Geomembrana 0.5-2.5 mm of New HDPE Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrana 0.5-2.5 mm of New HDPE Made in China

Description Of Geomembrana 0.5-2.5 mm of New HDPE Made in China

Geomembrane is a plastic Film Raincoat. Currently, the main raw materials of Waterproof Geomembrane are mainly Plastic polyvinyl chloride (PVC) and polyethylene (PE), Eva (ethylene / vinyl acetate Copolymer), also designed for Special use in applications of Tunnel (ECB Ethylene vinyl acetate Modified Asphalt mixture Geomembrane).

Main Features of Geomembrana 0.5-2.5 mm of New HDPE Made in China

Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane

Applications of Geomembrana 0.5-2.5 mm of New HDPE Made in China

Low density polyethylene geomembrane for transport facilities: foundation reinforcement for the road, culvert seepage control

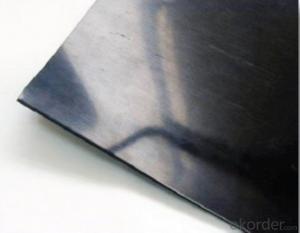

IMages of Geomembrana 0.5-2.5 mm of New HDPE Made in China

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:What are the uses of geogrids?

- Geogrids play a very important role in road construction, mainly used to reinforce roadbeds and extend life time of the roads. Following is a detailed introduction. 1. Geogrids are mainly used to reinforce soft grounds, roadbeds and abutments, to protect side slopes, in reinforced soil projects and other civil engineering applications including wing walls, retaining walls, etc. 2. Geogrids can protect the railway on soft grounds from settlement and damage. 3. Geogrids can be used in the water?conservancy engineerings including risk-removal and reinforcement of reservoirs, dams, canals and reclaiming?lands. 4. Geogrids in the bases of airports can improve the bearing capacity of the runways and ensure the safety. 5. Geogrids can also be used in other fields such as mining industry, metallurgy industry and civil engineering including landfills, power stations, ash dams, landscapes and fences. 6. Geogrids can be used to reinforce soft grounds and improve the bearing capacity of the bases.

- Q:Can geomembranes be used in reservoir liners?

- Yes, geomembranes can be used in reservoir liners. They are commonly employed to provide impermeable barriers that prevent water seepage and ensure the integrity of reservoirs.

- Q:Principle of energy saving insulation film?

- Building energy-saving insulation film through the application of new IR coating, we will be unable to reverse the IR absorption by reducing their access to the other side of the glass; the achievements of the most advanced technology energy-saving insulation film insulation, energy conservation, safety, anti-UV, anti-glare light improvement.

- Q:What is the material of the installation technology of soft membrane?

- It is made of special PVC materials without cadmium and the fire rating of B1. There is a very good fire performance.

- Q:Can geomembranes be used in green roof systems?

- Yes, geomembranes can be used in green roof systems. Geomembranes are impermeable materials that can help control water flow and prevent leaks in green roof systems. They can be used as liners or barriers to ensure proper water retention and prevent water damage to the underlying structures.

- Q:Are geomembranes suitable for use in hazardous waste containment?

- Yes, geomembranes are suitable for use in hazardous waste containment. They are impermeable barriers that can effectively prevent the migration of hazardous substances into the environment, ensuring the safe containment and management of such waste.

- Q:Are geomembranes resistant to punctures from construction equipment?

- Yes, geomembranes are typically designed to be resistant to punctures from construction equipment. They are engineered using durable materials and thicknesses that can withstand the potential impact and pressure exerted by such equipment. However, it is important to note that the resistance may vary depending on the specific type and quality of the geomembrane used.

- Q:What are the connection methods of geomembrane?

- Geomembrane connection and surrounding buildings connection self connection and surrounding buildings connection depending on building conditions or imbuilt or anchorage, see details in corresponding professional books geomembrane self connection mainly has two types: Hot pressing bonding bind with adhesive hot pressing bonding is now basically use professional welding machine to finish the assignment must use needle materials formulate operating procedures depending on specific circumstances testing in the same situation can use specific parameters according to site conditions select test and adjust actual line and adjust the welding machine parameters to finish the operation and to ensure that the seam welding quality adhesive bonding hot pressing bonding material using adhesive bonding effect is difficult to ensure try to select according to adhesive use instructions for operation Check the seams after geomembrane seam welding operation and inspection to meet the requirements of joint of remedial

- Q:Can geomembranes be used in dam construction projects?

- Yes, geomembranes can be used in dam construction projects. Geomembranes are impermeable liners made from synthetic materials such as HDPE, PVC, or EPDM, which are designed to prevent seepage of water or other liquids. They can be installed as part of the dam's lining system to enhance its impermeability and prevent water loss. Additionally, geomembranes can provide protection against erosion and help maintain the structural integrity of the dam.

- Q:What are the different thickness options for geomembranes?

- The thickness options for geomembranes typically range from 0.5mm to 3.0mm, depending on the specific application and requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geomembrana 0.5-2.5 mm of New HDPE Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords