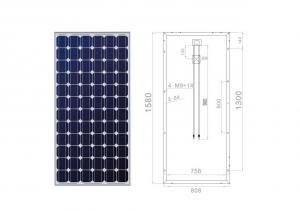

HBM(250) Polycrystalline Silicon Solar Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

About us

Hope Group is a high-tech group wich specializes in solar products design,research, manufacture, sales,solar projects design and installation. There have three subsidiaries.

We have been engaged in PV manufacture and research industry for more than 20 years. We also own powerful technical resources and experienced research team in Hope Group.

We have the first class manufacture equipments and plant.Hope Group are qualified for many international and national authentications of TUV、IEC61215、IEC61730、CE and “ Golden Sun” in China PV industry, meanwhile ISO9001-2008, ISO14000, OHSAS18000, REDP and the certification of Hi-tech enterprise etc./ ( NDRC/GEF/WB-be selected in Chinese renewable energy development projects).

Hope Group have advanced and integrated industry chains, including solar mono-silicon rods, poly-silicon ingots, wafer, solar cells, solar module and solar serial applications. We also have experienced and energetic sales team.

Our national sales service covers seven parts, including northeast, north, east, middle, south, northwest and southwest, international sales covers five continents and over forty countries, including Germany, Italy, Spain, France, America and Brazil etc. There is high efficient , specialized and experienced management team in Hope Group.

Our present annual capacity is 6 million for wafer, 60MWp for solar cells,200MWp for solar modules and one hundred thousand for solar applications. It is expected that the annual capacity of 2012 will be up to 30 million for wafer,300MWp for solar cells, 1000MW for solar modules and 2 million for solar applications.

Data sheet

| Maximum Power | 250W |

| Efficiency | 0.154 |

| Backsheet | Silver |

| Frame Color | White |

| Manufacture Site | China |

| Frame | Anodized Aluminnum Alloy |

| Weight | 19KG |

FAQ:

1. How long will my inquiry get response?

Your inquiry related to our products or prices will be replied within 24 hours.

2. Can I get professional service and suggestion?

Well-trained and experienced staffs to answer all your questions in fluent English.

3. Do you accept OEM or customized design?

OEM & ODM, any your customized lightings we can help you to design and put into product.

4. What if I need specific design?

Distributorship are offered for your unique design and some our current models.

- Q:Can solar panels be installed in rural areas?

- Yes, solar panels can be installed in rural areas. In fact, rural areas often have more space and sunlight, making them ideal for solar energy generation. Installing solar panels in rural areas can provide access to clean and renewable energy, reduce reliance on fossil fuels, and bring electricity to remote communities that are not connected to the grid.

- Q:Im doing this project on Solar panels and im not so sure what they are!some questions i have are who invented them and what were they invented? If u could know anything on Solar Panels i would love to hear it. Thanks!!!!!!!!!!!!!!!!!!!!!

- Solar Panels are collections of solar cells. These panels basically collect the incoming sun's electromagnetic radiation and convert it into electrical energy. A solar cell is any device that directly converts the energy in light into electrical energy through the process of photovoltaics. The development of solar cell technology begins with the 839 research of French physicist Antoine-César Becquerel. Becquerel observed the photovoltaic effect while experimenting with a solid electrode in an electrolyte solution when he saw a voltage develop when light fell upon the electrode.

- Q:How do solar panels affect the property's energy consumption?

- Solar panels can significantly reduce a property's energy consumption by generating electricity from sunlight, thereby offsetting the need to draw power from the grid. This helps to lower utility bills and decrease reliance on fossil fuels, leading to both financial and environmental benefits.

- Q:Can solar panels be installed on a garage or carport?

- Yes, solar panels can be installed on a garage or carport. In fact, these structures often provide ideal locations for solar panel installation due to their large, flat rooftops or open spaces. Installing solar panels on a garage or carport can help maximize energy generation, reduce electricity bills, and provide shade for vehicles or additional usable space.

- Q:Someone Said It costed them 50,000 To Install Solar Panel In their House and 35,000 For Installation. Is that true?

- It depends on the number and size of the panels. The minimum charge for a small bungalow would be at least $20,000 labor and material.

- Q:Why does the new 200 Toyota Prius have solar panels at the top of the vehicle?

- Hi, the solar powered-venting system is not air conditioning, it is simply a venting system to attempt to balance the interior temperature of the Prius with the outside temp when the interior of the Prius is at least 68 degrees. This is an optional system and is available as a stand-alone option for $800.00 or $3600.00 in conjunction with the navigation system. The solar roof is integrated into a full function sunroof, but the sunroof can be opened without using the solar venting portion. There is a separate portion of the system that will allow the driver to turn on the electric AC for three minutes, if there is enough stored charge in the nickel metal hydride (NiMH) hybrid battery. The AC is not linked to the lead acid battery, and is run by the NiMH only, not the gas engine. The NiMH and lead acid are two separate power systems. The solar panels do not power anything else in the Prius and do not boost the power to any of the systems. The solar venting does permit less energy from the NiMH to be utilized for AC at the next startup. For trivia, the EPA will not allow Toyota to install the solar venting system on Prius with the top package V (#5). The EPA feels the Prius is too top heavy with all the additional sensors required for the radar guided cruise control and all the other high tech components in the top end option package, just FYI.

- Q:Can solar panels be used to power a university?

- Yes, solar panels can be used to power a university. By installing a sufficient number of solar panels on campus buildings or in open spaces, universities can generate a significant amount of clean and renewable energy. This can help reduce reliance on fossil fuels, decrease electricity costs, and contribute to a more sustainable campus. Additionally, advancements in solar technology have made it more efficient and affordable, making it a viable option for universities looking to transition to renewable energy sources.

- Q:Was looking at 0w solar panel kit. Does this mean, all I can use is something like a 0W CFL light bulb and nothing else?

- No. The way to set it up is to store the power generated by the solar panel in a battery, then use the battery to power your lights, radio, etc, when you need the power. A standard deep-cycle marine battery is typical for panels of this size (WalMart for approx $90). A 0W panel will generate between 30 50 Watt-Hours of power over the course of a day (May-Aug weather-dependent), so this would equate to running a laptop for -2 hours, or a 0W CFL light for 3-5 hours, or a 20W stereo for .5-3 hours, etc. I find it is much easier to speak in terms of watts. Divide the watt-hours by the watts of the appliance to get the number of hours it can run. Hope that helps!

- Q:Can solar panels be installed in a community or neighborhood?

- Yes, solar panels can definitely be installed in a community or neighborhood. In fact, installing solar panels at a community or neighborhood level can have several benefits. It allows for a more cost-effective approach, as the installation and maintenance expenses can be shared among multiple households. Moreover, it promotes a more sustainable and environmentally friendly energy source, reducing reliance on fossil fuels and lowering carbon emissions. Additionally, community solar projects encourage collaboration and community engagement, fostering a sense of unity and shared responsibility towards a greener future.

- Q:I would like to know of any construction companies, road crews, or any company that uses solar panels in the Tampa area and throws them away. I like to recycle solar panels by repairing and processing what power I can from them. Know any companies that throw out used solar panels? If so, can you provide the name and number?

- Check out home power magazine for the list of vender's. Construction companies typically return damaged panels to the distributor or manufacturer for credit. The companies may have an inventory of goods for sale. Also, check out large insurance companies (Nationwide) to see what they do with panels they write off as catastrophic loss when a homeowner or business files a claim. Hope this helps

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HBM(250) Polycrystalline Silicon Solar Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200000 watt

- Supply Capability:

- 20000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords