High Tensile Geogrid Plastic Geogrid with Factory supply

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

1. Prevent road collapse and crack

2. Prevent soil and water loss in slope

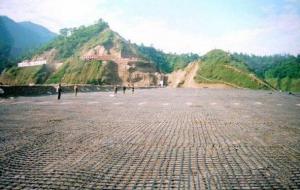

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Geogrid Show:

- Q:What is the recommended overlap for geogrid installation?

- The recommended overlap for geogrid installation typically varies depending on the specific project and geogrid manufacturer's recommendations. However, in most cases, a minimum overlap of 1-2 feet (30-60 centimeters) is recommended to ensure proper connection and load distribution between adjacent geogrid panels.

- Q:Can geogrids be used in slope stabilization for railway embankments in permafrost regions?

- Yes, geogrids can be used in slope stabilization for railway embankments in permafrost regions. Geogrids provide reinforcement and stabilization to the soil, reducing the risk of slope failure and ensuring the stability of the embankment. They are particularly effective in permafrost regions where the frozen ground can be prone to thawing and subsidence. Geogrids improve the overall strength of the embankment, minimize soil movement, and help to maintain the integrity of the railway infrastructure in these challenging environments.

- Q:How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing stability to soil and reducing the need for excessive excavation and material usage. They allow for the use of locally available and low-quality soil, eliminating the need to import expensive and environmentally damaging materials. This reduces the amount of waste generated during construction and helps in preserving natural resources.

- Q:Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q:Construction technology of steel plastic grille

- (6) in the third layer (coarse sand) after rolling, along the line in the longitudinal slope on both sides of the geogrid two, overlapping 0.16m, and connected with the same method, and then start the earthwork construction work, laying geogrid in slope protection, each layer must measure the laying of lines, each side to ensure the slope renovation of geogrid buried in slope soil 0.10m.(7) when the geogrid is filled with two layers of soil, that is to say, the thickness of 0.8m is required to lay a layer of geogrid at the same time on both sides, and so on.(8) the Subgrade after timely slope renovation, and dry rubble slope protection, in addition to each side of the roadbed widening 0.3m, and set aside 1.5% of the settlement.

- Q:Can geogrids be used in underground mining applications?

- Yes, geogrids can be used in underground mining applications. Geogrids are commonly used for reinforcement and stabilization purposes in mining operations, specifically in the construction of underground tunnels, shafts, and walls. They provide support to the surrounding soil or rock, enhance stability, and help prevent deformation and collapse. Geogrids are particularly useful in underground mining environments as they are resistant to chemical and biological degradation, have high tensile strength, and can withstand heavy loads.

- Q:What are the factors that affect the long-term creep behavior of geogrids?

- The factors that affect the long-term creep behavior of geogrids include the type and quality of the geogrid material, the magnitude and duration of the applied load, the temperature and moisture conditions, the stiffness of the surrounding soil, and the installation and construction techniques.

- Q:Are geogrids effective in preventing soil erosion around pipelines?

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids provide stability and reinforcement to the soil, preventing it from eroding and protecting the pipelines from potential damage.

- Q:History of geotechnical materials

- Geosynthetics are widely used in geotechnical engineering at present, which is a general name of polymer products. As early as in 1920s, the chemical industry was successful in the production of synthetic materials, but it was not until the late 50s that the material was gradually used as a new type of building materials to be used in geotechnical engineering. In the early stage, the products were mainly pervious to spinning and non-woven geotextiles, and later produced impermeable geomembrane. With the requirement of engineering practice and the improvement of manufacturing technology, the geogrid and other composite products with high strength reinforcement are manufactured. In this way, the original geotechnical fabric word has not summarized all kinds of products in the international meaning, so there are many alternative names, the geotextile material was the most common, but the habit still referred to as geotextile. Geotechnical material is divided into several categories of materials: geotextile, geomembrane, geogrid, drainage board, composite geomembrane, geotextile, geocell, bentonite waterproof blanket, etc..

- Q:Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge abutments on collapsible soils. Geogrids are commonly used in such applications to enhance the stability and load-bearing capacity of the soil, preventing lateral movement and potential collapse. The geogrids provide additional tensile strength and distribute the loads more efficiently, ensuring the long-term stability and durability of the bridge abutments on collapsible soils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Tensile Geogrid Plastic Geogrid with Factory supply

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords