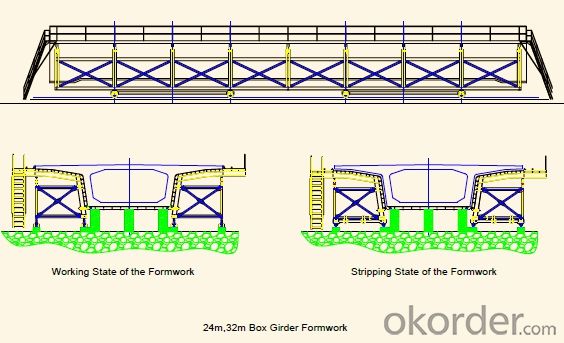

Wholely Assembled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BOX GIRDER

External formwork of 32/24 meters post-tensioning concrete pre-faricated box girder is divided into sliding mode and

rolling mode; the side form of the first mode can move from one bottom form to the other one which increases the

utilization rate, and decrease the investment for the formwork during construction; the side form of the second mode

is relatively fixed according to the bottom form, and could be dismantled by revolving, which improve the efficiency

of formwork closure.The side formwork unit is mainly 6 meters, the design of the sructure is compact

and reasonable with beautiful and smooth appearance.

Features

■ All the edges of ecternal formwork panels for the box girder have been milled, which ensure

the assembly precision to avoid the leakage of the concrete

■ The bottom formwork unit is 3 meters to facilitate the installation and anti-arch adjustment

■ The bulkhead is designed to envelop the sideform,which can be wholely assembled, making the removal, installation and adjustment much easier.

- Q:What is the wire mesh in front of the foundation beam

- Beams are reinforced, how to put into the template? How can we ensure that the concrete does not flow out? Wire netting is the best way

- Q:What is the demolition order of the construction template

- 3 the demolition of multilayer floor pillar shall be carried out according to the following requirements: when the upper floor slab is pouring concrete, the next floor slabThe pillar shall not be removed, then the next floor of a live, can only be removed part of the span is 4M or above 4M Xiajun should retain the brace beam, pillar spacing shall not be greater than 3M.

- Q:When Liang Banzhong beam template calculation is the calculation of him in the board? Because in the calculation of engineering quantity of concrete beam by beam plate calculation. But when the template is, the book is not clear. In the calculation of the time quota template can have a beam plate.I use the Guizhou 04 quotaEspecially your last sentence, I haven't said anything yet,There is the Guizhou 04 fixed and did not say what sub beam frame beam separationAbove the beam plate is to explain the main beam, sub beam and plate, according to the calculation of beam and plate volumeThen you explain to me the frame beam is not the main beam? According to this explanation, why do you separate the frame beam

- There are beams and plates in the plate with a secondary beam, the frame beam can not be calculated, in the calculation, the plate and the secondary beam of the amount of work together, are the implementation of beam and plate

- Q:How to calculate the length of the beam, beam template area

- This is the case: (7800-600) * (800*2+400) forgot, 800 also minus plate thickness

- Q:The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- The ground beam (patand) agreement is commonly known as the foundation beam, which has the characteristics of closed, and the structure of the column into a seismic system,

- Q:Which part of the middle beam and side beam in the T beam template? Thank you

- The use of T beam highway bridge generally 5 pieces of beam for the span of 1, which is the outermost of the two to become [edge beam]

- Q:More than the number of square cross-section of the beam high formwork

- The above construction total load of more than 10kN/m2, or concentrated line load greater than 15kN/m template support system that belongs to the template, if you do not consider other loads, considering the single weight, according to concrete 25000KG/m3 calculation, then the beam section area of 0.4m2 belongs to the template, such as 400*1000, 300*1350, 500*800 etc.. Central line loads can be calculated in similar ways. Copy paste..

- Q:How to put the beam formwork in concrete structure

- By way of hanging on the board, you do not want to put a line for you!

- Q:Beam column plate template how to calculate the need to deduct what part?

- The second is to calculate the template of the beam to calculate the template of the beam with the section length multiplied by the length of the unit is M2Finally the board notice when calculate the template template amount is peripheral template must take and post together part to deduct the intersection with beam part to be deducted

- Q:What is the formula of beam slab formwork

- Rectangle, F=1, A is the length of the bottom edge, B is high.....So, S1S2, S3,..., one by one.The sum of the above Si is the total area. The amount of template engineering is required.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholely Assembled Box Girder Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords