HRB400 HRB 500 steel rebar Good quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

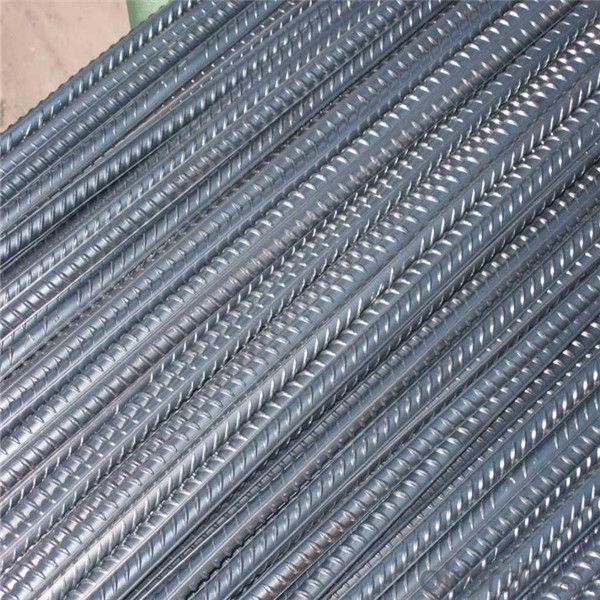

Deformed Steel bar is a common steel reinforcing bar, used in reinforced concrete and reinforced masonry structures.

It is formed from mild steel, and is given ribs for better frictional adhesion to the concrete. The Deformed Steel bar is

an iron rod , a weldable plain reinforcing steel bar, and can be used as well for steel meshes.

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

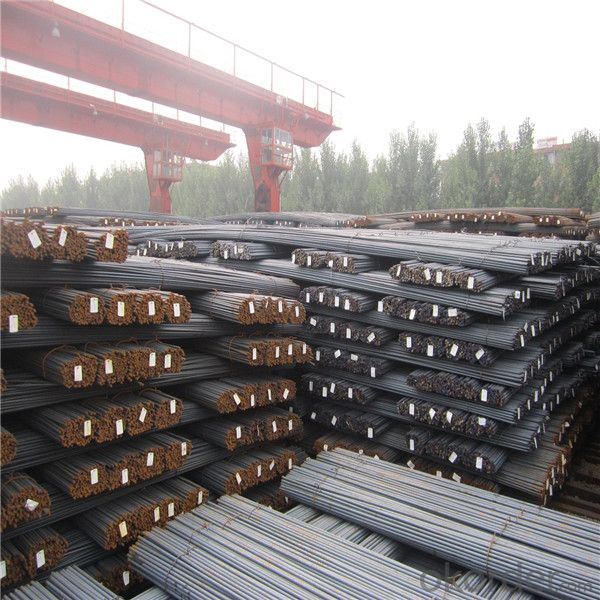

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:Can steel rebars be used in offshore oil and gas platform construction?

- Yes, steel rebars can be used in offshore oil and gas platform construction. Steel rebars are commonly used as reinforcement in concrete structures, including offshore platforms. They help to increase the strength and durability of the concrete, making it more resistant to the harsh conditions found in offshore environments such as strong winds, waves, and corrosive saltwater. The use of steel rebars in offshore platform construction ensures the structural integrity of the platform, providing a safe and reliable structure for oil and gas extraction operations. Additionally, steel rebars can be designed and manufactured to meet specific industry standards and requirements, ensuring their suitability for offshore applications.

- Q:What is the purpose of using steel rebars in concrete structures?

- The purpose of using steel rebars in concrete structures is to enhance the overall strength and durability of the structure. Concrete, while excellent in compression, is weak in tension. By incorporating steel rebars into the concrete, the structure is able to resist tensile forces and prevent cracking or failure. Steel rebars, which are typically made of carbon steel, are strong and have high tensile strength. They are placed within the concrete forms before pouring, creating a reinforced concrete structure. When subjected to tensile forces, the concrete transfers the load to the steel rebars, which can resist the pulling or stretching forces. This reinforcement helps to distribute the load more evenly, preventing localized stress points and reducing the risk of structural failure. In addition to providing tensile strength, steel rebars also help to control cracks in concrete structures. As concrete shrinks and expands due to temperature changes or drying, it is susceptible to cracking. The presence of steel rebars helps to limit the width and extent of these cracks, ensuring the structural integrity and longevity of the concrete. Furthermore, steel rebars can improve the resistance of concrete structures to seismic activity or other dynamic forces. The flexible nature of steel rebars allows them to absorb and dissipate energy during earthquakes or other vibrations, reducing the risk of collapse. Overall, the purpose of using steel rebars in concrete structures is to reinforce and strengthen the concrete, providing additional tensile strength, controlling cracks, and enhancing the overall durability and resilience of the structure.

- Q:Can steel rebars be used in modular bridges?

- Yes, steel rebars can be used in modular bridges. Steel rebars are commonly used in the construction of bridges due to their strength, durability, and ability to handle heavy loads. They provide reinforcement to the concrete components of the bridge, ensuring its structural integrity. In modular bridge construction, steel rebars are often incorporated into precast concrete elements, allowing for efficient and cost-effective assembly of the bridge modules.

- Q:What are the different types of steel rebars used in high-rise buildings?

- The different types of steel rebars commonly used in high-rise buildings include carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. These rebars have varying properties and are chosen based on factors like strength, corrosion resistance, and durability to ensure structural integrity and safety in the building's construction.

- Q:Are there any specific safety measures to be taken while working with steel rebars?

- Yes, there are several specific safety measures to be taken while working with steel rebars. These include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against cuts, eye injuries, and foot injuries. It is also important to ensure that the work area is well-lit and free from tripping hazards. Workers should be trained in proper handling techniques to avoid strains and sprains, and should never carry or drag rebars by hand. Additionally, it is crucial to use the correct tools for cutting and bending rebars and to follow safe lifting practices to prevent back injuries. Regular inspections of the rebars for damage or defects should also be conducted to maintain a safe working environment.

- Q:What is the role of steel rebars in basement wall construction?

- Steel rebars play a crucial role in basement wall construction by providing reinforcement and structural support to the concrete wall. Reinforcing bars, which are commonly made of carbon steel, are strategically positioned within the concrete prior to pouring. Their placement adds strength and stability to the wall, allowing it to withstand various external forces such as soil pressure and lateral forces. By distributing the load and forces that the wall may encounter, steel rebars prevent cracking or collapse under these pressures, ensuring the wall's durability and structural integrity. Additionally, they help control shrinkage and expansion of the concrete caused by temperature changes. By acting as a framework within the wall, the rebars limit the formation of cracks and maintain the overall stability of the structure. In summary, the inclusion of steel rebars significantly enhances the strength and durability of basement walls. They are essential for maintaining the integrity of the structure and safeguarding it against potential damage or failure.

- Q:How are steel rebars stored on construction sites?

- Steel rebars are typically stored on construction sites in a horizontal position, often on racks or pallets, to prevent bending or deformities. They are organized based on size, type, and length to facilitate easy access and efficient usage during the construction process. Additionally, rebars may be protected from corrosion by being covered with a tarp or stored in a designated area to prevent exposure to moisture and other elements.

- Q:What are the different surface finishes available for steel rebars?

- There are several surface finishes available for steel rebars, including plain, deformed, epoxy coated, galvanized, and stainless steel. Each finish offers unique properties and benefits depending on the application and environment in which the rebars will be used.

- Q:What are the different methods of reinforcing concrete structures using steel rebars?

- There are several methods of reinforcing concrete structures using steel rebars. 1. Traditional Reinforcement: This method involves placing steel rebars in the formwork before pouring concrete. The rebars are positioned in a predetermined pattern and secured with wire or tie rods to ensure they stay in place during the concrete placement. This method is commonly used for reinforcing columns, beams, and slabs. 2. Pre-stressed Reinforcement: In this method, high-strength steel rebars are pre-stressed before being placed in the concrete structure. This is usually achieved by stretching the rebars and then anchoring them to resist the tensile forces that will be exerted on the structure. Pre-stressed reinforcement is commonly used in bridges and large-span structures where high strength and durability are required. 3. Post-tensioning: Post-tensioning is a technique used to reinforce concrete structures after the concrete has hardened. It involves inserting steel tendons into pre-determined ducts or sleeves within the concrete and then applying tension to the tendons using hydraulic jacks. This process helps to counteract the tensile forces and increase the overall strength and load-carrying capacity of the structure. 4. Fiber Reinforcement: Instead of using traditional steel rebars, fiber reinforcement involves adding small fibers made of materials like glass, polypropylene, or steel to the concrete mix. These fibers help to distribute and control cracks that may occur due to shrinkage or thermal expansion. Fiber reinforcement is often used in applications such as industrial flooring, shotcrete, and precast concrete products. 5. Reinforced Concrete Masonry: In this method, steel rebars are inserted into the mortar joints of concrete masonry units (CMUs) to increase the strength and stability of the structure. The rebars are placed vertically and horizontally at specific intervals and then grouted to ensure a solid bond between the rebars and the CMUs. Overall, these different methods of reinforcing concrete structures using steel rebars provide various options for engineers and designers to enhance the strength, durability, and load-carrying capacity of concrete structures, depending on the specific requirements of the project.

- Q:Are there any environmental concerns associated with steel rebars?

- Yes, there are some environmental concerns associated with steel rebars. One of the main concerns is the production process of steel rebars, which involves the extraction and processing of iron ore. This process is energy-intensive and can contribute to greenhouse gas emissions and air pollution. Additionally, the mining of iron ore can lead to habitat destruction and the displacement of wildlife. Another environmental concern is the potential for steel rebars to corrode over time, especially in marine and coastal environments. Corrosion can lead to structural degradation, which may require replacement and additional resources and energy consumption. Furthermore, the disposal of steel rebars at the end of their lifecycle can also pose environmental challenges. If not properly managed, steel rebars can end up in landfills, taking up valuable space and potentially releasing harmful substances into the environment. However, it is important to note that steel rebars are often recycled, which can help mitigate some of these environmental concerns. Recycling steel rebars reduces the need for new production, conserves natural resources, and decreases energy consumption and greenhouse gas emissions. Additionally, the use of recycled steel rebars can help prevent the disposal of these materials in landfills. Overall, while there are environmental concerns associated with steel rebars, proper management and recycling practices can help minimize their impact on the environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HRB400 HRB 500 steel rebar Good quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19863 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords