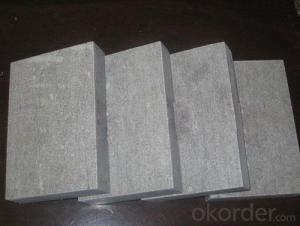

Fiber Cement Boards For Interior Wall Partition/Interior Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

Fiber cement board can be used in exterior wall cladding and facade of various high-class and high rise civil buildings especially in the modern luxurious buildings. Outstanding sound insulation of the system composed with Bysink external wall board can be used in indoor partition and suspended ceiling for the high demand in private request as sound insulation and such as five star hotel, bedroom, and public entertainment.

Also it can be used as the interior partition in the shops, hotels, schools, entertainment places and hospitals.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q:i am building an outdoor BBQ island and i live in an area that snow will fall for a couple of months. i have been researching cement backer board and i cant find any recommendations on snow fall and what type of tyle is best for this application. dont want to make this investment untill i know what i am getting into. any suggestions

- I built a tile inlay on my deck for my grills. It's held up through 3 Wisconsin winters so far. I used pressure treated plywood for a base, then installed Durock over the plywood. Use Flexbond thinset for adhering the tiles. My neighbor owns a flooring store, and he set me up with an epoxy grout. You have to work it quickly to avoid a mess, but it's very durable. Hope this helps. EDIT: I would recommend using the plywood to give the Durock additional support. If you can enlarge the opening enough to wrap the Durock around the edge, you should be good. The tile and Durock should provide enough protection to keep the plywood from burning. If that will be an issue, you can screw some pressure treated 2x4's along the length of the metal frame, spaced every 16 or so, and then screw the Durock to that. This will give the top support so it won't deflect under the weight of the tile and snow, and keep the tile from popping. Good luck.

- Q:FC sound-absorbing board is what material

- According to the different sandwich layer, can be divided into lightweight concrete, polystyrene foam and honeycomb sandwich and other composite wall panels.

- Q:What can I put on the two walls that have the cement backer board? Is there only certain things that I can put on them. They are about 3 ft. away from the stove. What is the code for this. I am at a loss, but I need to do something about this. Anyone know about wood stove codes. Thanks...

- Fireplace shops sell different types of wall boards than meet most building codes. Try to find a dealer that sells your brand of wood stove. They should have access to manufacturers recommendations on safety clearances. You might also get the information on line. Give them the model of your wood stove.

- Q:I am making a custom kitchen island and I planned to tile the top of it. The top of the island is going to be made of thick plywood for strength and I was told by the man at the hardwood store where I bought all the supplies that I needed to place cement board down on the plywood before I placed the tile down. I had bought a trim to go around the table top, hoping that it would be flush with the tile once the time went into place, however using the cement board makes the trim flush with the cement board and after the tile is installed, it would be about 5 mm taller than the trim. Do I really need to use the cement board? Would it be a bad idea to place the tile and mortar directly on the plywood?

- Use a slightly thinner plywood and glue it to the backer board. You will have adeqaute strength from the laminate and superior water protection from your backer board... The thicker plywood will find some use... it always does. If there is still any concern about table strength, redesign/ add to the table skirt (kind of like joists for a table top). why make it OK when you can make it great with a small amount of additional effort?

- Q:Cement fiber wall hanging board PVC wall hanging board which is good?

- Cement fiber board if it comes with insulation, you can stick + anchor technology, do not need to dry hanging ah, save more!

- Q:almost finished with tiling on cement board wall. ran into problem with corner applying bull nose piece.?

- Since you don't tell us what your problem is, it's a little difficult to help you. In the future, completely lay out your tile project dry, so you don't run into any surprises.

- Q:How to solve the old concrete and the new pouring between the concrete does not leak it?

- If the walls can be opened on both sides of the wall, it is recommended to use I-beam or angle steel as a new pouring concrete slab support beam, in the I-beam or angle above a layer of fiber cement board as a permanent template, and then pouring concrete.

- Q:Can the cement pressure plate be directly put on the top of the paint?

- Yes, but the cement pressure plate (plate) surface is relatively smooth, directly in the cement pressure plate (plate) on the batch of putty powder or painted latex paint prone to fall off

- Q:Bought new ceramic tile for kitchen and the old stuff is hard to get up. I want to keep the cement board that is in there for the new stuff.

- if the old tile was properly installed, it will be close to impossible to keep it intact when removing it. backerboard is cheap......

- Q:i am trying to build a slideboard (he kind that speed skateres and hockey players use) by gluing a piece of particle board to a sheet of tileboard.yesterday i applied a generous amount of contact cement and put the two together immediately to dry. today they are not even sort of stuck together. what is the most likely cause?could it be because i did this in my dingy and freezing cold basement?or are you not supposed to use contact cement on particle board and or tileboard?the instructions did call for plywood and linoleum.

- Contact adhesive should be applied to both surfaces and then allowed to set for about 20 - 30 minutes (until almost touch-dry) BEFORE bringing the surfaces together. BEWARE! Once the surfaces touch they will bond instantly, with no scope for repositioning. Leave the existing cement until thoroughly dry, then re-apply as per my instructions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Boards For Interior Wall Partition/Interior Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords