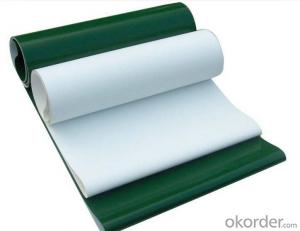

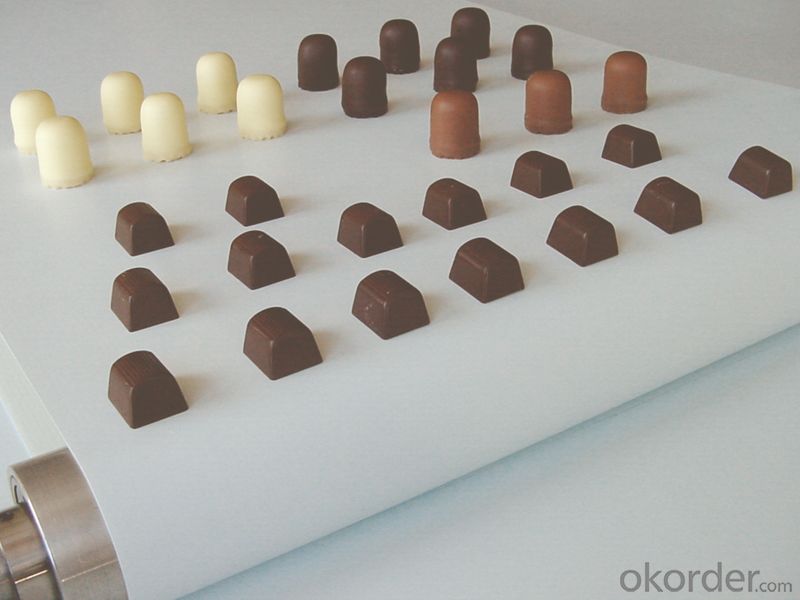

White Food Grade PVC PU Conveyor Belt 1.6mm 1.8mm 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Food Grade PVC PU Conveyor Belt 1.6mm 1.8mm 2.0mm

PVC conveyor belt,PU conveyor belt

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Product pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Can I marinate salted eggs with a plastic bucket?

- In addition, PVC plastic products at higher temperatures, such as 50 degrees or so, will slowly decompose hydrogen chloride gas, this gas harmful to humans, so PVC products should not be used as food packaging. Bakelite (bakelite) containing phenol and formaldehyde, have certain toxicity to the human body, is not suitable for the storage of food and food packaging. Electric jade (urine aldehyde plastic) although odorless, but at 100 degrees of boiling water or vinegar for containing food, there will be precipitation of free formaldehyde, harmful to the human body, so it is not suitable for food or food packaging. Waste plastics (some may add a little new material) update, because of its complex composition, it is difficult to guarantee that no toxicity, it is generally not used as food containers and packaging.

- Q:Can olive nets be used in regions with a high bird population?

- Yes, olive nets can be used in regions with a high bird population. Olive nets are specifically designed to protect olive trees from birds, preventing them from damaging the fruit. These nets are tightly woven and durable, making it difficult for birds to access the olives. Additionally, olive nets can be installed in a way that minimizes bird entanglement or injury. However, it is important to regularly monitor the nets and take necessary measures to ensure birds are not harmed or trapped.

- Q:Can olive nets be used in regions with limited access to machinery for mechanical harvesting?

- Yes, olive nets can be used in regions with limited access to machinery for mechanical harvesting. Olive nets are a traditional and manual method of harvesting olives that have been used for centuries. They involve spreading nets beneath the olive trees and manually shaking the branches to make the olives fall onto the nets. This method does not require any machinery and can be done by hand, making it suitable for regions with limited access to mechanical harvesting equipment.

- Q:Can olive nets be used to improve the profitability of olive farming?

- Yes, olive nets can be used to improve the profitability of olive farming. Olive nets are designed to protect the olives from pests, birds, and harsh weather conditions, thereby reducing crop loss and increasing the overall yield. By preventing damage to the olives, farmers can harvest a greater quantity of high-quality olives, which can then be used for various purposes such as olive oil production or table olives. This increased yield and improved quality can lead to higher profits for olive farmers, making olive nets a valuable investment.

- Q:Can olive nets be used in areas with heavy rainfall?

- Yes, olive nets can be used in areas with heavy rainfall. Olive nets are designed to protect the olives from birds and other pests, as well as to collect the fallen olives during harvesting. They are made from durable materials that can withstand different weather conditions, including heavy rainfall. However, it is important to ensure proper installation and maintenance of the nets to prevent any damage or water accumulation that could affect their effectiveness.

- Q:How does an olive net work?

- An olive net works by being spread out underneath olive trees to catch the falling olives during harvest. The netting prevents the olives from touching the ground, keeping them clean and undamaged. Once the olives fall onto the net, they can be easily collected and removed, making the harvesting process more efficient.

- Q:How do olive nets help in reducing the risk of water stress?

- Olive nets help in reducing the risk of water stress by providing shade and reducing evaporation from the soil surface. They act as a barrier, preventing direct sunlight from reaching the soil and plants, thus reducing water loss through evaporation. Additionally, olive nets help to maintain soil moisture by preventing wind from drying out the soil. This helps to conserve water and ensure that it is available for the olive trees, reducing the risk of water stress.

- Q:Can olive nets be used in regions with limited access to water resources?

- Yes, olive nets can be used in regions with limited access to water resources. Olive trees are known for their ability to withstand drought conditions, requiring less water compared to many other crops. Additionally, the use of olive nets helps to retain soil moisture and reduce evaporation, making them suitable for regions with limited water availability.

- Q:How do you determine the optimal time to install olive nets for harvesting?

- The optimal time to install olive nets for harvesting can be determined by considering the ripeness of the olives. This can be assessed by observing the color change of the olives from green to black or purple, as well as their firmness. Additionally, monitoring the sugar content and taste can also help determine when the olives are at their best for harvesting. Consulting with local agricultural experts or experienced olive growers in the specific region can provide valuable insights and recommendations on the ideal timing for installing the nets to ensure a successful harvest.

- Q:What are the benefits of plastic bags? What's the disadvantage?

- Advantages of plastic bags: the invention of plastic bags brings convenience and sanitary life for human beings. The emergence of plastic bags will also reduce food waste, the nature of the fungusproof mold also protected the health of human beings, plastic bags are used instead of other packaging materials such as paper, glass, cans, etc., to reduce energy loss;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Food Grade PVC PU Conveyor Belt 1.6mm 1.8mm 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords