seamless tubes for construction (GB/ t8162-2008) are seamless tubes for general construction and mechanical construction.

2. Seamless pipe for fluid transportation (GB/ t8163-2008) is a normal seamless pipe for the transportation of water, oil, gas and other fluids.

3. Seamless tube for low and medium pressure boiler (gb3087-2008) is a kind of seamless tube for hot rolling and cold drawing (rolling) of excellent carbon structure steel, which is used for making all kinds of superheated steam tube, boiling water tube, superheated steam tube for locomotive boiler, big pipe, small pipe and arch brick.

4. Seamless tube for high-pressure boiler (gb5310-2008) is a seamless tube of excellent carbon steel, alloy steel and stainless heat-resistant steel for the heating surface of water-tube boiler with high pressure and above pressure.

5. High pressure seamless tubes for fertilizer equipment (gb6479-2000) are excellent carbon structural steel and alloy steel seamless tubes suitable for chemical equipment and pipelines with operating temperature of -40~400℃ and working pressure of 10~30Ma.

6. Seamless tubes for petroleum cracking (gb9948-2006) are seamless tubes for furnace tubes, heat exchangers and pipelines used in petroleum refineries.

7. The steel pipe for geological drilling (yb235-70) is the steel pipe for core drilling in geological part, which can be divided into drill pipe, drill collar, core pipe, casing pipe and deposition pipe, etc.

8. Seamless pipe for diamond core drilling (gb3423-82) is a seamless pipe for drilling drill pipe, core rod and casing for diamond core drilling.

9. The oil drilling pipe (yb528-65) is a seamless pipe with internal or external thickening at both ends for oil drilling.

10. Seamless carbon steel tubes for ships (gb5312-85)

11.Seamless steel tubes (GB/ t18984-2003) for cryogenic piping are used for -45℃ ~ -195℃ cryogenic pressure vessel piping and cryogenic heat exchanger piping

company introduction:

Our company is a new force established by the pipe industry group founded in the 1980s. Relying on a large number of core technologies accumulated by the group, as well as strict quality control, physical and chemical testing, it carries out professional pipe fitting management in strict accordance with various standards.Products are widely used in petroleum, petrochemical, chemical, thermal power, boiler, four pipelines, fertilizer, aviation nuclear power, metallurgy, shipbuilding, machinery and military fields.

The main products of our company mainly include elbow, elbow, tee, reducing pipe, pipe cap, sharp elbow, flange, socket, forged pipe fittings and difficult pipe fittings.In addition, our company always has alloy steel tubes, seamless steel tubes for high-pressure boilers.Middle and low pressure boiler tube, low temperature steel tube, pipeline steel tube and so on after 10,000 tons.

- Q:What are the different types of steel pipe tees?

- There are three main types of steel pipe tees: equal tee, reducing tee, and barred tee.

- Q:Is the diameter of the steel tube indicated by the outer diameter by the wall thickness or by the inside diameter by the wall thickness?

- The specification for steel tubes is the outer diameter multiplied by the wall thickness.Generally speaking, the diameter of the pipe can be divided into outer diameter (De), inner diameter (D) and nominal diameter (DN).

- Q:How are steel pipes used in automotive manufacturing?

- Steel pipes are commonly used in automotive manufacturing for various applications such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and corrosion resistance, making them suitable for withstanding the harsh conditions and high temperatures associated with automotive operations. Additionally, steel pipes offer flexibility in design and can be easily formed and manipulated to meet specific requirements, ensuring efficient and reliable performance in vehicles.

- Q:Can steel pipes be used for brewery installations?

- Yes, steel pipes can be used for brewery installations. Steel pipes are often used in breweries for various applications such as transferring fluids, connecting equipment, and creating plumbing systems. Steel pipes are known for their durability, strength, and resistance to corrosion, which makes them suitable for handling the harsh conditions and high-pressure environments typically found in brewery installations. Additionally, steel pipes can be welded together, allowing for seamless connections, ensuring a reliable and leak-free operation. However, it is important to ensure that the steel pipes used in brewery installations meet the necessary standards and regulations to ensure the safety and quality of the beer production process.

- Q:What are the advantages of using steel pipes in plumbing systems?

- There are several advantages of using steel pipes in plumbing systems. Firstly, steel pipes are highly durable and can withstand high levels of pressure, making them suitable for carrying water and other fluids. Additionally, steel pipes are resistant to corrosion, which ensures longevity and prevents leaks. Steel pipes also have a smooth interior surface, which improves water flow and reduces the risk of blockages. Moreover, steel pipes are fire-resistant and do not contribute to the spread of flames, enhancing overall safety. Lastly, steel pipes are environmentally friendly as they are often made from recycled materials and can be recycled again at the end of their lifespan.

- Q:What are the different types of connections used with steel pipes?

- There are several types of connections commonly used with steel pipes, including threaded connections, welded connections, flanged connections, and grooved connections.

- Q:What are the different factors affecting the flow rate of steel pipes?

- The flow rate of steel pipes can be affected by multiple factors. Let's explore some of these factors: 1. Pipe diameter: The size of the pipe plays a significant role in determining the flow rate. Generally, larger pipes allow for greater flow rates as they provide a larger cross-sectional area for the fluid to pass through. 2. Pipe length: The length of the pipe also impacts the flow rate. Longer pipes tend to have higher friction losses, which can decrease the flow rate. Moreover, longer pipes may require higher pressure to maintain the desired flow rate. 3. Fluid viscosity: The viscosity of the fluid passing through the pipe is an important consideration. Viscous fluids, such as heavy oils, exhibit higher resistance to flow, resulting in lower flow rates. Conversely, less viscous fluids, like water, encounter lower resistance and can achieve higher flow rates. 4. Pressure difference: The pressure difference across the pipe serves as a driving force for flow. A higher pressure difference will lead to a higher flow rate, while a lower pressure difference will reduce the flow rate. 5. Surface roughness: The roughness of the inner pipe surface influences the flow rate. Rough surfaces generate more turbulence and friction, thus resulting in a lower flow rate. Conversely, smoother surfaces minimize turbulence and friction, allowing for a higher flow rate. 6. Temperature: The temperature of the fluid can impact its viscosity and density, which subsequently affect the flow rate. Higher temperatures generally decrease the viscosity of fluids, leading to increased flow rates. 7. Pipe material: The choice of pipe material impacts the flow rate due to varying roughness and resistance. Steel pipes, for instance, typically possess a smoother inner surface compared to pipes made of other materials, resulting in higher flow rates. 8. Pipe fittings and bends: The presence of fittings, valves, and bends in the pipe can cause flow restrictions and pressure drops, which can decrease the flow rate. Proper design and placement of these components can minimize their impact on the flow rate. Understanding the interplay of these factors is essential for the design and optimization of fluid flow systems involving steel pipes.

- Q:Can steel pipes be used for underground fuel storage tanks?

- Underground fuel storage tanks can indeed utilize steel pipes. These pipes find wide application in various fields, including underground fuel storage tanks. Their strength, durability, and resistance to corrosion enable them to serve as suitable long-term storage options for fuels like gasoline, diesel, and oil. Moreover, the weldability of steel pipes allows for the creation of seamless and secure tank structures. Nevertheless, it is crucial to ensure that the steel pipes employed in underground fuel storage tanks are appropriately coated with corrosion-resistant materials. This precautionary measure shields the pipes from potential damage that may arise due to exposure to moisture or the chemicals present in the fuel. Consistent inspection and maintenance procedures are also imperative to uphold the tank's integrity and avert leaks or environmental hazards.

- Q:What are the different types of steel pipe bends for pipeline routing?

- There are several different types of steel pipe bends commonly used for pipeline routing. These include 90-degree bends, 45-degree bends, and custom bends with specific angles as per the pipeline design requirements. Each type of bend serves a specific purpose in redirecting the flow of fluids or gases through the pipeline while maintaining structural integrity.

- Q:How are steel pipes used in railway infrastructure?

- Steel pipes are used in railway infrastructure for a variety of purposes. They are primarily used for constructing and maintaining railway tracks, as they serve as the support structure for the rails. Steel pipes are also used for the fabrication of various components such as bridges, signal systems, and overhead power lines. Additionally, steel pipes are utilized in the construction of tunnels, culverts, and drainage systems to ensure proper water management along the railway lines.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Spot 20# seamless steel tube high pressure seamless steel tube Q345B seamless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

- Option:

- 76*5 89*6 Other size please phone me 114*8 133*10 108*8

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords