PVC PU Conveyor Belt High Tensile PVC flat Conveyor belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC PU Conveyor Belt High Tensile PVC flat Conveyor belt

Description:

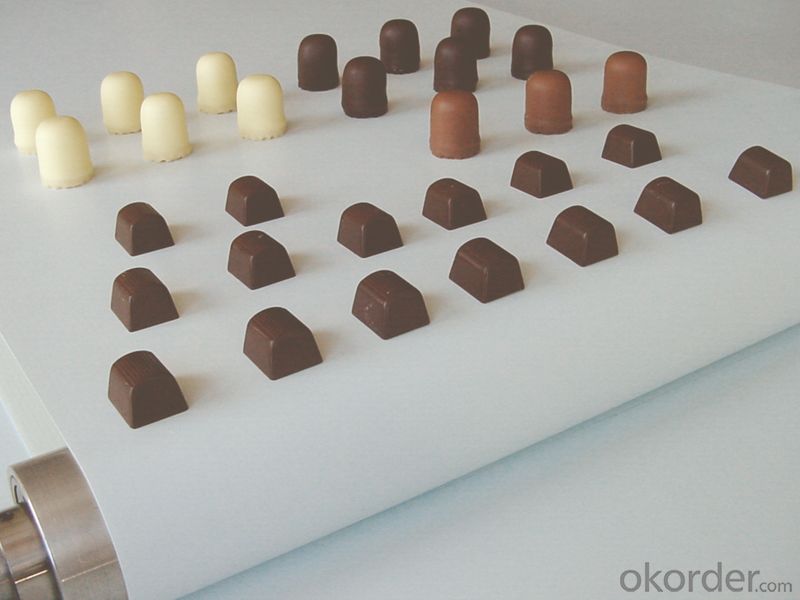

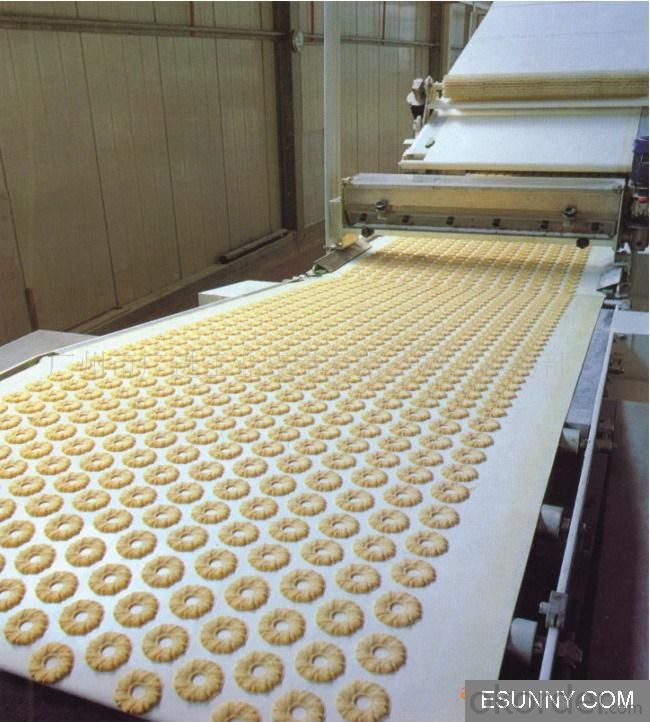

The PVC conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant. Our food conveyor belts are FDA/USDA approved and most types also have USDA Dairy Approvedand support your HACCP concept.

Features:

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

Applications

PVC Conveyor belt has a wide range of products which can be applied in different industries, such as: tobacco, food, logistics, post, airport machinery, phamaceuticals, chemistry, electronics, printing, cable pulling, steel wrapping and sports entertainment.

| Specification | Thickness (mm) | Color | Style |

| 1 ply fabric~1 ply p | 1 | green/white | plain |

| 1 ply fabric~2 ply p | 2/3/4/5 | green/white | skirt lace |

| 2 ply fabric~2 ply p | 2/3 | white/B.matt/green | diamond with small dot/grass |

| 2 ply fabric~3 ply p | 3 | green | diamond |

| 3 ply fabric~3 ply p | 4/5/6/7 | white/green matt | network wire |

| 3 ply fabric~4 ply p | 4/5 | green | diamond |

| 4 ply fabric~4 ply p | 9 | green matt | marble |

Above the form just list a part, we can product as your requirement, welcome to negotiate.

Pls contact me freely if any inquiry,thank you!

- Q:How can I make rubber products brighter?

- Special release agent for rubber products, release agent.Mold release agent is an interface coating used on two surfaces that are easy to adhere to each other. It can make the surface of the material easy to break off, smooth and clean. Mold release agent is used in various molding processes, such as glass fiber reinforced plastics, metal die casting, polyurethane foam and elastomer, injection molding thermoplastic, vacuum foaming sheet and extrusion section. In molding, sometimes other plastics, such as plasticizers, leak to the interface, and then a surface remover is needed to remove it.

- Q:How can I remove the rubber flavor on rubber products? It smells terrible

- This odor is stubborn, more difficult to solve in a short timeThe peculiar smell of a small rubber component in my car used for a week before cleaning it. If the price is not high, I suggest you change it.

- Q:There is a crack in rubber products

- I personally think and vacuum should be given no relationship, if it is the bubble, and vacuum will have relationship

- Q:Explain why butyl rubber is more resistant to oxidation and aging than other elastomers, such as natural rubber

- Ding Ji rubber (abbreviation: IIR English Name: Isobutylene-isoprene Rubber)Ding Ji rubber is an elastomer made from a small amount of isoprene (butadiene) copolymerized with isobutene with a high degree of saturation. Generally do not need refined refining, pay attention not toBlends with unsaturated rubber with low degree of unsaturation. Use super accelerators and less sulfur or cure with resin. Due to the slow vulcanization rate of ordinary butyl rubber and high unsaturated rubberIts poor compatibility, self adhesion and co adhesion were not good, and then it was modified by halogenation, which improved its curing rate and compatibility with other high unsaturated rubber

- Q:High strength rubber repairing agent

- The operation time, generally require the hole position Polish cleaning after the rubber putty filled in the damaged parts, and then use the scraper scraping smooth, repair parts and guarantee the smoothness can be part of the belt.

- Q:How do rubber undergo vulcanization?

- Heat vulcanization can be divided into three methods: direct vulcanization, indirect vulcanization and mixed gas vulcanization. Direct vulcanization; vulcanizing in hot water or steam medium. Indirect vulcanization, vulcanization in hot air. Third, gas vulcanization, first vulcanization with air, and then direct steam vulcanization.

- Q:How to improve the aging resistance of rubber?

- Whether it is rubber, rubber or rubber particles have a certain life, want to extend the service life of rubber and related products, we must first understand what factors affect the aging speed of rubber products, the four main factors affecting the aging of rubber particles for oxygen, ozone, heat and light.Oxygen oxidation by the rubber molecules of free radical chain reaction, molecular chain fracture or excessive crosslinking, cause the rubber properties changes.

- Q:PVC conveyor belts and rubber belts differ from each other in their respective advantages

- VC conveyor belt, good elasticity, not easy to deformation. Use high strength, high-quality cotton, nylon, polyester canvas as the core, with pure natural rubber pollution-free mixture, made white or light colored, pollution-free, does not affect the food hygiene, odor overlay. PVC belt product formula design is reasonable, accord with the hygiene index, the color is moderate, light and durable. PVC conveyor belt for the food industry or transport of bulk food department, canned and packaged food or food to large size 400, transport capacity from 1 cubic meters / hour to 6000 cubic meters / hour to.

- Q:Does the fuel pipe for automobiles belong to rubber products?

- First of all, make sure that your car is gasoline or diesel, and what parts to follow.

- Q:How to distinguish between silicone hose and rubber tube by appearance?

- Smell, silicone no flavor, rubber flavor, silicone general flexibility better, rubber mechanical better

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC PU Conveyor Belt High Tensile PVC flat Conveyor belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords