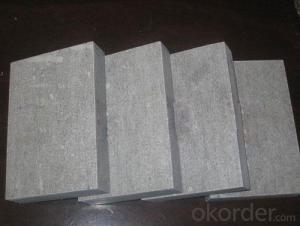

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q:How do fighters break ice, cement and wood blocks without breaking their hands, arms, legs and feet?

- strength of mind. cement, when hit correctly can break like a twig but it requires perfect breathing, a strong hand and a psychotic mind. u have to be completly nuts to try and break cement. breaking is is possible but......highly unlikely to happen. it would have to be a foot not a hand to break it. and i could break 10 boards if they each have a cm between each one. its about using the force of the first board to bread the others. so if your smart and good enough ur really only breaking half of them.. the pressure and weight is going to break the rest of them.

- Q:how do those karate guys break cement and wood pieces by jsut like one hit, why doesnt it hurtthem or break there hands and feet?dont gimme a BS answer,im lookin for an actual reasonable explanation

- wood is easy to break against the grain. Cement requires you to spend lots of time conditioning you knuckles so you don't break them but it is possible for anyone with spare time to condition to break cement and bricks(some people start with ceiling tile). How ever there are masters in Japan that can punch a tree full strength with out breaking knuckles and master in Korea that can break Marble and i believe there is one that punched a ox and it died

- Q:Fiber cement board and the difference between the water board

- Water board, also known as decorative concrete, is a water concrete slab. Different from ordinary concrete, it is smooth surface, uniform color, angular, no damage and pollution, but in the surface coated with a layer or two transparent protective agent, it is very natural, solemn.

- Q:i am going to be installing tile in my bathroom as a tub surround.i am wondering what backer board is needed. if i am using a membrane such as kerdi, is drywall a good enough backer or do i need cement board. if i need cement board, do i need the membrane? what products do you suggest for best installation. i will also be doing a walk in shower. are there any differences to be aware of compared to the tub surround shower style.

- Tile doesn't flex. Drywall does. You need a hard surface to lay tile, or the grout joints will crack, water will get in, and your tile will promptly fall off. Real tile backer board (the kind that's made out of fiber re-enforced cement) is the only decent solution for installing tile over a wood frame. Hardibacker or any other modern garbage designed to make something seemingly easier, just turns into a nasty headache a year later. Also be sure to use real thin-set mortar, and real grout. That adhesive grout is just acrylic caulking with some sand added, tiles will fall off if they get wet.

- Q:What are the brands of cement fiberboard

- Fiber cement board excellent quality are: 1, Guangzhou Etneite company's Eide board, 2, Jiangxi Yichun special production company Kent KT board (also in Foshan Nanhai and Xinjiang Korla also have factories), 3, Zhejiang Ningbo Yi and the company's production of easy and board 4, Jiangsu Suzhou Fu Fu Xi company's production of the FC board, 5, Shandong Lutai company production of Lutai board 6, Anhui Chuzhou three music company produced three music board

- Q:the cement boards are ahold by 1 nails

- Hardyboard is a composite/concrete siding that may work. If your boards are only slightly damaged you may be able to patch them with concrete patch then repaint. A lot cheaper than replacing.

- Q:How the cement pressure plate sticks on the brick

- Base treatment: the dust, debris thoroughly cleaned, no hollowing, cracking and sand and other defects. Pin line: before the construction of the wall around the height of the pop-up control line, in the ground pop-up cross-line to control the floor tile size.

- Q:What are the differences between the gypsum board and the cement pressure plate and the Eide board?

- Ette board is a fiber reinforced silicate plate (fiber cement board), the main raw material is cement, selected minerals, by the high temperature autoclaved autoclaved, waterproof performance, can be used as toilet Wall, or outdoor roof roof, or external wall with the board can be in the long-term damp environment to maintain stable performance unchanged.

- Q:Two centimeters thick cement board is always cracked

- Thickness is not enough, the normal playing cement board need to add pebbles or claw stone, the thickness of at least 5cm, 2cm cement board in order to not crack, inside put steel cafe, very cheap.

- Q:i am wondering the durablability difference. Is one more sturdier than the other?

- Some insurance company's do not write policy's for fiber cement homes. If there is water damage, for instance, behind the siding, it is not often discovered in time to have a small claim. The claims have been huge, in some cases. Also, I have seen this type of siding damaged by wood peckers.. The bird can detect an insect or larvae behind the siding and go after them leaving behind numerous holes.. In my opinion, stone veneer is almost as good as brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords