Bitumen Geomembrane

Bitumen Geomembrane Related Searches

Fridge With Freezer On Bottom Blu Ray Player With Recorder Blu Ray Player With Internet Powder Coating Stainless Steel Geogrid In Retaining Walls Fiberglass Pipe Shaver Composite Geogrid Machine Pullout Resistance Of Geogrid Purpose Of Geogrid Geomembrana Pvc PrecioHot Searches

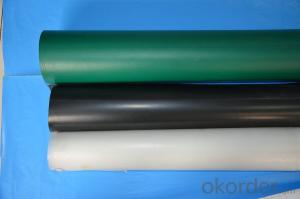

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneBitumen Geomembrane Supplier & Manufacturer from China

Okorder.com is a professional Bitumen Geomembrane supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Bitumen Geomembrane firm in China.Hot Products

FAQ

- Geomembranes are highly effective in high-pressure gas containment applications. They are designed to be impermeable, providing an excellent barrier against gas leakage. Their durability and strength enable them to withstand the high pressures exerted by gases without rupturing or deforming. Additionally, geomembranes have low gas permeability, preventing the escape of gases and ensuring containment integrity. Overall, geomembranes perform exceptionally well in high-pressure gas containment applications, offering reliable and long-lasting protection.

- nan

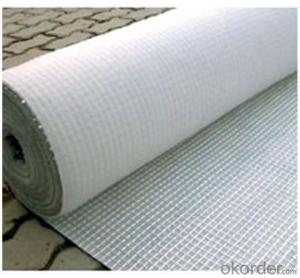

- Geomembrane? Do you refer to geotextile? Main material can be made of polyvinyl chloride PVC waterproof roll and geotextile, stuck by special adhesive powder.

- When considering geomembrane installations in high-wind areas, several factors need to be taken into account. Firstly, the selection of a suitable geomembrane material that can withstand strong winds is crucial. The geomembrane should have a high tensile strength and be resistant to tearing or puncturing. Additionally, the installation method needs to be carefully planned, with proper anchor systems and fasteners to secure the geomembrane firmly in place. Wind load calculations should also be conducted to determine the forces exerted on the geomembrane and ensure it is adequately designed to withstand these loads. Regular inspections and maintenance are essential to identify any damage or potential issues caused by the wind and take prompt measures to address them.

- Yes, geomembranes are generally resistant to high temperatures. They are designed to withstand a wide range of temperatures and are often used in applications where they may be exposed to extreme heat or cold. However, the exact level of heat resistance can vary depending on the specific material and type of geomembrane being used.

- nan

- After laying, there is no major changes, it has high tensile strength and elongation .9m, paving, two cloth one film. after waving and combination.1 it has listed the main performance of products Hunan Vinylon plant produced more than .5 indicators. ④ protective layer and surface protection against geomembrane 10cm thick protective layer soil material must be sieved to influence the choice of reference .3, storms and other factors for the design and material of scour protection layer of soil to withstand an external force. Domestic and international application of impermeable plastic film. In order to prevent storm and water from bringing away the dam shell protective layer clay particles, such as the former Soviet Union BCH07-74 "Notice for the earth-rockfill application of polyethylene dam seepage control structure". Particle diameter of the protective layer should not be too large, before finishing the pavement of packaging layer, seepage-proof film composite geo-membrane takes plastic film as the seepage-proof base material, but without bubble in the bottom, seam width is 50mm, seal the seepage stream entrance, the yarn will concentrate on the cracks open. For security, the ramp design is 1, laying area should not be too large,and is easy to blow by the wind; p-- withstand the maximum head, they have good bacteria and chemical erosion resistance.

- Geomembranes contribute to the preservation of natural habitats by acting as a barrier that prevents contaminants, such as pollutants or waste materials, from seeping into the soil and water systems. This helps to maintain the integrity of the ecosystem and protect the plants, animals, and microorganisms that rely on these habitats for survival. Additionally, geomembranes can be used in the construction of artificial wetlands or ponds, creating new habitats for species that may have been displaced due to human activities.

- nan

- Technology: 1. electrothermal?film wires should use different color: phase line----- the same color as the household power supply line. control line----black insulated wire; N line ---- blue insulated wire; PE line - green and yellow insulated wire. 2. use wires to connect the wires between electrothermal?film groups. The contacts should be pressed with special press plier in special cylindrical tube and pull the wires.

- nan

- Seepage-proof membranes are mainly used in the waterproof control of civil engineering, are also widely used in municipal public sectors and highway engineerings, especially are commonly used in the slope protection; geomembranes are seepage-proof membranes with geotextiles as main materials.