Filament Geotextile,Non Woven Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

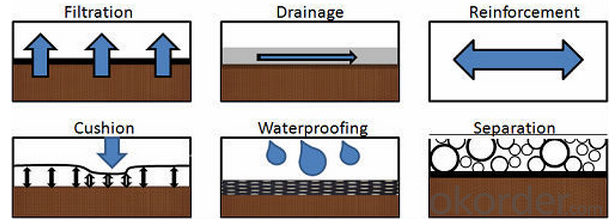

Filament Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drainage.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

Filament Geotextiles are available as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commonly used to separate layers like clay and drainage and to protect liner from damage.

Product Details

Features:

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction

Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

Excellent uniformity with high permeability and low pore size for soil filtration.

Supplied to a maximum width of 8.0 meters,ensuring minimum waste over large construction areas.

100% polypropylene or polyester staple fibers ,needle punched and random network formation.

UV and rot resistant and biological degradation resistant.

Majority Process:

Specific Data:

cItem | Area weight | Tensile Strength | Elongation | shrinkage | Roll Size | ||

MD | CMD | MD | CMD | ||||

Unit | G/M2 | N/125px | % | % | m x m | ||

Specification | 120 | ≥350 | ≥260 | 23 | 28 | <2.0< span=""> | 1.02x1700 |

140 | ≥380 | ≥300 | 25 | 30 | <1.0< span=""> | 1.01x1500 | |

150 | ≥500 | ≥330 | 28 | 35 | <1.0< span=""> | 1.01x1500 | |

160 | ≥550 | ≥350 | 30 | 35 | <1.0< span=""> | 1.01x1400 | |

180 | ≥600 | ≥450 | 30 | 35 | <1.0< span=""> | 1.01x1200 | |

200 | ≥750 | ≥450 | 30 | 35 | <1.0< span=""> | 1.01x1100 | |

220 | ≥800 | ≥500 | 30 | 35 | <1.0< span=""> | 1.01x1000 | |

250 | ≥950 | ≥600 | 35 | 40 | <1.0< span=""> | 1.01x800 | |

FAQ:

1. How to order your geotextile?

a). Tensile strength in warp & weft direction

b). gram per meter

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

3. Delivery time

a) 19-25 days after received your deposit .

4. What is MOQ ?

a) 2000 m2 as MOQ , we can also produce sample for you .

- Q:How is this set of water quotas? More

- Hello, I am specializing in the production of geotextiles and other geotextile materials,

- Q:Geotextile standard is broken how low?

- Geotextile of the top of the strong implementation of the national standard GB / T-2008, the standard of the geotextile bursting strength requirements in the international arena is not very low. Geotextile because it is produced by fiber acupuncture, and its breaking strength and elongation at break for the main performance indicators, even in practical applications when we are mainly using these two characteristics of geotextile. Breaking strength is called CBR bursting strength, the main test is the product of anti-puncture, the general waterproof, impermeable material requirements are higher, and geotextile is the filter, the protection of materials, so the standard requirements are lower.

- Q:Can geotextiles be used in the protection of retaining walls?

- Yes, geotextiles can be used in the protection of retaining walls. Geotextiles are often used as a filter or separation layer behind retaining walls to prevent the migration of fine soil particles and provide drainage. They help in distributing the load and reducing the pressure on the wall, increasing its stability and lifespan.

- Q:What are the different geotextile filtration testing methods?

- Some of the different geotextile filtration testing methods include the gradient ratio test, the permittivity test, the sieve analysis test, the flow rate test, and the hydraulic conductivity test. These methods are used to determine the effectiveness of geotextiles in filtering water and preventing soil erosion.

- Q:Can geotextiles be used in waste containment projects?

- Yes, geotextiles can be used in waste containment projects. Geotextiles are often used as a barrier or liner in landfills, waste ponds, and other waste containment systems to prevent the migration of pollutants into the environment. They provide filtration, separation, and reinforcement functions, making them a valuable component in waste containment projects.

- Q:What is the representative batch of geotextile?

- Geotextile batch is 2000 square meters.

- Q:What are the specifications for geotextiles in railway projects?

- The specifications for geotextiles in railway projects generally include requirements for strength, durability, permeability, and filtration. These geotextiles should have sufficient tensile strength to withstand the dynamic loads imposed by trains and maintain their integrity over time. They should also be resistant to degradation caused by UV exposure, chemical exposure, and biological factors. The permeability of geotextiles is crucial to ensure proper drainage and prevent water accumulation, which can lead to instability. Additionally, the geotextiles should possess excellent filtration properties to prevent the migration of fine particles and maintain the stability of the railway subgrade.

- Q:What are the uses of acupuncture geotextiles?

- Acupuncture geotextile is divided into filament spunbonded acupuncture non-woven geotextile and polyester staple acupuncture non-woven geotextile two. Filament spunbond acupuncture non-woven geotextile with high-quality polyester chips through high-temperature melting, spinning into a network, acupuncture into cloth production, filament spunbond acupuncture non-woven geotextile has a high tensile strength, Anti-tear strength, anti-breaking strength, in the project to play the role of reinforcement protection, generally used in roads, railways, dams, water conservancy construction, tunnels, landfills and other projects. Polyester staple acupuncture non-woven geotextile polyester staple fiber made by acupuncture, polyester staple acupuncture non-woven geotextile has a good water filter performance, the price is relatively low, in the project to play a reinforced protection, The role of filtration, generally used in civil engineering isolation, filtration, drainage sites.

- Q:Are geotextiles resistant to punctures and tears?

- Yes, geotextiles are generally designed to be resistant to punctures and tears. They are made from strong materials that provide durability and can withstand external forces, making them an effective solution for various applications requiring such resistance.

- Q:Whether the reservoir is geotextile or geomembrane is good

- Composite geomembrane and geomembrane can be. Detailed consultation to see the information

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Filament Geotextile,Non Woven Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords