Waterproof Safe Single - Side Climbing Formwork For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

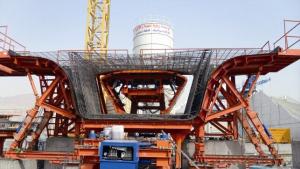

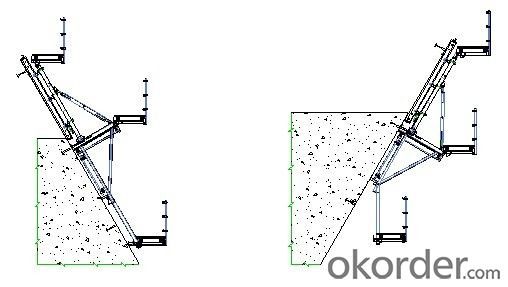

1. Structure of Waterproof Safe Single - Side Climbing Formwork For Wall

With CMAX SCB180 climbing systems, the loads from the fresh concrete pressure are transferred through the brackets by means of V-strong backs and compression braces into the scaffold anchors.

Typical applications for the SCB 180 system are dams, locks, cooling towers, pier heads, tunnels, and bank vaults.

The formwork is simply tilted backwards when striking takes place. The 1.80 m wide bracket requires only a minimum of space.

2. Main Features of Waterproof Safe Single - Side Climbing Formwork For Wall

A) Economical and safe anchoring

The M30/D20 climbing cones have been designed especially for single-sided concreting using SCB180 in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

B) Stable and cost-effective for high loads.

Generous bracket spacing allow large-area formwork units with optimal utilization of the bearing capacity. This leads to extremely economical solutions.

C) Simple and flexible planning

With SCB180 single-sided climbing formwork, circular structures can also be concreted without undergoing any large planning process. Even use on inclined walls is feasible without any special measures because additional concrete loads or lifting forces can be safely transferred into the structure.

D) It is with the advantages of standard design, excellent applicability and interchangeable.

3. Waterproof Safe Single - Side Climbing Formwork For Wall Images

4. Waterproof Safe Single - Side Climbing Formwork For Wall Specification

5. FAQ of Waterproof Safe Single - Side Climbing Formwork For Wall

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Waterproof Safe Single - Side Climbing Formwork For Wall, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of TWaterproof Safe Single - Side Climbing Formwork For Wall, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:What is the wire mesh in front of the foundation beam

- Wood can be used, but the surface is relatively smooth, after pouring, the bond will be worse; in this way, the construction is more convenient, leaving the rough concrete surface.

- Q:What is the demolition order of the construction template

- 1 demolition vertical face template, should be carried out from top to bottom; demolition of the larger span of the beam pillar, should start from the middle, respectively, to the two ends.2 demolition of beams and floor bottom mold, should loosen the wedge or lower bracket, then by block or patch removal

- Q:What kind of frame beam formwork

- Frame beam template, single beam, continuous beam template section, beam set beam template in the middle section.

- Q:I would like to ask the template support system Liang Xiaoliang Ban Xiaoliang refers to what

- Plate is a template, bamboo plywood, wood plywood. The small beam is directly supporting formwork wood architrave, there are several kinds of pine, the section size of 30 x 80, 40 x 80, 50 x 100. Support is wood brace steel bar, also called beam

- Q:How to calculate the length of the beam, beam template area

- The two cross KL76, distance of each cross axis of the pillar width is Jingchang (beam by beam, high *2+ Liang Kuan)

- Q:How to support 6m arc beam template how to set up?

- If you use a supporting beam of radian template, the bottom surface made of a whole block template (template block with good reinforcement, pouring backwater) after dismantling the entire arc shape template on the line; if the second half of the same radian can do a whole half arc template do the bottom die.

- Q:Known length of 50.8 meters, known to be designed for the width of the area of the loss of 1 x 0.25, I have calculated the base cap,. {1.0 * 0.25 + [0.37 + 1 x 0.1 / 2 + 0.47 * 0.1] on the bottom and bottom formula is multiplied by the divided by two. So how to calculate the foundation beam. Formwork and cushion,

- Calculation of foundation beam! When the cap is to be deducted beam

- Q:Which part of the middle beam and side beam in the T beam template? Thank you

- So there are [side span beam], [cross the middle beam], [medium span beam], [across the edge beam] four kinds of distinction. The amount of concrete, steel is a little different

- Q:How to do the foundation beam template

- The main construction method by a formwork one-time-concreting organization construction, wall, column and beam plates without construction joints, each layer of wall, column, beam plate model, a branch of Qi, while pouring concrete.

- Q:For example, a beam 200*400, length 5000Plate thickness 1005000*5000The area of the template is1, (0.2+0.3*2) *5+5*52, 0.3*2*5+5*5Which is right

- Plate side mode *2 is the circumference of the board (minus column protruding part) multiplied by the thickness of the plate 0.1M

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Safe Single - Side Climbing Formwork For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords