18J Rebar

18J Rebar Related Searches

Hot Rolled Steel Blue Steel Rebar Aisi 1020 Hot Rolled Grade 80 Rebar Rebar Lengths Standard Rebar 10Mm 30M Rebar T10 Rebar Rebar Identification 18J RebarHot Searches

12Mm Mdf Price Hot Rolled Steel Price Hot Rolled Steel Prices18J Rebar Supplier & Manufacturer from China

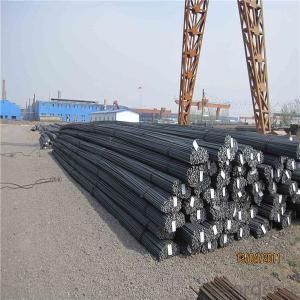

Okorder.com is a professional 18J Rebar supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 18J Rebar firm in China.Hot Products

FAQ

- There are several types of steel rebars commonly used in retaining wall constructions, including plain carbon steel rebars, epoxy-coated rebars, galvanized rebars, and stainless steel rebars. Each type has its own unique properties and benefits, such as increased corrosion resistance or enhanced durability, allowing for the selection of the most suitable option based on the specific requirements of the retaining wall project.

- The role of steel rebars in minimizing creep deformation in concrete is to provide added strength and stiffness to the structure. By reinforcing the concrete with steel rebars, it helps to resist the long-term deformation caused by creep, which is the gradual deformation that occurs under sustained load over time. The rebars act as a reinforcement, reducing the amount of deformation that the concrete experiences and enhancing its ability to withstand long-term loads without significant creep.

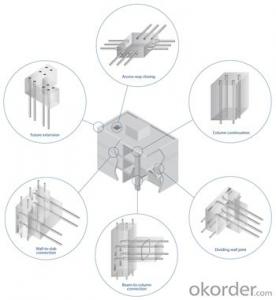

- Yes, steel rebars can be used in architectural applications. They are commonly utilized in reinforced concrete structures to provide strength, durability, and structural integrity. Steel rebars are frequently used in architectural designs to reinforce beams, columns, slabs, and other elements, ensuring the stability and longevity of the building.

- Steel rebars have minimal impact on the overall sound insulation of a building. While they may conduct sound to a small extent due to their rigid nature, the primary factors affecting sound insulation are the materials used for walls, floors, and ceilings, as well as insulation materials. Steel rebars are typically embedded within concrete structures and do not significantly contribute to sound transmission between spaces.

- Yes, steel rebars are susceptible to rust. Rebars are typically made of carbon steel, which contains iron. When exposed to moisture and oxygen, iron reacts to form iron oxide, commonly known as rust. This process is accelerated in the presence of salt or other corrosive substances. Rust formation weakens the rebars and can eventually lead to structural damage if left untreated. Therefore, it is crucial to protect steel rebars by applying an appropriate coating or using other corrosion prevention methods to ensure the longevity and structural integrity of reinforced concrete structures.

- Yes, steel rebars can be used in modular construction. Steel rebars are commonly used as reinforcement in concrete structures, including those found in modular construction. They provide strength and durability to the modular units, ensuring their stability and structural integrity.

- The process of bending steel rebars into shapes other than straight bars typically involves using specialized machinery, such as a rebar bending machine or a hydraulic bender. The rebars are placed in the machine, which applies force to bend them into the desired shape. The operator may follow blueprints or use templates to ensure accurate bending. This process is commonly used in construction and concrete reinforcement projects to create custom shapes that fit specific architectural or structural requirements.

- There are several types of steel rebars commonly used in precast concrete constructions, including plain round bars, deformed bars, epoxy-coated bars, stainless steel bars, and galvanized bars. Each type offers specific properties and advantages depending on the project requirements and environmental conditions.