Wooden Furniture Panel Laminating Machines

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wooden Furniture Panel Laminating Machines

Products detail

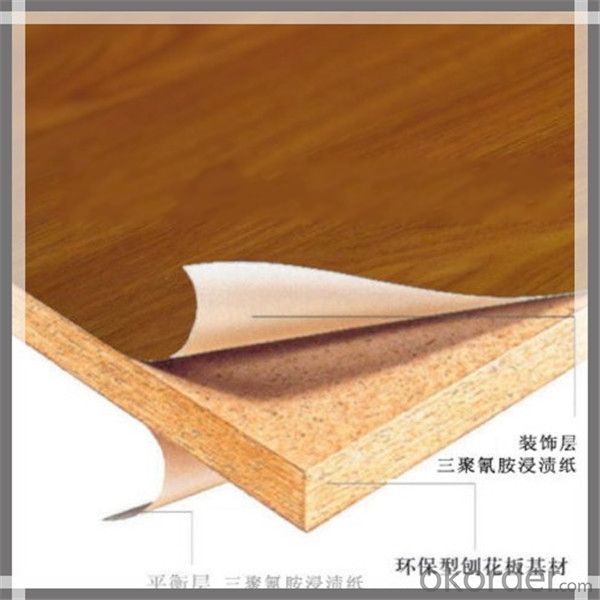

Wooden furniture panel laminating machines is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Wooden furniture panel laminating machines is availale according to your requirements!

Features

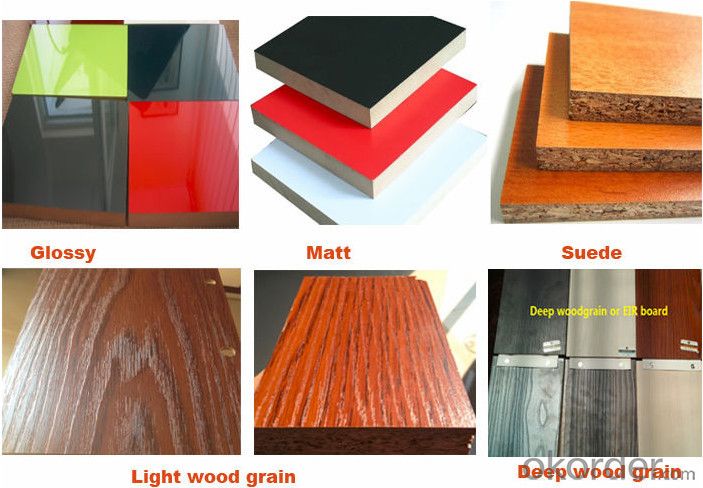

Wooden furniture panel laminating machines is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Wooden furniture panel laminating machines are for)

- Wooden furniture panel laminating machines for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

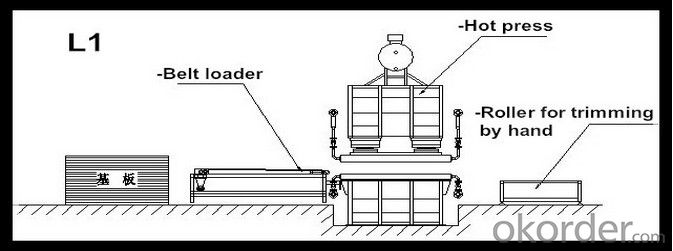

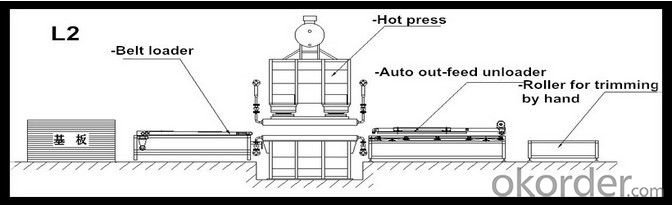

Wooden furniture panel laminating machines Production line A&B

Specification

The technical parameters of Wooden furniture panel laminating machines :

| Type | Size (ft) | Nominal Pressure (KN) | End Panel Size (mm) | Working Pressure (kg/cm2) | Main oil cylinder (Diameter×Quantity) |

| NYJ-900T | 4×8 | 9000 | 1220×2440 | ≤30 | Φ280×6 |

| NYJ-1200T | 4×8 | 12000 | 1220×2440 | ≤40 | Φ320×6 |

| NYJ-1400T | 4×8 | 14000 | 1220×2440 | ≤47 | Φ340×6 |

| 5×8 | 1550×2440 | ≤37 | Φ340×6 | ||

| 6×8 | 1830×2440 | ≤31 | Φ340×6 | ||

| NYJ-1600T | 4×8 | 16000 | 1200×2440 | ≤53 | Φ380×6 |

| 4×9 | 1200×2750 | ≤47 | Φ380×6 | ||

| 5×8 | 1500×2440 | ≤42 | Φ380×6 | ||

| 7×9 | 2100×2750 | ≤27 | Φ380×6 | ||

Products display

Packing & Shipping

Package: Wooden furniture panel laminating machines will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

Q:How to control the quality ?

A:Inform you the new progress of the production in some certain time. You will clear imagine how yourmachine made from the raw material step by step.To make sure our salesman be your eyes and ears.

The Ex-work test. The ex-work including the Final assembly test, factory test and working performance test. Each machine no matter big or small must pass the Ex-work work before leaving the factory. We must gurantee everyone machine from CNBM workshop must be qualified . The vedio will be taken for the test, and welcome you to come to our factory for inspection.

Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q:So I just recently discovered what loose eyeshadow (pigments) are and they do seem to give off an amazing vibrant colour. However, I've been thinking can you still get the same vibrant colour with a really good cream eyeshadow as a base (over primer) and then pressed eyeshadow on top?I've been thinking about getting NYX loose pearl eyeshadows however, the thing is I have a lot of pressed eyeshadow palettes already. So, I've been wondering if I were to buy a good cream eyeshadow, such as Maybelline Color Tattoo and use that as a base before applying the pressed eyeshadow, would I get vibrant colour as well?I've been reading up reviews and I think it does the same thing however, I'm unsure. Also, are loose eyeshadows (when applied with medium) as easy to blend as pressed eyeshadows are?Any help is appreciated. Thanks.

- Pressed eyeshadow is better . If you apply a good eyeshadow primer , pressed eyeshadow gives same effect . Loose eyshadow (pigment) are good for special occasion not for everyday . Apply cream eyeshadow dab pressed eyeshadow to give vibrant effect :)

- Q:Is the Leg press a good way to build leg strength, as an Offensive lineman would need? Or is squat better?

- Squats work every muscle in your body, from your lats and upper back, all the way down through your hips and thighs. Quite simply, this one lift will recruit and develop your entire body. Maybe even more importantly, it will teach your body to work as a well-oiled, functional unit. When training, I tend to avoid the leg press machine. Instead, try front/back squats, dead lifts and Bulgarian split squats.

- Q:i have installed windows vista, unknowingly i changed the active boot option from 'C' drive to some other drive.now my lap doesnt boot and shows BootMGR missing, Press ctrl+alt+del to restart and also not even open the BIOS setup window.usually i install the OS by using USB Flash drive(since CD drive not working).(Laptop Model : compaq presario C700)How to recover this problem. Please help me....,Thanks in advance

- press ctrl alt delete and then press escape and do a factory image restore

- Q:Im Looking for a high end pressed powder ( so no drugstore pressed powders) and i have combination to oily skin... any suggestions??!!

- If you want MAC quality on a 'drug store' budget, I'd suggest getting Ben Nye pressed powder. It has just as much pigment as MAC for half the price.

- Q:What are the benefits/results of both of these bench press'?As i'm not quite sure which one to do.

- Flat is for chest and Incline is more for shoulders

- Q:if the recipe calls for a cookie press, and i dont have one, do i have to have it in order to still make the cookies?what does it do? please answer both

- no you don't it is only for looks. you can shape the dough in balls and press them either with a fork or a flat bottomed glass dipped in sugar so it does not stick.

- Q:Ok I will be 16 in March here(today is 2/16/09), I'm 5'11-6'0(somewhere between there) and weigh 161 ilbs and I can bench press 185 ilbs.

- Three things that need to be taken into consideration your age, height, and body type, not given. 161 lbs is not bad if there is no fat involved. However, if you are trying to get rid ofbaby fat it is best that you press lighter weights doing more reps so as to burn fat.

- Q:so this girl and I got into a conflict and I got taken out by the cops, moments after that the girls mom comes over to me and starts cursing at me and calling me all these names screaming in my face, and she brought my family into it and my friends, I have my friends who where there when she came over to me. can I press charges? she also like sorta touched me but she didn't hit me but she kept getting in my face

- No, you could try harrassment but ud probably not win it in court : sorry

- Q:91 jeep wrangler dont have ball joint press

- autozone, advance auto, i think napa will loan you one

- Q:How long do pressed flowers last without them falling apart? I bought pressed flowers from a brand called Pressed Petals, but don't know how long they'll last. Would they last at least a year or two?

- first you have to remove the flowers from the bouqet and cutoff the stalks upto half inch of each and every flower and branch and now keep in fresh watered flowervase and also you have to change the water every day . And also check the stalks or stems everyday if they develop any change in its orijinal colour you have to cutoffagain upto half inch as I told before.This keeps your flowers last longtime. you can press the flowers by keeping them between the pages of a book ,but you have to change the flower every day from that page to another. However it takes much time if you want to do it quickly you can press it by keeping hot iron box of it but not directly but you have to put between the two pages and then iron it without much heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wooden Furniture Panel Laminating Machines

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products