Short Fiber Needle Punched Non Woven Geotextile 1200g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geotextile, made from PP or PET, has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects.

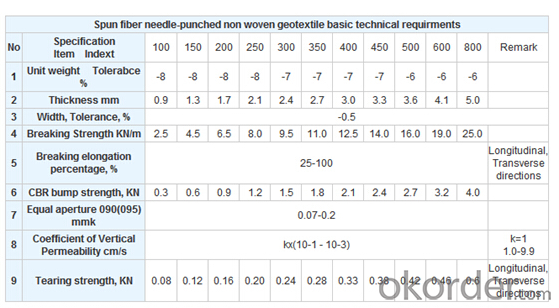

Product Specification

1. Weight: 100g~1500g

2. Width: 1m ~ 7m

Product Package:

Packing: Plastic film inside & Woven bag outside.

Shipping: About 15 days after receipt the deposit

Product Application

Product Application

Filtration

Separation

Adding

Protection

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geotextiles be used in geosynthetic clay liners?

- Yes, geotextiles can be used in geosynthetic clay liners. Geotextiles are often used as a component in geosynthetic clay liners to enhance their performance by providing separation and filtration functions. They help to prevent the migration of fine particles and offer additional reinforcement to the clay liner.

- Q:Above a geotextile one, that there is any acceptance of norms?

- Geotextile with the relevant national standard, I am specializing in the production of geotechnical materials

- Q:What are the different geotextile installation techniques in reinforcement?

- There are several geotextile installation techniques used in reinforcement, including direct placement, sandwich method, and wrap-around method. In direct placement, the geotextile is laid directly on the soil or subgrade and then covered with additional soil or aggregate. The sandwich method involves placing the geotextile between two layers of soil or aggregate, creating a reinforced layer. The wrap-around method involves wrapping the geotextile around a structure, such as a retaining wall or pipe, to provide additional support and stability. These installation techniques help improve the strength and performance of soil structures in various engineering applications.

- Q:Roof of the geotextile

- Garage, roof green Huazhi geotextile manufacturers, solutions

- Q:What are the different types of geotextile installation equipment?

- Some common types of geotextile installation equipment include geotextile rollers, geotextile stitchers, geotextile spreaders, geotextile staplers, and geotextile tensioners. These tools are used to efficiently and effectively install geotextiles in various applications such as erosion control, soil stabilization, and drainage systems.

- Q:How do geotextiles help with reinforcement of geogrid wall systems?

- Geotextiles help with the reinforcement of geogrid wall systems by providing additional strength and stability to the structure. They act as a separator between the soil layers and the geogrid, preventing soil migration and maintaining the integrity of the wall system. Geotextiles also distribute loads evenly across the geogrid, reducing the risk of localized failures and improving overall performance and durability of the reinforced wall.

- Q:How do geotextiles interact with other geosynthetic materials?

- Geotextiles interact with other geosynthetic materials by providing reinforcement, filtration, separation, and drainage functions. They can be used in combination with geogrids, geomembranes, geocells, and other geosynthetics to enhance the overall performance and effectiveness of geotechnical engineering projects.

- Q:Can geotextiles be used for erosion control in river channels?

- Yes, geotextiles can be used for erosion control in river channels. Geotextiles are permeable fabrics that are designed to stabilize soil and prevent erosion by providing structural support and enhancing filtration. They can be installed in river channels to control erosion by reinforcing the riverbanks, protecting against scouring, and promoting vegetation growth. Geotextiles can effectively reduce sediment transport and maintain the stability of river channels, making them a suitable option for erosion control in these environments.

- Q:Sponge city sunken green land in the drilling drainage jacket how to set the amount of geotextile

- Need plastic blind ditch, complete specifications, collar Xiang new materials for your answer

- Q:Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles are permeable fabrics that can be placed between different soil layers to prevent mixing and maintain their distinct properties. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This separation helps in enhancing the stability and performance of the soil layers, reducing the risk of settlement and maintaining the integrity of the construction project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Short Fiber Needle Punched Non Woven Geotextile 1200g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords