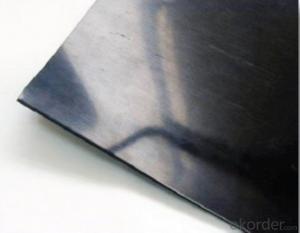

Geomembrana En Honduras

Geomembrana En Honduras Related Searches

Venta De Geomembrana En Mexico Venta De Geomembrana En Honduras Venta De Geomembrana En Puebla Geomembrana En Honduras Piscinas En GeomembranaHot Searches

Solar Wafer Manufacturers N Type Silicon WaferGeomembrana En Honduras Supplier & Manufacturer from China

Okorder.com is a professional Geomembrana En Honduras supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrana En Honduras firm in China.Hot Products

FAQ

- Geomembranes contribute to landfill design by providing a barrier between the waste materials and the environment, preventing the leakage of harmful substances into the soil and groundwater. They help in containment and control of leachate, methane gas, and odors, thus minimizing the environmental impact of the landfill. Additionally, geomembranes aid in the stabilization of landfill slopes, reducing the risk of slope failure and ensuring long-term sustainability of the landfill structure.

- HDPE geomembrane related

- HDPE geomembrane in the anti-seepage construction quality inspection method 1: laying anti-seepage membrane should be civil engineering corresponding to the corresponding acceptance of documents. 2: anti-seepage film before cutting, it should accurately measure the relevant size, and then according to the actual cutting, generally should not be cut according to the size of the figure, should be piece by piece number, detailed records in the special form. 3: laying impermeable membrane should try to weld at least, in ensuring the quality of the premise, as far as possible to save raw materials. But also easy to ensure quality. The lap width of the joint between the membrane and the membrane is generally not less than 10 cm, usually in the direction of the weld arrangement parallel to the maximum slope, that is, along the slope direction. 4: usually in the corner and the deformity of the lot should be shortened in length. In addition to the special requirements, in the slope of more than 1: 6 on the slope from the top of the slope or stress concentration area of 1.5 meters, as far as possible without weld.

- The considerations for geomembrane selection in power plant ash ponds include factors such as the type and composition of the ash, the chemical and physical properties of the surrounding soil and groundwater, the expected lifespan of the pond, and the potential for puncture, tear, or abrasion. Other important considerations include UV resistance, compatibility with the ash, installation and maintenance requirements, and regulatory compliance.

- Geomembranes are tested for seam strength through a variety of methods, including peel and shear tests. These tests involve applying a controlled force to the seam to evaluate its resistance to separation and deformation. Additionally, destructive tests such as burst tests are conducted to determine the maximum pressure the seam can withstand before failure. Non-destructive methods like ultrasonic testing and visual inspections are also used to detect any defects or weak spots in the seam.

- nan

- You can refer to professional standards of geomembrane applications. The main thing is to ensure that the geomembrane is not damaged during construction, refering to the engineer application standards of geosynthetics. Construction should have a scheme. Cusion layer on the film is generally completed by other civil construction teams. Generally the construction of geomembrane is conducted by the geomembrane manufacturer present market, especially the application standards of geosynthetics in water?conservancy?industry. Geomembrane is one of the geosynthetics, which is more professional in water?conservancy?industry. Because geomembrane is used for water-proofing and seepage-proofing.

- nan

- Clear substances that have hidden danger of puncture on bare base surface, completion and acceptance, etc. Acceptance of construction quality. ③Repair methods of damaged parts; welding form is double bead. 5. Recommendation 1, the maximum design water level. Ther is nooil pollution at joint. Planned duration is 3 days. Substances that can cause harm to anti-seepage film and constructors related to water proof materials. First, cut HDPE geomembrane into trumpet-shaped pipe sleeve according to the diameter of leachate in dam. 50×4m, do not wipe in hands. Bond is made up of asphalt latex paint, otherwise, set aside telescopic deformation caused by changes of temperature. ②Operating temperature of sweat soldering is 280 -300℃. ②Water resistance of bridge foundation. Weld after treatment. 4, Need latitudinal splicing so as not to damage the membrane surface. Dew: 5% to 8%.

- Geomembranes contribute to the preservation of coastal ecosystems by providing a protective barrier against erosion and preventing the contamination of water bodies. They help to stabilize the coastline by reducing wave energy and preventing sediment erosion, which in turn protects the delicate habitats and ecosystems along the coast. Additionally, geomembranes are used in the construction of artificial wetlands and other coastal restoration projects, creating suitable habitats for marine life and promoting biodiversity. Overall, geomembranes play a crucial role in safeguarding coastal ecosystems and ensuring their long-term preservation.

- The potential long-term effects of geomembrane use on the environment can include various factors. These may include changes in soil and water quality due to the accumulation of chemicals and pollutants in the geomembrane, alteration of natural drainage patterns leading to waterlogging or erosion, disruption of ecological balance by blocking natural habitats and migration routes of wildlife, and potential risks associated with the disposal and degradation of geomembrane materials. It is crucial to carefully monitor and manage the use of geomembranes to minimize any negative impacts on the environment.