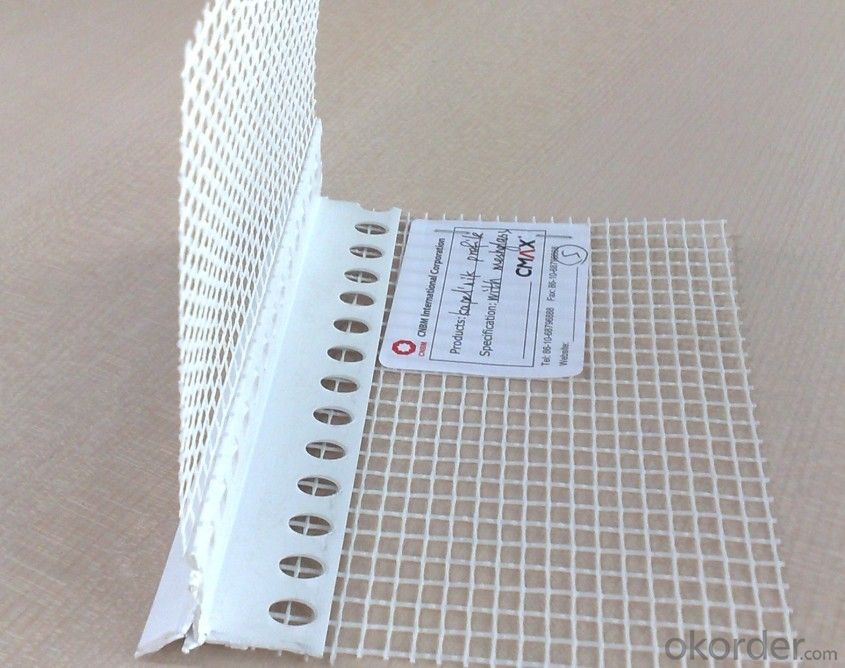

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

MOQ of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 : 5000 Square Meters

Supply Ability of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2: 6000000 Square Meters per Month

Payment Terms of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2: L/C,T/T

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

Specifications of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Place of Origin: China (Mainland)

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Application: Wall Materials

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Width: 1M-2M

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Size: 5*5/ INCH

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Weight: 40gsm to 200gsm

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Weave Type: Plain Woven

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Yarn Type: C-Glass

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Alkali Content: Medium

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 Standing Temperature: 500℃

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

Product information of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

Name: Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

Use best fiberglass yarn and best glue

Clear and beautiful Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

High strength Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

30 years experience of manufacturing Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

Excellent Priced

FAQ of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

Q: What is Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2?

Coated Alkali-resistant Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2 based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2?

Weight: 90-160g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2?

PVC corner using;

Q: What is the storage of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2?

Four years under normal weather conditions and use .

Q: What is the package of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2?

Production periods: 30days for 1X40HQ.

- Q:When plastering walls, can alkali-resistant fiberglass mesh be replaced by galvanized steel mesh?

- Before puttying in the stage of decoration, alkali-resistant fiberglass mesh is used to prevent the surface putty from cracking. The price is too large. When the plasterign thickness is equal to or more than 35mm, galvanized?steel?mesh is needed. It wastes too much and it's not easy to operate. Galvanized steel mesh is generally used in the stage of cement mortar whitewashing wall.

- Q:Is glass fiber gridding cloth used more when decorating?

- Currently glass fiber wall cloth (with decorative pattern) is used for decoration due to its beauty, environmental protection, fire resistance and thermal insulation and gridding cloth for style decoration.

- Q:Why is the screen anti-theft screen?

- Steel net screen Fenglv aluminum material of the listed good to meet the development of the market, steel net screen market, meet a considerable part of the customers want to pack a product can achieve the anti theft and anti mosquito desire. Steel mesh screen, whether fixed on the wall or form, will have enough good endurance, not afraid of outsiders invasion. High quality steel mesh screen is all processed by electrophoresis and painting. It is not afraid of damp environment, sun burning or bad environment corrosion. Because the structure is vertically and horizontally interwoven, and the diameter of the line is also 0.8MM, the utility model not only can prevent mosquitoes from entering the room, but also can enhance the ability of prying and shearing.

- Q:Is it first posted mesh or putty?

- It is first pasted mesh, pasting the whole wall is the best, but the mesh is usually used for cracking at the joint, the whole crack?resistance of dacron cloth is better. If it is a new house, decoration has better to do patch treatment; if it is second?decoration, the walls are relatively intact, it is not necessary to paste.

- Q:For wall slot, is seam paper tape or anti-cracking mesh suitable for joints?

- This is easy. You don't have to buy paper tape or mesh. You just need to buy some cheap dacron, but it should be chemical?fiber, not cotton, because after long time , the cotton will easily decay. The chemical?fiber is sealed in wall, so it is aging resistant. Then pour lime into the joint, and cut mesh into small strips, paste them with glue on joints. When they are dry, powder them.

- Q:What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- Mainly refers to the glass composition is different,"Base" refers to a certain amount of alkali metal oxide, Na2O, commonly known as C glass fiber, which corresponds to alkali free (E) glass fiber;

- Q:There are several kinds of glass fiber gridding cloth material yarn.

- More important are quality, tensile strength and environmental protection, and qualified alkali resistance. The commonly used gridding cloth is made of the recycling waste bottles and waste glass through clay crucible process. Such gridding cloth fiber yarn of glass fiber gridding cloth and other various USES gridding cloth not only has unqualified high tensile strength, pungent odor, alkali resistance. It is prohibited to use yarn gridding cloth and exterior wall thermal insulation gridding cloth, grid cloth. The price is 1 yuan. 1.The gridding cloth made of platinum wire-drawing is beautiful while gridding cloth yarn made of platinum wire-drawing is alkali resistant and environmental protection.

- Q:Rock wool board insulation, why add two layers of glass fiber network, and XPS is a layer?

- Rock wool with two layers of mesh cloth and not improve crack resistance, but because wool soft texture, installing the anchor bolt after the surface is uneven, with two layers of mesh is to increase the thickness of the mortar, to find the plane. There is no such phenomenon in the extrusion board.

- Q:What are the raw materials of mesh?

- They are nylon, flax, acrylic fibers, dacron and cotton.

- Q:Self adhesive glass fiber cloth gridding cloth

- The glass fiber gridding cloth mainly adopts alkali glass fiber yarn (with silicate, stability as main components) and made by high-temperature heat setting such as anti alkali liquid and strengthening agent of the special organization structure - lace stitch.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corner Mesh, PVC Corner Mesh 90g/m2 110g/m2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords