Fiberglass Geogrid for Drainage Geocomposite

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid for Drainage Geocomposite

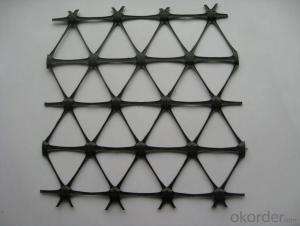

Description Of Fiberglass Geogrid for Drainage Geocomposite:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid for Drainage Geocomposite:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid for Drainage Geocomposite:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid for Drainage Geocomposite:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

IMages of Fiberglass Geogrid for Drainage Geocomposite:

FAQ of Fiberglass Geogrid for Drainage Geocomposite:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:How do geogrids improve the performance of reinforced slopes?

- Geogrids improve the performance of reinforced slopes by providing additional stability and strength to the soil structure. They act as a reinforcement material, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids also distribute the applied loads more evenly, reducing the potential for deformation and settlement. Overall, geogrids enhance the slope's resistance to erosion, improve slope stability, and increase the longevity and durability of the reinforced structure.

- Q:How do geogrids improve the performance of reinforced soil retaining walls?

- Geogrids improve the performance of reinforced soil retaining walls by providing additional tensile strength and stability to the structure. They enhance the soil's ability to resist lateral pressures and improve overall load distribution, which ultimately increases the wall's bearing capacity and structural integrity. Additionally, geogrids help prevent soil erosion and displacement, ensuring long-term stability and durability of the retaining wall system.

- Q:How long do geogrids typically last?

- Geogrids typically have a lifespan of 20 to 50 years, depending on factors such as installation quality, environmental conditions, and the specific application they are used for.

- Q:How is the installation of geogrids carried out?

- The installation of geogrids typically involves preparing the subgrade by removing any loose soil or debris, compacting the surface, and then laying the geogrid on top. The geogrid is then secured in place using stakes or anchors, and additional layers of soil or aggregate are placed on top to cover the geogrid. This helps to reinforce the soil, increase its stability, and prevent erosion or soil movement.

- Q:Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are engineered materials that provide reinforcement and stability to soil. They are designed to improve the performance of soil structures in various conditions, including seismic events. Geogrids can help increase the tensile strength and stability of soils, reducing the risk of soil liquefaction and enhancing the overall resilience of structures in seismic zones.

- Q:What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q:Geogrid price? Solution!

- Geogrid effect1 used for roadbed reinforcement, so that the granular filler and mesh together locked together to form a stable plane, to prevent the collapse of the filler, and the vertical load can be dispersed, the geographical conditions of poor areas can be used multi-layer reinforcement;2 in the embankment and embankment fill can increase its stability, reduce the area;

- Q:EG65R type geogrid meaningWhat is the meaning of EG, said 65 per meter of tensile strength is 65kN? 65KN/m R will be broken? What is the meaning?

- Is that tension can reach more than 65KN, as can pull off in what, I do not know, if there is a need to contact me, thank you, hope to adopt!

- Q:The difference between geocell and geogrid

- The geocell is a kind of three-dimensional grid chamber structure, which is formed by the high strength welding of the HDPE material. Generally welded by ultrasonic needle. Due to the need of the project, some of them are punched on the diaphragm.

- Q:Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering projects to improve soil stability and prevent soil erosion. They are effective in providing reinforcement and reducing the potential for soil settlement, making them suitable for enhancing the stability of pipelines in various soil conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid for Drainage Geocomposite

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords