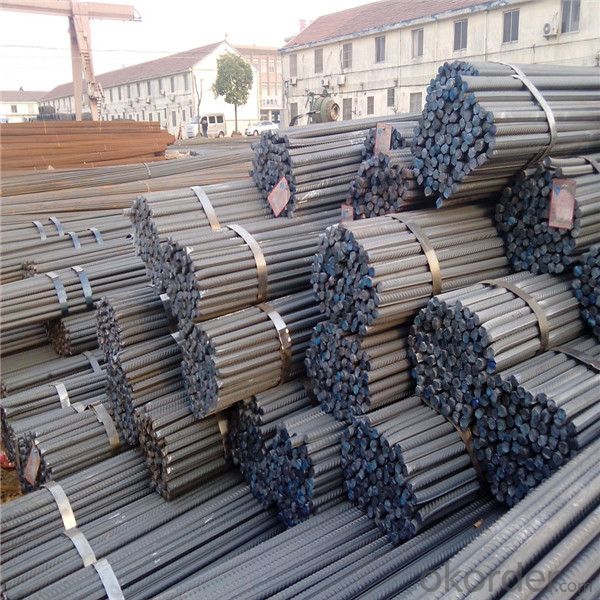

Iron rods for construction in stock for sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel rebar is bars of steel commonly used in construction, especially for reinforcing concrete structures such as

driveways, foundations, walls, and columns. These bars come in different sizes and strength grades, and can be

smooth or may include deformations that provide greater adhesion for concrete poured over the bars. When used

in poured concrete, the bars are typically placed in a grid pattern, the concrete poured over them, and then readjusted

to maintain the proper shape while the concrete sets. Steel rebar can be purchased from a number of manufacturers

and is often found at construction retailers or large hardware stores

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:Can steel rebars be used in structures with high levels of carbonation or acid attack?

- Structures with high levels of carbonation or acid attack should avoid using steel rebars. Carbonation occurs when alkaline compounds in concrete react with carbon dioxide from the atmosphere, resulting in a decrease in the concrete's pH level. This can cause the corrosion of steel rebars, as the lower pH levels create an acidic environment that promotes rusting. Similarly, acid attack happens when structures come into contact with acidic substances like industrial chemicals or acid rain. Acidic environments accelerate the corrosion process by further lowering the pH levels of the concrete, increasing the risk of steel rebar deterioration. To prevent these problems, structures exposed to high levels of carbonation or acid attack can use alternative materials such as stainless steel, epoxy-coated rebars, or fiber-reinforced polymer rebars. These materials possess improved corrosion resistance properties, ensuring better durability in challenging environments. It is essential to consider the specific conditions in which the structure will be exposed and seek advice from structural engineers to select the most suitable materials for long-term performance and safety.

- Q:What is the process of pre-stressing steel rebars?

- The process of pre-stressing steel rebars involves applying a predetermined amount of stress or force to the rebars before they are subjected to loading. This technique is commonly used in the construction industry to improve the structural strength and durability of concrete structures. The process typically starts with the selection of high-strength steel rebars that have good tensile strength properties. These rebars are usually made from carbon steel or alloy steel and come in various sizes and shapes, depending on the specific application. Once the rebars are selected, they are cleaned and coated with a protective layer to prevent corrosion. After that, the rebars are placed into the desired position within the concrete structure, such as beams, columns, or slabs, according to the design specifications. Next, the pre-stressing process begins. There are two primary methods for pre-stressing steel rebars: pre-tensioning and post-tensioning. In pre-tensioning, the rebars are initially tensioned by fixing them to an anchorage point or a strong frame. The opposite end of the rebars is then pulled using hydraulic jacks or mechanical devices, applying a significant amount of force. Once the desired stress is achieved, the rebars are secured in their stressed position by casting concrete around them. After the concrete has hardened, the jacks or devices are released, transferring the stress to the rebars. In post-tensioning, the rebars are first placed into the concrete structure without any initial tension. After the concrete has hardened, a series of ducts or channels are created within the structure, running along the path of the rebars. High-strength steel strands or cables are then inserted through these ducts. The strands are anchored at one end of the structure and tensioned using hydraulic jacks or similar devices. This tensioning process applies a force to the rebars, which is transferred to the concrete, compressing it. Once the desired stress is achieved, the strands are secured and the ducts are filled with grout or mortar to protect them from corrosion. Both pre-tensioning and post-tensioning techniques result in pre-stressed steel rebars that provide several benefits to concrete structures. These include increased load-carrying capacity, improved resistance to cracking and deformation, enhanced durability, and overall better structural performance. The process of pre-stressing steel rebars is a vital aspect of modern construction practices, ensuring the longevity and safety of various types of concrete structures.

- Q:What are the different types of steel rebars used in airport construction?

- To ensure the durability and structural integrity of airport infrastructure, a variety of steel rebars are utilized in airport construction. Airport construction commonly employs the following types of steel rebars: 1. Mild Steel Rebars: These rebars, made from carbon steel with a smooth surface, are the fundamental and widely used reinforcement in airport construction. They provide general reinforcement and are applicable to airport runways, taxiways, and aprons. 2. High Strength Deformed (HSD) Steel Rebars: HSD rebars undergo a heat treatment process, enhancing their strength and ductility. These rebars have ribbed surfaces that adhere better to concrete, making them ideal for critical structural elements like beams, columns, and foundations in airport construction. 3. Epoxy-Coated Rebars: For environments prone to corrosion, epoxy-coated rebars are employed. These rebars have an epoxy resin coating that shields the steel from moisture and chemicals in concrete. Epoxy-coated rebars are frequently used in airport construction, particularly in areas exposed to corrosive substances and de-icing salts. 4. Stainless Steel Rebars: Stainless steel rebars possess excellent corrosion resistance and are commonly utilized in coastal airports or high-humidity regions. They are especially suitable for reinforcing concrete structures in airport terminals, hangars, and other areas where durability and aesthetics are crucial. 5. Galvanized Rebars: Galvanized rebars are coated with a layer of zinc to protect against corrosion. They are commonly used in areas with high moisture content or where concrete is exposed to harsh weather conditions. In airport construction, galvanized rebars reinforce structures such as retaining walls, drainage systems, and other external components. 6. Welded Wire Fabric (WWF): WWF consists of parallel and perpendicular steel wires welded to form a mesh-like structure. This rebar type is employed in airport construction for concrete slabs, pavements, and large surface areas. WWF ensures uniform reinforcement and even distribution of loads across the structure. It is essential to consider specific factors such as application, structural requirements, environmental conditions, and local building codes when selecting steel rebars for airport construction. Consulting with structural engineers and construction professionals is crucial to determine the most suitable type of steel rebar for each application in airport construction projects.

- Q:What are the different uses of wire rod and thread steel?

- Thread steel is widely used in housing, bridges, roads and other civil engineering construction. From the highway, railway, bridges, culverts, tunnels, dams, flood control and other public facilities, small building foundation, beams, columns and walls, plates, rebar structure is indispensable material.

- Q:Can steel rebars be used in the construction of residential communities?

- Steel rebars are a popular choice in the construction of residential communities. They are extensively utilized in the construction industry to reinforce concrete structures, including residential buildings. By enhancing the load-bearing capacity and resistance to cracks and other structural damages, they provide durability and strength to the concrete. In residential construction, steel rebars are commonly employed to reinforce foundation footings, walls, columns, and beams. This reinforcement ensures the building's structural integrity, leading to a safer and longer-lasting structure. Moreover, steel rebars can be easily customized and shaped according to specific design requirements, allowing for flexibility in construction. All in all, the use of steel rebars in residential communities is widely accepted and a prevalent practice in the construction industry.

- Q:How do steel rebars affect the overall workability of concrete?

- Concrete's overall workability is significantly improved by steel rebars. Workability refers to how easily concrete can be mixed, placed, compacted, and finished to achieve the desired shape and surface. The incorporation of steel rebars into concrete provides reinforcement and enhances its structural strength. These rebars act as a skeleton within the concrete matrix and evenly distribute loads and stresses throughout the structure. This reinforcement prevents cracking, improves structural integrity, and increases the concrete's load-bearing capacity. Steel rebars also aid in controlling shrinkage and cracking in concrete. During the curing process, concrete tends to shrink, leading to crack formation. However, the presence of rebars counteracts the tensile forces causing shrinkage and cracking, thus enhancing the concrete's overall durability. In addition to their structural benefits, steel rebars also facilitate concrete workability during construction. They guide proper concrete placement and prevent mix segregation or separation. These rebars ensure proper compaction, eliminating potential voids or air pockets and resulting in a more uniform mixture. Furthermore, steel rebars provide stability and support to concrete during curing and hardening stages. They prevent deformation or sagging of fresh concrete, ensuring it maintains its desired shape and form. This is particularly crucial for complex or intricate structures requiring precise shaping and positioning. Overall, the inclusion of steel rebars positively impacts concrete workability by enhancing structural strength, mitigating shrinkage and cracking, facilitating proper placement and compaction, and providing stability during the curing process. The combination of concrete and steel rebars creates a durable and reliable construction material capable of withstanding various loads and environmental conditions.

- Q:Can steel rebars be used in earthquake-resistant construction?

- Yes, steel rebars can be used in earthquake-resistant construction. Steel rebars are commonly used in reinforced concrete structures to increase their strength and durability, making them better able to withstand seismic forces during an earthquake. The use of steel rebars helps to distribute the energy generated by the earthquake, reducing the risk of structural failure and enhancing the overall resilience of the building.

- Q:What are the common quality tests performed on steel rebars?

- The common quality tests performed on steel rebars include visual inspection, dimensional measurement, tensile strength testing, bending test, weldability test, and corrosion resistance test.

- Q:Are steel rebars suitable for high-rise buildings?

- Yes, steel rebars are highly suitable for high-rise buildings. Steel rebars provide excellent tensile strength and reinforcement to concrete structures, making them ideal for withstanding the heavy loads and stresses experienced in tall buildings. Additionally, steel rebars offer durability, flexibility, and cost-efficiency, making them a preferred choice in constructing high-rise buildings.

- Q:What is the effect of moisture content on the strength of steel rebars?

- The strength of steel rebars can be significantly affected by their moisture content. When exposed to moisture, particularly water or high humidity, corrosion can occur. This happens when the moisture reacts with the iron in the steel, resulting in the formation of iron oxide or rust. As a result, the steel rebars weaken and their overall strength is reduced. Moisture presence speeds up the corrosion process, causing the gradual loss of structural integrity in the steel rebars. Corroded rebars become brittle and are more prone to fractures or failure when subjected to a load. This can be especially problematic in construction projects that utilize steel rebars to reinforce concrete structures, as the corrosion compromises the durability and safety of the entire structure. Moisture not only directly impacts the strength, but it also contributes to other issues such as cracking, spalling, and concrete degradation. When moisture interacts with the concrete surrounding the steel rebars, it leads to expansion and contraction, resulting in internal stress and potential damage. This further weakens the rebars and the overall structure. To counteract the negative effects of moisture on steel rebars, several protective measures can be adopted. These measures may include the use of corrosion-resistant coatings like epoxy or zinc, which act as a barrier between the rebars and moisture. Additionally, ensuring proper drainage and ventilation in construction projects can prevent the accumulation of moisture, reducing the risk of corrosion and maintaining the strength and longevity of the steel rebars. In conclusion, it is vital to carefully consider the moisture content and its potential impact on steel rebars in any construction project. By addressing and managing moisture, engineers and builders can guarantee the structural integrity and safety of the steel rebars, ultimately improving the strength and durability of the entire structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Iron rods for construction in stock for sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords