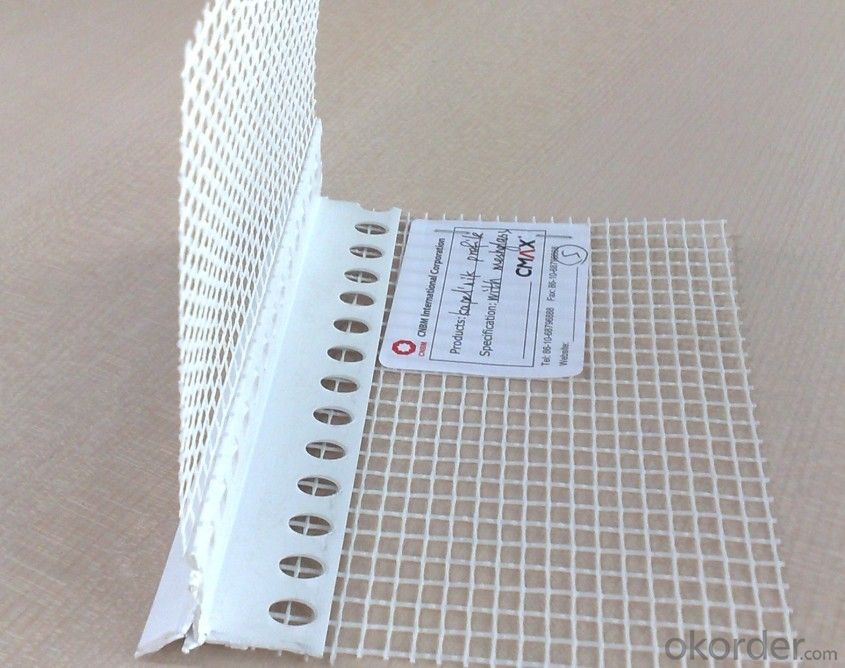

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

MOQ of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality : 5000 Square Meters

Supply Ability of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality: 6000000 Square Meters per Month

Payment Terms of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality: L/C,T/T

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

Specifications of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Place of Origin: China (Mainland)

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Brand Name: CMAX

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Application: Wall Materials

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Width: 1M-2M

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Size: 5*5/ INCH

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Weight: 40gsm to 200gsm

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Weave Type: Plain Woven

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Yarn Type: C-Glass

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Alkali Content: Medium

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality Standing Temperature: 500℃

Glass Fiber Mesh, 4mm*4mm, 145gr/m2, BASF Glue

Product information of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

Name: PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

Use best fiberglass yarn and best glue

Clear and beautiful PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

High strength PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

30 years experience of manufacturing PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

Excellent Priced

FAQ of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

Q: What is PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality?

Coated Alkali-resistant PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality?

Weight: 90-160g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality?

Four years under normal weather conditions and use .

Q: What is the package of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality?

Production periods: 30days for 1X40HQ.

- Q:Are fiber glass lightweight composites?

- Belong to. This definition is not clear, but you want to, ah, metal matrix composite material, there are still light, that can not count ~!"Glass fiber reinforced plastics appeared in the 1940s, not only light, high strength, but also better insulation"

- Q:Which is better, fiberglass mesh or geogrid?

- There are many kinds of geogrid, glass fiber geogrid is only one kind of grille, geogrid also includes polyester grille, steel plastic grille, plastic grille and so on

- Q:What's the difference of common alkali resistant glass fiber gridding cloth and reinforced alkali resistant glaa fiber gridding cloth?

- The construction method are the same while the indicator of breaking elongation rate are different. According to different needs of walls, choose corresponding gridding cloth. On a macro level, reinforced glass fiber is thicker. The indicators are different.

- Q:Why glass curtain cloth is used in super high-rise stone curtain wall?

- The glass fiber reinforced wire mesh is a kind of technology to increase the strength of fragile stone in recent years. The specific process is as follows: the cutting end of the slate material, drying or drying, with multiple fat series liquid crystal glue, glue stone stone stone in the back (the Polish back) evenly. Then the glass fiber reinforced paving to board. Use a stick to level and dry. This method can effectively improve the flexural strength of the stone plate, so that the crushing loss of the plate is greatly reduced. This process can also be added to the production line.

- Q:Specifications of alkali resistant glass fiber gridding cloth

- Refer to the requirements of JG149JG158

- Q:How to DIY the setting adhesive of glass fiber gridding cloth?

- With glass fiber woven fabric as base material, gridding cloth is dipped in and coated with highly resistant polymer emulsion, thus featured by good alkali resistance, flexibility and high tensile resistance in the bidirection of warp and weft. It is widely used for thermal insulation, water proofing and crack resistance of internal and external walls of buildings. The glass fiber gridding cloth mainly adopts alkali glass fiber yarn (with silicate, stability as main components) and made by high-temperature heat setting such as anti alkali liquid and strengthening agent of the special organization structure - lace stitch.

- Q:What kind of fiberglass mesh is needed to touch the outer wall?

- The glass fiber mesh cloth plastering generally for inner wall inner wall and then is the exterior wall hanging wire to heat so that the external walls are used for building on the two is a kind of indispensable not only

- Q:How to tell the quality of mesh cloth?

- The worst fiberglass mesh is very cheap and breaks at two folds. The process is made of clay crucibles. Fiberglass is usually made from some beerBottles made of waste glass. It is prohibited by the state, and its surface coating is not alkali resistant emulsion. From an intuitive point of view: work is relatively rough, generally in the citySell more, often short, easy to shift, and easy to stab the skin. This type of mesh cloth is used in inadequate insulation quality. contact

- Q:Can glass fiber gridding cloth waste be recycled? If can, then what is is?

- The acrylic in grid cloth can produce pungent smell and cause serious soil pollution after high temperature, which proves the environmental protection of glass fiber. It may cause serious air and soil pollution and contain harmful substance to respiratory system. And the core material of grid ding cloth is flame retardant and cannot be burnt.

- Q:What CE certification should glass fiber gridding cloth be done?

- CE certification is a kind of safety certification and regarded as a pass of manufacturer to Europe market.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Corner Mesh, 90g/m2, 4mm*4mm, High quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords