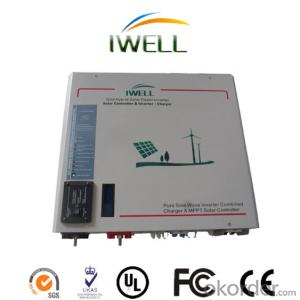

250 Kw Solar Inverter

250 Kw Solar Inverter Related Searches

Standing Seam RoofHot Searches

Type Of Inverter For Solar Types Of Inverter For Solar Used Solar Inverter For Sale Inverter Size For Solar System Solar Edge Inverter For Sale 5kw Solar Inverter For Sale Solar Inverter For Sale Solar Inverter For Battery Solar Inverter For Split Ac Solar Inverter For Laptop Solar Inverter For Fridge Solar With Inverter Price Solar Inverter With 2 Battery Solar Inverter Price In China Best Solar Inverter In China Solar Inverter Price In Dubai Solar Inverter Price In Uae Solar Inverter Price In Kenya Solar Inverter Price In Kerala Solar Hot Water Collectors For Sale250 Kw Solar Inverter Supplier & Manufacturer from China

Okorder.com is a professional 250 Kw Solar Inverter supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 250 Kw Solar Inverter firm in China.Hot Products

FAQ

- What should be paid attention to when welding the air conditioner copper pipe welding machine?

- Don't let out the water,

- What is the welding machine for glass fibre reinforced plastic cable protection tube?

- The glass fiber reinforced plastic material joint is only suitable for bonding and riveting. It can not be welded, so there is no special welding machine.

- Which brand is the best for plastic pipe welding machine? How to ensure the quality of PE pipe welding machine?

- Domestic rings around this brand is pretty good, and many Gas Co designated to use this house

- How to weld the air conditioner copper tube welding?

- How can the air conditioning copper tube and copper pipe be welded?Copper tube and copper tube welding is generally used silver electrode (its silver content is 25%, 15% or 5%) or copper and phosphorus series welding rod, they all have good fluidity, do not need welding flux. Specific welding procedures are as follows:1) welding copper tube processing: expansion and deburring, old copper pipe must also use abrasive paper to remove oxide layer and dirt. When the diameter of the welded copper pipe is different greatly, it is necessary to clamp the pipe with big diameter in order to ensure that the gap between welds should not be too large.2) nitrogen filling: the copper pipe is filled with nitrogen to carry out welding, which can make the inner wall of copper tube bright, clean and oxide free, so as to effectively control the cleanliness of the system.3) open the welding torch, adjust the mixture ratio of oxygen and acetylene, and choose neutral flame.4) first heated by the flame tube insertion, slightly hot after the flame moves outward a little casing, heating the pipe when the pipe joint uniformly heated to the welding temperature (micro solder (red), adding silver electrode or phosphorus brazing). By the solder melting temperature, and flame temperature maintaining outer flame pipe joints, and not using pre solder melt drip welding joints, then heating welding, otherwise it will affect the strength and density of joints.5) remove the flame and close the torch. Check the quality of the weld. If there is a gap or a sand heel in the weld, re weld the weld