Steel-Frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

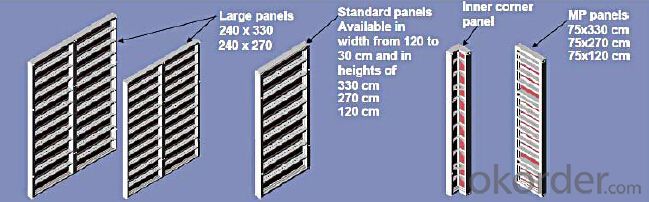

◆ The selection of panels.

◆ Kinds of panel connectors.

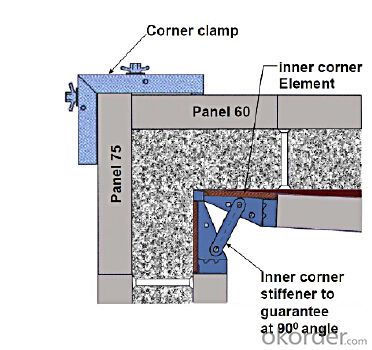

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:Can steel formwork be used for underground construction projects?

- Underground construction projects can indeed utilize steel formwork. Steel formwork proves to be a versatile and enduring option for erecting different types of structures, even those situated below ground level. It offers a robust and firm support system capable of withstanding the pressures and loads associated with underground construction. When it comes to constructing underground projects like tunnels, basements, or subways, steel formwork presents several advantages. Firstly, it boasts a high load-bearing capacity and structural integrity, making it suitable for enduring the weight and pressure exerted by the surrounding soil or water. This ensures the safety and stability of the structure being erected. Furthermore, steel formwork exhibits resistance to corrosion, a crucial attribute in underground construction where exposure to water, humidity, and other corrosive elements is prevalent. This corrosion resistance guarantees the longevity and durability of the formwork, minimizing maintenance needs and extending the lifespan of the structure. Moreover, steel formwork offers design flexibility and can be easily tailored to meet specific project requirements. It can be fabricated into various shapes and sizes, enabling the construction of intricate underground structures. The modular nature of steel formwork also facilitates effortless assembly, disassembly, and reusability, proving advantageous for projects that necessitate frequent formwork repositioning. In conclusion, steel formwork proves to be a suitable choice for underground construction projects due to its strength, durability, corrosion resistance, and design flexibility. It provides a dependable and efficient solution for erecting underground structures, ensuring their safety and longevity.

- Q:How long does it take to set up steel formwork?

- The time required to set up steel formwork can vary depending on the complexity of the project, the size of the structure, the experience of the workers, and the availability of resources. However, typically it can take a few hours to a few days to set up steel formwork for a construction project.

- Q:What are the different types of scaffolding used with steel formwork?

- Steel formwork can be used with various types of scaffolding, each having its own unique features and advantages. 1. Tube and Coupler Scaffolding is widely utilized with steel formwork. It comprises vertical tubes connected by couplers, enabling easy adjustment and flexibility in terms of height and width. It is renowned for its strength and stability, making it suitable for heavy-duty construction projects. 2. H-frame Scaffolding, similar to the tube and coupler system, employs H-shaped frames instead of vertical tubes. It is lightweight and easily assembled and disassembled, making it ideal for small-scale construction projects or areas with limited space. 3. Cuplock Scaffolding is a modular system that utilizes pre-fabricated components, including vertical standards with cup joints and horizontal ledgers. Its quick assembly and disassembly make it a popular choice for time-sensitive projects. Additionally, it is known for its versatility, as it can be used for both straight and curved structures. 4. Ringlock Scaffolding, like cuplock scaffolding, uses a rosette joint system instead of cups. This allows for greater flexibility in assembling and adjusting the scaffolding. With its durability and high load-bearing capacity, ringlock scaffolding is suitable for heavy construction projects. 5. Kwikstage Scaffolding is another modular system that employs pre-fabricated components, including standards, ledgers, and transoms. It offers excellent flexibility in terms of height and width adjustments and can be quickly assembled and dismantled. Kwikstage scaffolding is commonly used in construction projects requiring frequent movement and repositioning of scaffolding. In conclusion, the choice of scaffolding for steel formwork depends on specific project requirements, such as load-bearing capacity, flexibility, ease of assembly, and durability.

- Q:What are the different types of supports used in steel formwork construction?

- Steel formwork construction commonly utilizes various types of supports to provide stability and structural integrity to the formwork system, enabling it to withstand the weight of the concrete during pouring and curing. Among the frequently employed supports in steel formwork construction, the adjustable steel prop stands as one of the most prevalent. Consisting of adjustable steel tubes, these props can be extended or retracted to attain the desired height. They are primarily employed to uphold horizontal beams or slabs, with the flexibility to accommodate different heights and angles. Another support system found in steel formwork construction is scaffolding. Comprising metal frames and platforms, scaffolding is erected to create a temporary structure that allows workers to access the formwork. This is especially useful for larger construction projects involving multiple levels of formwork. Moreover, steel beams and columns can also serve as supports in steel formwork construction. These sturdy structural elements are designed to withstand heavy loads and provide stability to the formwork system. Typically, they are used in conjunction with other types of supports to establish a robust and secure formwork structure. In certain instances, hydraulic jacks may be utilized as supports in steel formwork construction. These jacks offer additional support to maintain the stability of the formwork system during the pouring and curing process. Ultimately, the choice of supports in steel formwork construction is contingent upon specific project requirements, including the size and weight of the formwork, the height and angle of the structure, and the availability of equipment and resources. It is imperative to carefully consider these factors and select the appropriate supports to ensure the safety and efficiency of the construction process.

- Q:How does steel formwork handle concrete curing?

- Steel formwork is widely chosen for concrete construction because of its durability and strength. When it comes to concrete curing, steel formwork offers several advantages. First and foremost, steel formwork ensures excellent support and stability for the concrete during the curing process. With its rigid structure, it guarantees that the concrete maintains its desired shape and form, preventing any deformations or bulges. This is especially important for projects that require precise dimensions or intricate designs. Secondly, steel formwork has good heat conductivity, enabling efficient heat dissipation during concrete curing. This is beneficial as it helps regulate the concrete's temperature, preventing excessive heat buildup that could result in cracks or other structural issues. Steel's ability to dissipate heat quickly also accelerates the curing process, reducing the overall time required for the concrete to achieve its desired strength. Moreover, steel formwork can withstand the high pressures exerted by the wet concrete during the curing phase. Its robust nature ensures that it remains intact and doesn't deform or buckle under the weight of the concrete, maintaining its structural integrity throughout the process. Additionally, steel formwork is reusable, making it a cost-effective option for concrete curing. Once the concrete has cured and hardened adequately, the formwork can be easily removed, cleaned, and reused for future projects. This eliminates the need for frequent formwork replacements and reduces construction waste. In conclusion, steel formwork is an ideal choice for concrete curing due to its stability, heat conductivity, strength, and reusability. It provides excellent support, regulates temperature, withstands high pressures, and offers cost savings. These characteristics make steel formwork a reliable and efficient option for ensuring successful concrete curing in construction projects.

- Q:Can steel formwork be used for both horizontal and vertical concrete placements?

- Yes, steel formwork can be used for both horizontal and vertical concrete placements. Steel formwork provides a durable and rigid structure, making it suitable for various types of concrete placements. Its strength and stability allow it to withstand the pressure exerted by the wet concrete, ensuring that it maintains its shape and form during the curing process. Steel formwork is versatile and can be easily adjusted and assembled to meet the specific requirements of both horizontal and vertical concrete placements. Whether it is for constructing slabs, walls, columns, or beams, steel formwork provides a reliable and efficient solution for creating quality concrete structures.

- Q:Can steel formwork be used for both horizontal and vertical applications?

- Yes, steel formwork can be used for both horizontal and vertical applications. Steel formwork is highly durable and can withstand high pressure and heavy loads, making it suitable for various construction projects. It can be used for horizontal applications such as floor slabs, beams, and foundations, as well as vertical applications like columns and walls. Steel formwork offers flexibility in design and can be easily assembled and disassembled, making it a preferred choice for construction projects that require repetitive use. Overall, steel formwork is a versatile option that can be utilized for both horizontal and vertical applications in construction.

- Q:How does steel formwork contribute to the overall durability of a structure?

- Steel formwork contributes to the overall durability of a structure in several ways. Firstly, steel formwork is highly resistant to wear and tear, which ensures that it can withstand the heavy loads and pressures exerted during the construction process. This durability prevents any deformations or damages to the formwork, ensuring that the structure is constructed accurately and without any compromise in its integrity. Additionally, steel formwork provides excellent dimensional stability, meaning that it retains its shape and size even under extreme conditions such as high temperatures or moisture exposure. This stability ensures that the concrete poured into the formwork maintains its desired shape and structural strength, resulting in a more durable and long-lasting structure. Furthermore, steel formwork offers superior strength and rigidity compared to other types of formwork materials. This strength enables it to support heavy concrete loads without any deformation or collapse, ensuring that the structure remains stable and secure. This characteristic is particularly important in the construction of large-scale structures such as bridges, high-rise buildings, or dams, where the formwork needs to bear significant loads for prolonged periods. Moreover, steel formwork is highly resistant to corrosion, which is a common cause of deterioration in construction materials. This resistance ensures that the formwork remains intact and unaffected by environmental factors such as moisture, chemicals, or exposure to the elements. As a result, the structure's overall durability is enhanced as the risk of corrosion-related damages is minimized. Lastly, steel formwork is reusable, which not only contributes to the sustainability of the construction process but also ensures cost-effectiveness. The ability to reuse the formwork multiple times reduces the need for additional materials and resources, resulting in less waste generation and lower construction costs. This factor also ensures that the formwork remains in good condition, as it can be properly maintained and inspected before each reuse, further enhancing its durability and longevity. In conclusion, steel formwork plays a crucial role in enhancing the overall durability of a structure. Its resistance to wear and tear, dimensional stability, strength, corrosion resistance, and reusability contribute to the construction of a robust and long-lasting structure, ensuring its integrity and minimizing the risk of structural failures or damages over time.

- Q:How does steel formwork contribute to the construction process?

- Steel formwork contributes to the construction process by providing a durable and reusable framework for concrete pouring. It ensures accurate shaping and alignment of the structure, allowing for efficient construction and reduced labor costs. Additionally, steel formwork offers increased strength and stability, enabling the creation of complex and high-rise structures with precision.

- Q:Can steel formwork be used in extreme weather conditions?

- Indeed, extreme weather conditions pose no challenge for the utilization of steel formwork. Steel, being an enduring and robust substance, can endure and withstand the harshest weather conditions, including scorching heat, freezing cold, heavy rain, and strong winds. Unlike wood or plywood, steel formwork remains impervious to moisture and temperature fluctuations, thus rendering it perfectly suitable for deployment in extreme weather conditions. Furthermore, steel formwork guarantees superior stability and structural resilience, thereby ensuring the safety and steadfastness of the construction project, even amidst adverse weather conditions. Nevertheless, it is crucial to bear in mind the necessity of adequately safeguarding and maintaining steel formwork to prevent corrosion or damage that may arise over time due to exposure to extreme weather conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-Frame Formwork for corner link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords