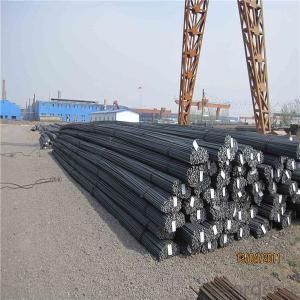

Deformed iron rods for construction building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

steel rebar is metal bars often used in construction for pouring concrete or supporting walls and columns. The

rebar can be smooth, though they are frequently manufactured with deformations that create greater texture to

which concrete can adhere, creating a stronger bond that helps prevent cracking of concrete. These deformations

do not create weaknesses in the rebar, and when rebar is measured to determine its diameter, it is typically measured

at the narrowest point. Strength grades indicate the amount of pressure the steel rebar can withstand, and grade and

diameter are typically presented in both imperial and metric units

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:How do steel rebars affect the seismic performance of a structure?

- Steel rebars have a significant impact on the seismic performance of a structure. The primary role of steel rebars is to reinforce concrete and enhance its strength and ductility. This reinforcement plays a crucial role in mitigating the damaging effects of seismic activity. During an earthquake, a structure experiences various forces, such as lateral forces, shear forces, and bending moments. These forces can cause the structure to deform, crack, or even collapse. However, steel rebars provide resistance against these forces and help maintain the integrity of the structure. The presence of steel rebars increases the tensile strength of concrete, which is otherwise weak in tension. This enhanced tensile strength allows the structure to better withstand the lateral movement induced by seismic waves. By distributing the forces more evenly, the rebars help to reduce the formation and propagation of cracks, limiting the potential for structural failure. Moreover, steel rebars increase the ductility of the structure. Ductility refers to the ability of a material to undergo deformation without breaking. During an earthquake, the ground shaking can cause the structure to deform and oscillate. Steel rebars allow the structure to absorb and dissipate energy, reducing the likelihood of sudden failure. This ductile behavior is crucial in earthquake-prone regions as it provides warning signs of potential structural distress, allowing occupants to evacuate safely. Furthermore, steel rebars can be strategically placed in critical areas of a structure, such as the beam-column joints, which are highly vulnerable during seismic events. The proper detailing and configuration of rebars in these areas can significantly improve the seismic performance by strengthening the connections and preventing premature failure. In summary, steel rebars play a crucial role in enhancing the seismic performance of a structure. They increase the tensile strength of concrete, improve ductility, reduce crack formation, and strengthen critical areas. These factors collectively contribute to a more resilient structure that can better withstand and absorb the forces generated during an earthquake, ultimately ensuring the safety and stability of the building and its occupants.

- Q:Can steel rebars be used in the construction of underground parking facilities?

- Yes, steel rebars can be used in the construction of underground parking facilities. Steel rebars provide reinforcement to the concrete structure, enhancing its strength and durability. They are commonly used in the construction of foundations, walls, and slabs, making them suitable for underground parking facilities where robust structural support is required.

- Q:What are the limitations of using steel rebars?

- One limitation of using steel rebars is their susceptibility to corrosion. Over time, exposure to moisture and chemicals can cause the steel rebars to rust, which weakens their structural integrity. Additionally, steel rebars are heavy and can be difficult to handle and transport, especially in large construction projects. Lastly, steel rebars have a high thermal conductivity, which can lead to temperature changes causing expansion and contraction, potentially resulting in cracks or damage to the surrounding concrete.

- Q:What are the safety considerations when handling steel rebars?

- Some safety considerations when handling steel rebars include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. It is also important to ensure that the work area is clear of obstructions and well-lit to prevent trips and falls. Proper lifting techniques should be employed to avoid strains or back injuries. Additionally, workers should be cautious of sharp edges or protrusions on the rebars and avoid placing their hands or body in direct contact with them. Regular inspection and maintenance of the rebars for any signs of damage or rust is also crucial for safety.

- Q:What is the relationship between steel structure and thread steel?

- Thread steel is usually used in embedded parts of steel structures, sometimes in civil engineering units, and sometimes in steel structural units. How to divide the owner's list?

- Q:How are steel rebars used in airport runway construction?

- Steel rebars are used in airport runway construction to reinforce the concrete and provide structural strength to the runway. They are placed within the concrete slab to prevent cracks and ensure the runway can withstand heavy loads from aircraft.

- Q:Can steel rebars be used in structures with high resistance to fatigue?

- Structures with high resistance to fatigue can utilize steel rebars. These rebars are commonly employed as reinforcement in concrete structures due to their durability and high tensile strength. They enhance the strength and support of the concrete, making it more resilient against various loads and stresses, including fatigue. Fatigue occurs when a material weakens due to repeated stress cycles, potentially causing structural failure over time. Steel rebars, particularly those made from high-strength steel, are specifically designed to withstand cyclic loading and offer exceptional resistance to fatigue. With their high fatigue strength, they can endure multiple stress cycles without significant deterioration. In structures with high fatigue resistance, engineers strategically position steel rebars to distribute and dissipate applied loads. This reduces stress concentrations and minimizes the risk of fatigue failure. The reinforcement provided by steel rebars improves the overall structural integrity and longevity of the construction. Furthermore, the use of steel rebars allows for the implementation of various design techniques, including the inclusion of additional reinforcing elements like stirrups and tie hooks. These elements further enhance the structure's resistance to fatigue. By considering these design considerations, steel rebars effectively mitigate the effects of cyclic loading and maintain the structure's stability and performance over time. However, it is important to note that the fatigue resistance of a structure does not solely rely on steel rebars. Other factors, such as the quality of concrete, proper detailing and placement of rebars, and adherence to proper construction practices, also impact the overall fatigue performance. Therefore, it is crucial to adopt a comprehensive approach that incorporates appropriate design, material selection, and construction techniques to achieve structures with high resistance to fatigue.

- Q:32 of the rebar is one meter multiple

- The raw steel billet for the production of threaded steel is carbon structural steel or low alloy structural steel which is treated by calm melting, and the finished steel bar is delivered in hot rolling forming, normalizing or hot rolling state.

- Q:Can steel rebars be welded to other steel components?

- Steel rebars have the capability to be welded to other steel components. In construction projects, welding serves as a common method for connecting steel rebars to various steel structures or components. This procedure involves heating the rebars and steel components to a high temperature, causing them to melt. Following this, they are allowed to cool and solidify, resulting in a strong and durable bond. Welding steel rebars to other steel components is widely accepted and contributes to the overall integrity and stability of the construction. By ensuring a dependable connection, it enables the rebars and steel components to effectively withstand external forces and loads. However, it is crucial to employ proper welding techniques and adhere to relevant industry standards and guidelines to guarantee a successful and safe welding process.

- Q:How can the quality of steel rebars be tested?

- To ensure the strength and reliability of steel rebars, there are various methods available for testing their quality. Some commonly used techniques include: 1. Conducting a visual inspection to identify any visible defects like surface cracks, unevenness, or corrosion that may impact performance. 2. Analyzing the chemical composition of the rebars through spectroscopy or similar methods to ensure compliance with required standards. This analysis verifies the presence and percentage of elements such as carbon, manganese, and silicon. 3. Testing the rebars' tensile strength by subjecting a sample to tension until it fractures. The maximum force applied before breaking determines the tensile strength and helps identify weak spots or inconsistencies. 4. Evaluating the ductility of rebars through a bend test, bending them to a specific angle without any signs of cracking or fracture. This ensures the rebars can withstand bending and shaping during construction without compromising their structural integrity. 5. Using ultrasonic testing to detect internal flaws or defects within the rebars. This non-destructive method helps identify hidden cracks, voids, or inclusions that could weaken the rebars. 6. Determining the hardness of the rebars using the Rockwell or Brinell hardness test. This test measures the resistance of the rebar's surface to indentation, providing insight into its strength. 7. Subjecting the rebars to corrosion resistance testing, such as salt spray testing or electrochemical methods, to assess their resistance against rust and other types of corrosion. By combining these testing methods, manufacturers, construction companies, and engineers can ensure that steel rebars meet the required quality standards and can withstand the intended load and environmental conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Deformed iron rods for construction building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords