Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

1. Detailed Specifications:

| Product | Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application:

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

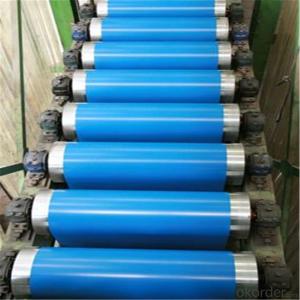

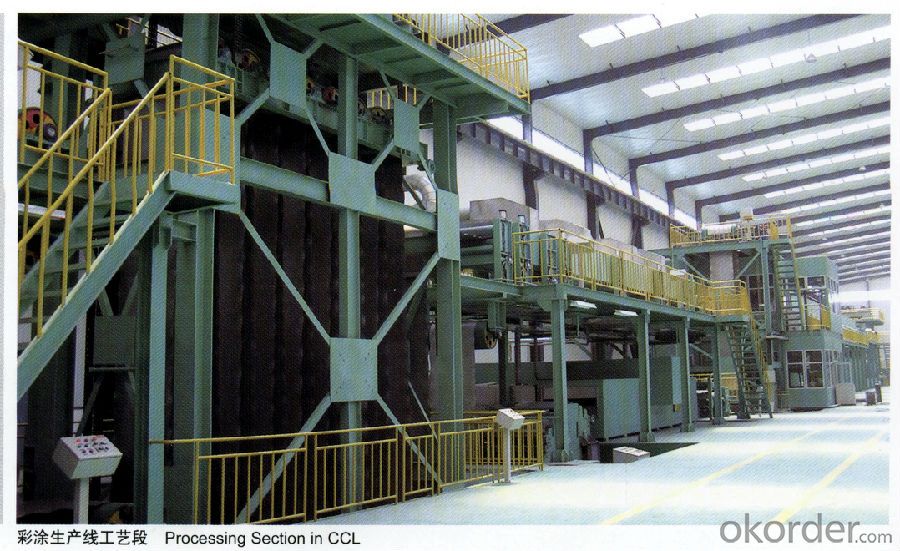

3. Image:

production Line:

production show:

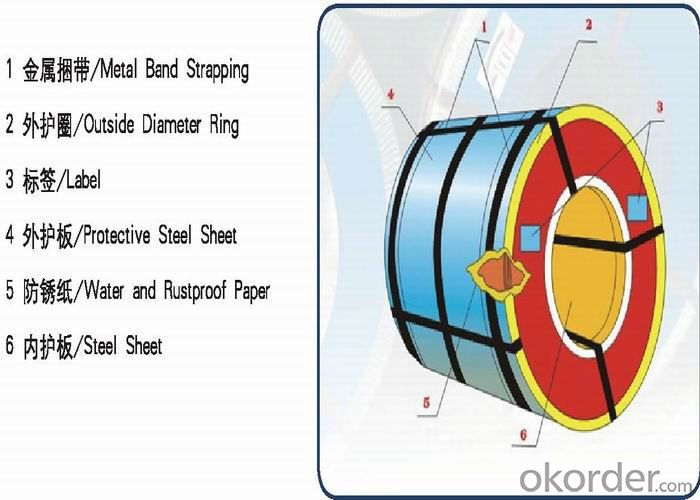

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q:I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- Carbon steel chef's knives out perform stainless in every aspect except 1, care. You can't put them in a dishwasher. Wash, rinse and dry off. Do not keep them in a drawer filled with other kitchen stuff, rather, keep them in a cabinet or block. If it starts to rust you can use steel wool to clean them up, or fine grit sandpaper if you want to retain a fine finish. For your viewing pleasure, a chef's knife I forged from crane cable.

- Q:How are steel coils inspected for hardness using hardness testers?

- To assess the strength and durability of steel coils, hardness testers are employed to examine their hardness. Hardness testers are specialized devices used to gauge a material's resistance to indentation or penetration. For steel coils, Rockwell or Brinell testers are commonly utilized. Both methods entail exerting a precise force onto the surface of the coil and measuring the depth of indentation or size of the impression made. In the case of Rockwell testing, a steel ball or diamond cone is pressed onto the coil's surface with a predetermined force. The depth of penetration is then measured and compared to a standardized scale in order to determine the hardness value. Different scales are employed based on the size and type of indenter in use. On the other hand, Brinell testing involves using a spherical indenter made of tungsten carbide or hardened steel. This indenter is pressed onto the coil's surface with a known force, and the resulting indentation is measured and compared to a standardized table to determine the hardness value. Both methods provide a quantitative measure of the steel coil's hardness, which serves as an indicator of its ability to resist deformation, wear, and cracking. The hardness test results are subsequently utilized to ensure that the steel meets specific quality standards or customer requirements. It is important to note that the inspection process may involve sampling, where representative sections of the steel coil are tested, or it may involve testing the entire coil, depending on the specific inspection requirements. Additionally, accurate and reliable results necessitate proper calibration and maintenance of the hardness testers.

- Q:What are the common problems encountered with steel coils during production?

- There are several common problems encountered with steel coils during production. One of the most common issues is coil slippage, where the coils shift or slide out of place during handling or transportation. This can result in damage to the coils or pose a safety risk to workers. Another common problem is coil rusting or corrosion. Steel coils are susceptible to rusting if they come into contact with moisture or are not properly protected. Rust can compromise the structural integrity of the coils and lead to product defects or failure. Coil breakage is also a common problem. This occurs when the coils are subjected to excessive stress or tension, causing them to crack or break. Coil breakage can result from improper handling or storage, as well as production issues such as improper rolling or cooling processes. Coil surface defects are another common issue. These defects can include scratches, dents, or uneven surfaces on the coils. Surface defects can compromise the appearance and quality of the final product, making it unsuitable for certain applications. Lastly, coil contamination is a problem that can occur during production. Contaminants such as dirt, oil, or foreign particles can adhere to the surface of the coils, leading to quality issues or difficulties in further processing. Contamination can result from improper handling, inadequate cleaning processes, or poor environmental control. To mitigate these common problems, proper handling and storage practices are essential. This includes using appropriate lifting and transporting equipment, ensuring the coils are stored in a dry and clean environment, and implementing effective rust prevention measures. Regular inspections and quality control checks can also help identify and address any issues early on, preventing further damage and ensuring the production of high-quality steel coils.

- Q:Hi I was thinking about buying this knife, but i wasn't sure if it was good because it's stainless steel.

- This isn't really a question for this section, but I'm still happy to help out since I'm a big cutlery nerd as well. One thing to look out for when buying a knife is a lack of specifics on what steel is being used. High Carbon Stainless Steel doesn't tell you what the steel is, just what it MIGHT be. Chances are it's something along the lines of 420HC or 440A, both of which are softer steels. They aren't the worst steels around, but they are very quick to dull. You'd be better off looking at the Balisongs of Benchmade. They'll cost more, but you'll know that you're getting something made with quality materials and that won't break on you. And if it does break for some odd reason, Benchmade's warranty and customer service are both fantastic. Although if a more questionable knife is okay with you as long as the price isn't too high, then at least 420HC and 440A aren't too brittle and will take a decent edge even though they'll dull quickly. As for whether stainless steel is good for a knife or not, that depends on the type of stainless steel and what you're going to use the knife for. Many stainless steels are more brittle than a carbon steel, so high carbon stainless steels are a bit more likely to rust but a little tougher as well. In a butterfly knife, a steel like that is a good way to go, although the steels used by Benchmade, as I mentioned, are of a much better quality.

- Q:How do you prevent damage to steel coils during transportation?

- To prevent damage during the transportation of steel coils, there are several measures that can be taken: 1. Tight and secure packaging: It is important to pack the steel coils tightly and securely to prevent any movement or shifting during transportation. This can be achieved by using appropriate packaging materials such as steel cradles, wooden dunnage, or steel straps to hold the coils in place. 2. Use cushioning materials: Adding cushioning materials like foam padding, cardboard, or bubble wrap between the coils can help absorb shocks and vibrations during transit. This additional layer of protection minimizes the risk of scratches, dents, or other damages caused by contact with other objects or surfaces. 3. Handle and load properly: It is crucial to use proper lifting equipment and techniques to avoid mishandling and dropping of the steel coils. Carefully lifting and loading the coils onto transportation vehicles using forklifts or cranes is recommended. Additionally, stacking the coils in a way that distributes weight evenly helps maintain stability. 4. Protect from weather: Steel coils are susceptible to corrosion, so it is essential to shield them from moisture and adverse weather conditions during transportation. Covering the coils with waterproof and weather-resistant tarps or shrink wrap prevents water or moisture from reaching the steel surfaces. 5. Regular inspections: Conducting regular inspections before, during, and after transportation is vital to identify any potential damage or issues. This allows for timely intervention to rectify any problems and prevent further damage. 6. Trained personnel: It is crucial to ensure that personnel involved in handling, loading, and transporting the steel coils are properly trained. They should be knowledgeable about the correct procedures and techniques to safely handle and transport the coils, reducing the risk of damage. By implementing these preventive measures, the likelihood of damage to steel coils during transportation can be significantly reduced, ensuring that the coils reach their destination in optimal condition.

- Q:i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q:What are the different methods of coil flattening for steel coils?

- There are several methods used for coil flattening in the steel industry. Some of the common methods include roller leveling, tension leveling, and stretcher leveling. Roller leveling involves passing the coil through a series of rollers to flatten it. Tension leveling uses a combination of tension and bending to remove any shape defects in the coil. Stretcher leveling stretches the coil in the lengthwise direction to eliminate any waviness or buckling. Each method has its own advantages and is used based on the specific requirements of the steel coil.

- Q:How do steel coils contribute to corrosion resistance in products?

- Steel coils contribute to corrosion resistance in products through a combination of factors. Firstly, steel coils are often made from stainless steel, which contains a high amount of chromium. Chromium forms a protective oxide layer on the surface of the steel, known as a passive film, which acts as a barrier against corrosion. This passive film is self-healing, meaning that if it gets damaged or scratched, it can regenerate itself, ensuring continued protection against corrosion. Additionally, steel coils undergo a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc layer acts as a sacrificial anode, meaning that it will corrode preferentially to the steel. This sacrificial corrosion protects the steel underneath, effectively preventing rust and other forms of corrosion from developing. Moreover, steel coils can be coated with various protective coatings, such as epoxy or polyurethane, to further enhance their corrosion resistance. These coatings provide an additional physical barrier that prevents moisture, chemicals, and other corrosive elements from reaching the steel surface. Lastly, steel coils can be manufactured with specific alloying elements, such as nickel or molybdenum, which further improve their resistance to corrosion. These alloying elements enhance the strength and durability of the steel, making it better able to withstand corrosive environments. Overall, steel coils contribute to corrosion resistance in products by utilizing stainless steel, galvanization, protective coatings, and alloying elements. By implementing these measures, steel coils ensure that products maintain their structural integrity and appearance over time, even in harsh and corrosive conditions.

- Q:Are steel-capped boots safer than non-capped ones when working with horses? I have been told that sometimes if a horse steps on you, the steel crushing into your foot is more dangerous than if you just had normal wellies on, as at least with normal wellies there is some flexibility. Any horsey people out there got any experience with this? Thanks!

- Having had horses tap-dance on my toes while I was wearing normal leather boots, resulting in loss of toenails every now and then, I gotta say that steel-toed boots sound like an awfully good idea.

- Q:What are the different methods of coil rewinding for steel coils?

- Coil rewinding for steel coils can be approached in various ways, each with its own merits and considerations. One frequently employed technique is the slitting and rewinding process. This entails slicing the original steel coil into narrower strips, commonly known as "slits," and then winding these slits onto separate reels. Slitting and rewinding grants the ability to customize the width of the coil, making it popular in industries like automotive, construction, and packaging. Another method is oscillate winding. This approach involves rewinding the steel coil in a back-and-forth manner, resulting in a tighter and more compact coil. Oscillate winding proves particularly advantageous in reducing coil deformation during transportation and storage, as well as optimizing material usage. Additionally, the pancake coil winding method finds frequent use for steel coils. This technique involves rewinding the steel coil in a flat, pancake-like shape, making it easier to process and handle. Pancake coils are often employed in applications where space is limited, such as electrical transformers. Furthermore, advanced coil rewinding methods make use of automated equipment, such as robotic systems or computer-controlled winding machines. These technologies ensure precise and consistent rewinding, minimizing human error and enhancing overall efficiency. Ultimately, the choice of coil rewinding method hinges on the specific requirements of the application, including coil dimensions, material properties, and desired production output. Manufacturers must thoughtfully consider factors like coil quality, cost-effectiveness, and equipment capabilities when deciding on the most suitable method for their steel coil rewinding process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords