Fry Reglet Corner Trim

Fry Reglet Corner Trim Related Searches

Stainless Steel Tile Trim Stainless Steel Trim Molding Stainless Steel Trim Strips Alside Pvc Aluminum Trim Coil Best Aluminum Trim Coil Aluminum Trim Coil White Black Aluminum Trim Coil Poly Aluminum Trim Coil Hunter Green Aluminum Trim Coil 24 X 50' Aluminum Trim CoilHot Searches

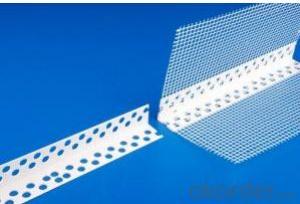

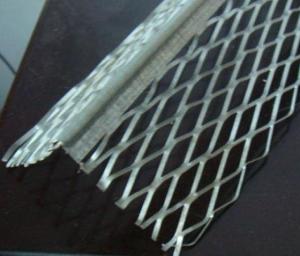

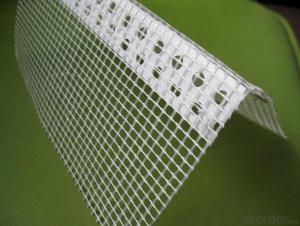

Aluminum Trim Coil Manufacturers Aluminum Trim Coil Suppliers Aluminum Trim Coil Near Me Wood Trim Suppliers Drywall Corner Bead Types Aluminum Trim Coil Manufacturers Aluminum Trim Coil Suppliers Aluminum Trim Coil Near Me Wood Trim SuppliersFry Reglet Corner Trim Supplier & Manufacturer from China

Okorder.com is a professional Fry Reglet Corner Trim supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Fry Reglet Corner Trim firm in China.Hot Products

FAQ

- What kind of rubber coated aluminum alloy (metal) better

- White Silicone, or at cyanide rubber, you have to brush the surface of metal binder, general is muruk we do, rubber products, these things often encounter

- Excuse me, what is in the rubber rubber, glue them, what is the difference?

- The toughness greatly improved than rubber glue. If the car tire is cooked. Generally the same thickness, soft as glue.

- What is the lowest cost material for the synthesis of rubber?

- Poly propylene rubber is synthetic materials, he is a kind of synthetic rubber, with ethylene propylene copolymer rubber basic monomer, divided into two EPDM (EPM) and three EPDM (EPDM) two categories;

- What about rubber molding, foaming and layering?

- Return the glue (the rubber has not been used up after heat treatmentThe glue and the new rubber are mixed together to heat up, and the remaining glue is called a return glue. When the mixture is mixed with the new rubber, the mixture is uneven and the degree of vulcanization is not uniform, resulting in delamination

- What is the size of the scorch time of the rubber?

- Rubber scorch characteristics usually use 120 degrees Mooney scorch time Ts said, also available vulcameter determining curing curve on the T10 or TA1, TA2 said, the scorch time and process, the rubber accelerator process conditions, the hardness of the rubber material and rubber material return use and other factors. Generally soft rubber is 10-20min; most of the stock (excluding high filling hard or high temperature 35-80min) is 20-35min; the high filling hard material is.

- How are rubber wires processed?

- Rubber wire, mainly refers to the insulating layer and the jacket is made of natural rubber, styrene butadiene rubber, ethylene propylene rubber, in addition to meet the insulation properties and physical mechanical properties, aging resistance, abrasion resistance requirements, some products require oil resistant, flame retardant.

- What solvent is used to clear the melted rubber layer?

- Dry glue in water does not exceed 1%, in the process can be volatile, but the moisture content is too long, will not only make the rubber easy to mildew during storage, but also the impact of rubber processing, such as mixing with the agent is easy to agglomerate; easy to blister calendering and extrusion process, the bubble or a sponge the curing process etc..

- Is the odour emitted by industrial rubber poisonous?

- In order to make all the necessary coordination agent in rubber, rubber Plasticating must first go through improving the plastic; then by mixing carbon black and all kinds of rubber and rubber additives are evenly mixed into rubber;