Geomembrana 0.75 of New LDPE Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrana 0.75 of New LDPE Made in China

Description Of Geomembrana 0.75 of New LDPE Made in China

Geomembrane is a plastic Film Raincoat. Currently, the main raw materials of Waterproof Geomembrane are mainly Plastic polyvinyl chloride (PVC) and polyethylene (PE), Eva (ethylene / vinyl acetate Copolymer), also designed for Special use in applications of Tunnel (ECB Ethylene vinyl acetate Modified Asphalt mixture Geomembrane).

Main Features of Geomembrana 0.75 of New LDPE Made in China

molecular structure, Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane, linear low density polyethylene (LLDPE) geomembrane, high-density polyethylene (HDPE) geomembrane;Aside from colorless and transparent raw material, you can made it into the black, green, blue, yellow, etc by adding different color masterbatch., also made into geomembrane with the black front and the blue back or other 2 different colors as required by customers.

Applications of Geomembrana 0.75 of New LDPE Made in China

1.LDPE geomembrane is applicable to hydraulic engineering: such as seepage control, plugging, reinforcement for rivers, lakes and reservoirs and dams, drainage seepage control, vertical core wall, slope protection, etc.

2. LDPE geomembrane's applications in municipal engineering: subway, underground works of the building, planting roof, roof garden, sewage pipe seepage control;

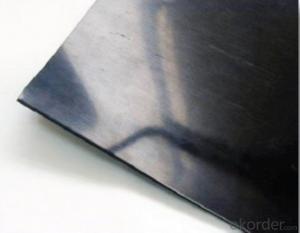

IMages of Geomembrana 0.75 of New LDPE Made in China

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:What is the construction technology of the color permeable concrete project?

- 1. To grind surface and use professional grinding machine polishing on the surface of the base, surface laitance, dust cleaning, open the original surface voids and make concrete seal curing agent could be fully penetrated 2, clean up the surface to be polished produced in the process of dust, the dust cleared off. 2. To clean up the surface: The dust produced in the process of polishing should be cleaned off. 3. To spray the concrete sealed curing agent and spray the concrete seal curing agent on the ground, and use the dust drag for uniform treatment. Let material response 2-4 hours. When the surface becomes sticky, you can go on the next step. 4. To clean the surface and water to flush the concrete seal curing agent material overflow part of the flushing reaction. To prevent the residue turn into white. 5. The water polishing. To polish the ground to further enhance the density of the ground surface, and show the mirror effect. 6. To clean the ponding, the remaining water should be cleaned after the water polishing. 7. The polishing of the concrete sealed curing agent, and install the resin polishing pad with the polishing machine, making a further polishing of the ground. 8. The completion display of the concrete seal curing agent .

- Q:What are the advantages of using geomembranes in roof waterproofing?

- There are several advantages to using geomembranes in roof waterproofing. Firstly, geomembranes are highly resistant to water and moisture, effectively preventing leaks and water damage. Secondly, they are also resistant to UV rays, which means they can withstand prolonged exposure to sunlight without deteriorating. Additionally, geomembranes are flexible and can be easily installed on roofs of different shapes and sizes. They also have a long lifespan and require minimal maintenance, making them a cost-effective solution for roof waterproofing. Finally, geomembranes are environmentally friendly as they are made from recyclable materials and do not release harmful chemicals into the environment.

- Q:Difference between cars and home insulation film

- Furniture glass insulation film is actually architectural glass insulation film, they are different specifically the following points: First, the car film and construction film can insualte the UV, but UV-absorbing layer film structure is not the same car has ultraviolet barrier layer

- Q:What is the role of the base film

- The role of the base film is cured to protect the wall, the wall is equivalent to stick a protective film which is a water-based environmentally friendly materials, tasteless, non-toxic, no side effects on the human body, and now the wallpaper has to be brushed before pasting.

- Q:What are the limitations of geomembranes in high-temperature environments?

- Geomembranes, although widely used for containment and environmental protection, have limitations in high-temperature environments. One major limitation is their susceptibility to thermal degradation and loss of mechanical properties when exposed to elevated temperatures. This can lead to reduced durability and integrity of the geomembrane, compromising its effectiveness as a barrier. Additionally, high temperatures can cause dimensional changes, such as expansion or contraction, which may further impact the geomembrane's performance. Therefore, careful consideration and selection of suitable materials with high-temperature resistance are crucial when using geomembranes in such environments.

- Q:Are geomembranes permeable to water?

- No, geomembranes are not permeable to water.

- Q:What are the maintenance requirements for geomembranes?

- The maintenance requirements for geomembranes typically involve regular inspections to check for any signs of damage or deterioration, as well as cleaning and removal of any debris or sediment that may accumulate on the surface. Additionally, it is important to address any potential issues promptly, such as repairing small tears or punctures, to prevent further damage or failure of the geomembrane.

- Q:Can geomembranes be used in decorative landscape designs?

- Yes, geomembranes can be used in decorative landscape designs. They can be used as liners for ponds or water features, as well as for retaining walls or raised garden beds. Geomembranes provide a barrier against water leakage and can help maintain the integrity and aesthetics of the landscape design.

- Q:Are geomembranes resistant to punctures from animal burrowing?

- Yes, geomembranes are generally resistant to punctures from animal burrowing. These synthetic liners are designed to provide a durable barrier against various environmental elements, including animal activities. The thickness and composition of geomembranes make them highly resistant to punctures, ensuring long-term protection for containment systems such as landfills, ponds, and reservoirs. However, it is important to consider the specific characteristics of the geomembrane and the type of animals present in the area to ensure proper installation and prevent any potential damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geomembrana 0.75 of New LDPE Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords