Bulb Flats For Shipbuilding

Bulb Flats For Shipbuilding Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Steel Mesh Panels For SaleBulb Flats For Shipbuilding Supplier & Manufacturer from China

Okorder.com is a professional Bulb Flats For Shipbuilding supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Bulb Flats For Shipbuilding firm in China.Hot Products

FAQ

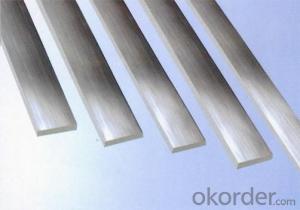

- What is the thickness deviation of 40*4 galvanized flat steel?

- Main application: flat steel is used as a material, used for making iron, tools and machinery parts, and used as frame structures and escalators for buildings

- Steel flat bars are generally stronger and more durable than copper flat bars. Steel has a higher tensile strength and is less prone to bending or warping under heavy loads. Additionally, steel is more resistant to corrosion and can withstand harsh environmental conditions better than copper. However, copper flat bars have superior electrical conductivity and are often preferred for electrical and plumbing applications. Ultimately, the choice between steel and copper flat bars depends on the specific requirements and intended use of the material.

- The main difference between hot-rolled and cold-rolled steel flat bars lies in their production process and resulting characteristics. Hot-rolled steel flat bars are made by heating a steel billet or slab to a high temperature and then rolling it through a series of rollers to achieve the desired shape and size. This process results in a relatively rough surface and rounded edges. On the other hand, cold-rolled steel flat bars are produced by cooling down the hot-rolled steel to room temperature and then passing it through a series of rollers at room temperature. This process results in a smoother surface finish and sharper edges compared to hot-rolled steel flat bars. In terms of physical properties, hot-rolled steel flat bars generally have a larger size tolerance, as the high-temperature rolling process can cause some dimensional variations. Cold-rolled steel flat bars, on the other hand, have a tighter size tolerance due to the controlled cold-rolling process. Additionally, due to the heating and cooling process involved in their production, hot-rolled steel flat bars typically have a scaled surface, which is a thin layer of iron oxide. In contrast, cold-rolled steel flat bars have a clean, smooth surface. Moreover, the mechanical properties of hot-rolled and cold-rolled steel flat bars also differ. Hot-rolled steel flat bars tend to have a lower yield strength and higher ductility, making them suitable for applications that require shaping or bending. Cold-rolled steel flat bars, on the other hand, have a higher yield strength and lower ductility, making them more suitable for applications that require strength and durability. In summary, the key differences between hot-rolled and cold-rolled steel flat bars lie in their production process, surface finish, dimensional tolerance, and mechanical properties. The choice between the two depends on the specific requirements of the application and the desired characteristics of the steel flat bars.

- Yes, steel flat bars are commonly used in the construction of sports facilities. They are often utilized for structural support, such as in the construction of bleachers, fencing, and overhead structures. Steel flat bars provide strength and durability, making them suitable for the demanding needs of sports facilities.

- Steel flat bars are available in various sizes ranging from 1/8 inch to 1 inch in thickness and from 1/2 inch to 12 inches in width. These sizes can vary depending on the manufacturer and specific requirements for a project.

- Steel flat bars are available in a variety of specifications that determine their size, shape, and composition. These specifications encompass dimensions, such as width, thickness, and length, as well as the type of steel utilized and any additional properties. Dimensions for steel flat bars exhibit considerable variation. Widths commonly range from 1/2 inch to 12 inches, while thicknesses can span from 1/8 inch to several inches. Lengths are typically denoted in feet or meters, with standard lengths, such as 6 or 12 feet, readily accessible, or customized lengths tailored to the desired dimensions. The type of steel employed in flat bars also displays diversity. Carbon steel, a fundamental and versatile choice, and stainless steel, which offers resistance against corrosion and presents an appealing aesthetic, are the most prevalent types. Carbon steel flat bars are further categorized based on their carbon content, with low-carbon, medium-carbon, and high-carbon steel constituting widely available options. Moreover, steel flat bars can possess supplementary properties based on their intended utilization. For instance, certain flat bars may undergo heat treatment to augment their strength or hardness, while others may undergo galvanization or coating to heighten their resistance to corrosion. It is important to note that different countries and industries may adhere to their own distinct standards or specifications for steel flat bars. These standards, such as ASTM (American Society for Testing and Materials) or EN (European Norms), ensure consistency and quality across various manufacturers and applications. Consequently, it is crucial to consider these standards and specifications when selecting steel flat bars for a specific project or application.

- Steel flat bars can contribute to the overall aesthetics of architectural designs by adding sleekness, modernity, and a sense of strength. Their clean lines and smooth surfaces create a visually appealing contrast against other architectural elements. Steel flat bars can be used to create eye-catching features like handrails, window frames, or decorative accents, enhancing the overall aesthetic appeal of the building. Additionally, their versatility allows architects to incorporate them into various design styles, from contemporary to industrial, making them a popular choice in architectural projects.

- What about the installation height of the socket and the height of the ground flat steel?

- In accordance with the final use of functional considerations, it is not recommended to reduce the socket installation height. According to the actual use of functional requirements, the socket location can be changed to optimize to avoid the ground flat iron position? If it is not feasible, then reduce the height of ground flat iron.