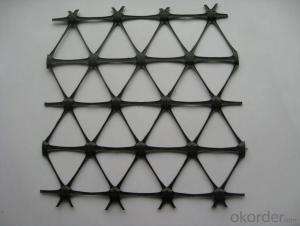

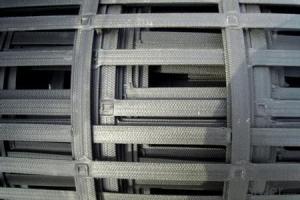

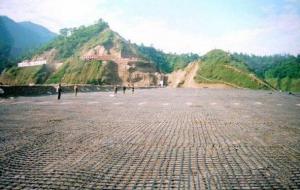

Geogrid Function

Geogrid Function Related Searches

Led For Cannabis Growing Fiberglass Sheets For Roofing Geogrid For Road Construction Geogrid For Erosion Control Geogrid For Soil Stabilization Geogrid For Horse Paddocks Geogrid For Gravel Geogrid For Pavers Geogrid For Steep Slopes Geogrid For DrivewaysHot Searches

Pedestal Fan With Water Spray Price Mini Inverter With Battery Online Shopping Induction Cooker Coil Price Cost Of Electrical Wire Per Foot Electrical Equipment Price List Next Induction Cooker Price Home Depot Electrical Wire Prices Buy Electrical Wire Online Electrical Cable Types Wholesale Electrical Parts House Electrical Wiring Types Electrical Equipment Company Petaluma Electrical Wholesalers Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For SaleGeogrid Function Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Function supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Function firm in China.Hot Products

FAQ

- What power tools are used in electric stone carving tools and engraving inscriptions?

- Electric carving machine for carving art equipment, including miniature electric carving machine, small electric engraving machine, the whole cast iron structure of small electric engraving machine, bed after aging treatment, eliminate stress by rolling stone nuts of double ball screw, ensure the operation precision, and has the characteristics of high rigidity, high precision, high efficiency, stable operation, no noise. Electric engraving machine is the wood, stone, MDF and other materials engraving operations, applicable to process production, toys, handicrafts industry, decoration and furniture industry, flooring, wall panels, building materials and other industries.

- In decorating power tools, can the cutter for cutting tiles be used for cutting boards and grooving on walls?

- The ceramic tile cutting machine cutting, cutting the same can replace the cut piece in the slot wall; after can be used for cutting wood and other wood things; if cutting discs, can cut metal material.

- Why should the power tools be powered off when the people leave?

- Mainly for the safety of production, to prevent accidents.

- What is the cause of the burning of electric motor tools?

- (1) the installation and maintenance of motor, mistakenly triangle motor winding connection with Y connection, or mistakenly Y connection with the triangle. (2) winding phase, inter turn short circuit or earthing lead to winding current increase and unbalanced three-phase current, which makes motor overheating. (3) pole group coil connecting each phase coil number of incorrect or uneven distribution, resulting in the no-load current of three-phase unbalance, and the current is too large; when the motor is running the three-phase current imbalance, noise and vibration, motor overheating. (4) the stator and rotor become friction heated. (5) the cage rotor of induction motor is broken or the winding rotor winding is broken. The motor output is insufficient and overheated. (6) motor bearing overheating.

- How are carbon brushes made of power tools made?

- Carbon brush (Carbon brush), also known as brush, as a sliding contact, in many electrical equipment has been widely used. Carbon brushes are mainly used in products such as graphite, impregnated graphite, and metal (including copper, silver) graphite. The carbon brush is the energy transfer device or signal between motor or generator or other rotating machinery of the fixed part and the rotating part, it is generally made of pure carbon coagulant, the general shape is square, stuck in the metal bracket, which has spring pressed it on the shaft, when the rotation of the motor, the power through the change which is delivered to the coil, as its main components are carbon, known as carbon brush, it is easy to wear. Regular replacement, cleaning and carbon deposition shall be maintained.

- What's the function of the capacitor in the power tools?

- You don't ask very clearly, I think you ask the capacitor is the starting capacitorAC electric tools to turn up, you need a rotating magnetic field, while the individual current single-phase motor can not form the rotating magnetic field, so the need for a starting capacitor to phase to phase current, the two winding of the generated nearly 90 Eve joy difference, to produce a rotating magnetic field. Household fans, for example

- Can I bring power tools for the subway?

- It is prohibited to carry long (1.8 meters) and heavy (such as bicycles, washing machine, TV, desktop computer monitors, refrigerators, etc., and the combined sound) animal prejudice to public health, car traffic and passenger safety hazards (such as glass and glass products and other fragile articles).

- Which brand of power tools is good?

- Electric tools are mainly divided into imported brands and domestic brands, imported is Makita Hirose Hitachi Black & DeckerChina is rich, the big east into, good rest, some small brands of good quality and low price have no high school, see the consumer demand