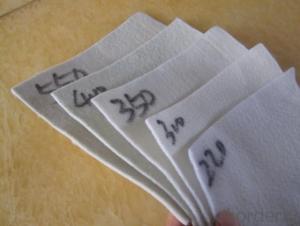

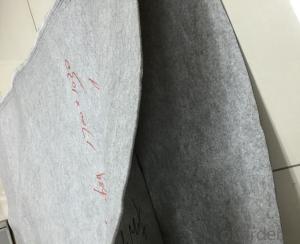

Non Woven Needle Punched Geotextile

Non Woven Needle Punched Geotextile Related Searches

Geomembrane In Road Construction Geotextile Mesh Perri Construction Non Woven Needle Punched Geotextile Non Gas Powered Generator Terram Geotextile Membrane Jute Geotextile Terram GeotextileHot Searches

Bidim Geotextile Price Geotextile Membrane Suppliers Non Woven Geotextile Fabric CostNon Woven Needle Punched Geotextile Supplier & Manufacturer from China

Okorder.com is a professional Non Woven Needle Punched Geotextile supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Non Woven Needle Punched Geotextile firm in China.Hot Products

FAQ

- Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Geotextiles help with reinforcement of geosynthetic tubes by providing additional strength and stability. They act as a barrier between the soil and the tube, preventing soil erosion and maintaining the shape and integrity of the tube. The geotextile fabric also helps distribute the load evenly across the tube, preventing localized stress and potential failure. Additionally, geotextiles can improve filtration and drainage, allowing water to pass through while retaining the soil particles, thus enhancing the overall performance and longevity of the geosynthetic tube.

- What are the geotechnical test test items for highway engineering? The

- The main inspection items are: ① Tensile strength: In the tensile test, the maximum tensile stress of the specimen up to the fracture is the tensile strength, which is called tensile strength in academia. ② elongation: elongation, that is, the percentage of the ratio of the total deformation to the length of the original gauge after the tensile fracture of the specimen. ③ tear strength: it is a thin film or thin film tear resistance of a test method defined in a term. This method is a tear test performed on a special testing machine with a specimen with a predetermined gap. ④ bursting strength ⑤ thickness ⑥ per unit area quality ⑦ permeability coefficient: permeability coefficient, also known as hydraulic conductivity. In an isotropic medium, it is defined as the unit flow rate per unit of hydraulic gradient, indicating the ease with which the fluid passes through the pore skeleton.

- Geotextiles typically have a lifespan of 20 to 25 years, depending on factors such as the type of material used, the level of exposure to environmental conditions, and the intensity of usage.

- Geotextiles provide an effective solution for pipeline protection by acting as a protective barrier between the pipeline and the surrounding soil. They prevent soil particles from infiltrating the pipeline, reducing the risk of corrosion, abrasion, and damage. Additionally, geotextiles can help distribute loads and provide stability, enhancing the overall structural integrity of the pipeline system.

- Geotextiles are used in construction to provide reinforcement, filtration, separation, and drainage functions in various applications such as road construction, erosion control, retaining walls, landfills, and drainage systems. They act as a barrier, preventing soil erosion, improving soil stability, and increasing the overall durability and performance of the construction project.

- Green belt with no cloth a film seepage geotextile cloth how

- The water will be missed, the general green belt does not require the use of two cloth a film, according to design requirements it