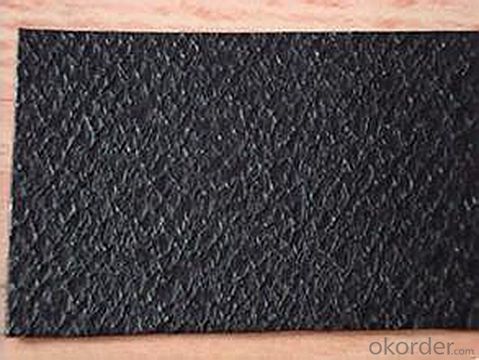

Polypropylene Smooth Waterproof Membrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geomembrane

Thickness: 1.0mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

Impermeable Geomembrane HDPE for Shrimp Pond is mainly made of virgin HDPE with blow molding technique. Its main function is to prevent the liquid leakage and gas volatilization.

Features:

1.It can effectively make the concentrated stress diffuse, transfer or decompound, and prevent the soil mass against the destruction of outside force.

2.It can prevent the mixture of sandstone, soil mass and concrete of upper and lower layers.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What are the features of film mulching door sheet?

- 1. eco-friendly, beautiful: It is made of quality timber and eco-friendly bonding rubber through multi processes, recombinated and moulded under high temperature and high pressure. The door sheet surface has various colors or moulded layer with natural wood grain. The formaldehyde emission and harmful heavy metal content of the product is lower than the national standard. 2 natural decorative effect: The surface of the molded three-dimensional door sheet and pocket have been moulded, paint-free, eco-friendly, waterproof, fire?retardant, wear and pollution resistant, colorful and with the effect of natural wood grain. It can meet the demand of most users for natural timber without cutting down primeval forest. 3. waterproof and moisture proof, sound insulating and flame retardant: Three-dimensional interior door panels and pocket have unparallel waterproof, sound insulating and fire retardant performances through perfect design, delicate processing and technical application. 4. reliable quality, prominent advantages: Three-dimensional strengthened interior door panel through special treatment, featured by no deformation, no cracking, no delaminating, wear resistant, moisture-proof, environmental friendly, fire retardant, sturdy?and?durable, avoids many problems of the traditional door such as no abrasion and stain resistance, easy to deform, crack, delaminate, combuste and mildew, and that the surface has to be processed through several times of brushing or spraying paint.

- Q:Can geomembranes be used in floating baffles for wastewater treatment?

- Yes, geomembranes can be used in floating baffles for wastewater treatment.

- Q:How to clean the computer keyboard film?

- This film better not to clean in plain boiled water. It is better to clean with alcohol. If the alcohol does not work. The quality of your film may not be good. You are suggested to buy a ney one in the computer store.

- Q:composite geo-membrane, two cloths and one membrane geomembrane 6 meters thick material how to use multiple sets of quotas

- 10 meters dam seepage-proof construction, 1000g composite membrane quotas are not accurate, depth 6 meters, each design Institute are not the same, two cloths one membrane composite membrane 800 grams per square meter is sufficient .

- Q:Where are geotextiles and geomembranes usually used?

- Geotextiles are usually used for filtration, maintenance (including road maintenance and railway maintenance), reinforcement of roadbeds, seepage control of tunnels, construction of landfills. Geomembranes are usually used in for seepage control of gangues, landfills, cesspits, oil tanks, etc. The composite geo-membranes are made from geotextiles and geomembranes. They are usually used for seepage control of water conservancy facilities, such as artificial lakes, reservoirs, canals, etc.

- Q:How no proceed glass film on non-glued electrostatic membrane?

- Non-glued electrostatic membrane has three layers, just like a mobile phone film.Firstly,tear apart the first layer, stick it on the glass and then tear apart the surface film. Keep the middle layer, or only two layers, and tear apart one of them and stick. Then done.

- Q:How to stick the stick membrane of mobile phone?

- To fully clean up the surface of the screen, and wash hands your hand with clean water( to remove the electrostatic), and tear the the (marked 1 face), one end of the stick screen mobile phone along the first edge alignment film, then slowly down film. Finally, tear to B membrane surface (a standard surface)!

- Q:What is the operating principle of the vacuum laminating machine?

- The laminating machine must be the plastic packaging machine. The working principle is to insert the materal (or paper) to be plastic coated into the special plastic package, put the material into the plastic packaging machine, melt and solidfy the adhesive of the plastic package by heating and pressing and exhaust the air at the same time. By then plastic packaging is completed.

- Q:What are the advantages of using geomembranes in canal lining?

- There are several advantages of using geomembranes in canal lining. Firstly, geomembranes provide an impermeable barrier that prevents water seepage, reducing water loss through the canal system. This is especially important in arid regions where water resources are scarce. Secondly, geomembranes offer increased durability and longevity compared to traditional canal lining materials. They are resistant to corrosion, punctures, and chemical degradation, ensuring a longer lifespan for the canal lining. Additionally, geomembranes are easy to install and maintain, requiring minimal labor and maintenance costs. They can be prefabricated to fit the specific dimensions of the canal, making installation quick and efficient. Moreover, geomembranes have a smooth surface that minimizes frictional resistance, allowing for more efficient water flow through the canal. This can improve the overall hydraulic efficiency of the irrigation system and reduce energy consumption. Lastly, using geomembranes in canal lining can also help in preventing soil erosion and contamination. They act as a barrier between the canal water and the surrounding soil, preventing the leaching of harmful chemicals or pollutants into the soil. Overall, the advantages of using geomembranes in canal lining include reduced water loss, increased durability, ease of installation and maintenance, improved hydraulic efficiency, and protection against soil erosion and contamination.

- Q:Concrete and reinforced concrete construction program

- 1. Basis of Preparation: Contracts, drawings, regulations, standards, quality assessment standards. 2. Project Overview (should be relevant and concrete before, indicate each part of the basic amount of concrete, ready-mixed concrete suppliers) 3. Quality 4. concrete mix design goals and auditing (1) concrete requirements for raw materials; (2) concrete mix requirements; (3) supply of concrete; (4) checking concrete pumping capacity; transport (5) concrete. 5. pouring concrete (1) construction preparation; (2) construction conditions; (3) pouring concrete; (4) column concrete pouring; (5) pouring concrete shear wall (6) pouring concrete slab; (7) Concrete stairs pouring; (8) structural column, pouring concrete ring beams; pouring belt (9) after concrete pouring. Which includes concrete admixtures requirements; requirements for setting time of concrete; concrete slump requirements; levels in different parts of the concrete, leaving in vertical construction joint position requirements; concrete construction joint requirements; concrete pump, pump tubing and pump position different parts of the concrete slab requirements wipe the surface;; requirements for concrete vibrators vibration tools and methods; fixed tube requires segregation of different strength grade concrete intersection of the concrete. 6. 7. The concrete block and conservation measures to ensure the quality of product protection 9. 8. safe and civilized construction

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polypropylene Smooth Waterproof Membrane Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords