Water Treatment Liquid Amino Trimethylene Phosphonic Acid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

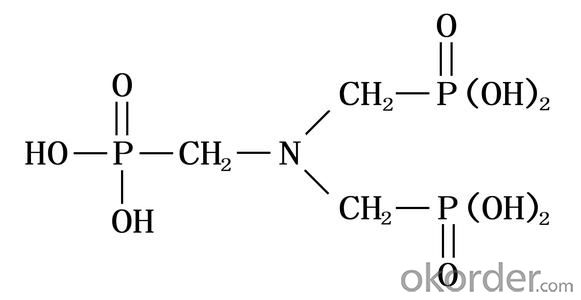

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q:In chemistry what is a catalyst and an example?

- A catalyst is a liquid or a gas you can add to a substance to make it react quicker and/or upon itself or another chemical. A catalyst can be one chemical you add to another that causes a significant reaction or they could be variables in an experiment (like temperature) can be a catalyst. It could also be a liquid/gas that you add to a substance to neutralize it or make it safe to clean/touch/handle. For instance if you spill chemicals in a biology lab, you have to add a catalyst (generally water or clarifying soap) to make it safe to clean up. Hope I could help.

- Q:What is the chemical nature of the enzyme?

- Enzyme protein and cofactor are present in the absence of catalytic activity, only these two parts together to form a complex to show the catalytic activity of this complex called the whole enzyme. Some enzymes cofactor is the metal ion, some enzyme cofactor is Organic small molecules in these organic small molecules, where the enzyme and protein binding is called the auxiliary base; and with the enzyme protein binding was more relaxed, dialysis can be used to separate the enzyme protein is called coenzyme. There is no strict boundary between the base and the coenzyme, the role of the metal ion in the enzyme molecule, or as a component of the active site of the enzyme, or the conformation necessary to form the center of the enzyme, or between the enzyme and the substrate The same coenzyme is often able to bind to a variety of different enzyme proteins, the composition of a variety of catalytic functions of different enzymes, such as coenzyme Ⅰ (NAD +) can be a variety of enzymes, As a coenzyme for many dehydrogenases, but each enzyme protein can only bind to a specific coenzyme into a whole enzyme.It can be seen that the specificity of the enzyme is the enzyme protein part of the coenzyme in the enzymatic reaction is usually responsible for electrons, atoms Or some chemical groups to determine the nature of the reaction.In recent years, it has been found that, in addition to proteins, some RNA and DNA molecules also have a catalytic effect on the chemical nature of the enzyme is the concept of protein produced a strong impact . However, the now known enzymes are essentially protein-based, or protein-dominated core components, and the concept that the enzyme is a protein-based biocatalyst does not exclude the presence of other types of catalysts, and more precisely, Can be given to the enzyme under the definition of: the enzyme is a kind of biological activity and special space conformation of biological macromolecules, including protein and nucleic acid.

- Q:Does the nature and quality of the catalyst itself change before and after the chemical reaction?

- A catalyst will induce a chemical reaction to change, leaving the chemical reaction faster or less

- Q:What is the superiority of the catalyst compared to the stoichiometric reagent?

- Activity adjustable: including inhibitors and activator regulation, feedback inhibition regulation, covalent modification and allosteric regulation.

- Q:Exemplify the use of green catalysts in green chemistry

- How can a green catalyst, they do not react

- Q:the heterogenous catalyst ZSM-5 IS used to convert ?

- Zeolite-based heterogeneous catalysts are used by industrial chemical companies in the interconversion of hydrocarbons and the alkylation of aromatic compounds. A very good example is the zeolite ZSM-5. This zeolite, developed by Mobil Oil, is an aluminosilicate zeolite with a high silica and low alumininum content. Its structure is based on channels with insecting tunnels. The aluminium sites are very acidic. The substitution of Al3+in place of the tetrahedral Si4+ silca requires the presence of an added postive charge. When this is H+, the acidity of the zeolite is very high. The reaction and catalysis chemistry of the ZSM-5 is due to this acidity. The ZSM-5 zeolite catalyst is used in the petroleum industry for hydrocarbon interconversion. An example use is in the isomerizations of xylene- from meta to para-xylene. The acidic zeolite promotes carbocation isomerizations. There are two suggested mechanisms for this type of isomerizations. Firstly shape may play a role. Perhaps para-xylene has a shape which allows it to diffuse rapidly through the zeolite structure, whereas as meta-xylene takes longer to pass through the zeolite and thus has more opportunity to be converted into the para-xylene. Secondly, is that the orientation of reactive intermediates within the zeolite channels favors specifically para-xylene.

- Q:what is a catalyst?

- A catalyst is a substance that increase the rate of chemical reaction without itself undergoing any permanent chemical changeb

- Q:Now, i am studying for my biology exam in 3 weeks time...i stumbled upon catalase, and then checked my book its catalyst...now im confused...is there a different among these 2 terms? i think..catalyst is the when a substance brings up or about a chemical reaction without using itself up and then catalase breaks down the toxic by-product of metabolism, hydrogen peroxide, into water and oxygen.Or am i wrong?please explain what is catalyst and catalase in biology or are they the same, just differently?

- an enzyme that decomposes hydrogen peroxide into oxygen and water.a substance that causes or accelerates a chemical reaction without itself being affected. To put thing simply, a catalyst is any substance that speeds up a chemical reaction. These can be natural or manmade. Catalase is actually a specific type of naturally-occuring catalyst, an enzyme in cells that decomposes hydrogen peroxide (Which is extremely toxic to life!) into harmless components. Catalase enzymes are highly concentrated in the aptly named cell organelles known as peroxisomes. Just remember- if the word ends in -ase, it's a type of enzyme! :) Hope this information helps!

- Q:pls give one or two catalysts that are used in the industry for example:Rhodium catalyst in a catalytic converter of a car or the Iron catalyst for making ammoniaTHANKS :)

- u . s . a . of america has an excellent style of organic gas. In theory that's accessible to have an electric powered motor force a compressor to take the low stress gas to make it dense adequate to get adequate interior the vehicle to run for a mutually as (in actuality, gas stations with organic gas pumps do it precisely like that, that's no longer trucked to them, we've a pair in Dallas) the real undertaking is that, specific it will be pressurized, requiring a greater perfect tank than propane, that's a liquid interior the tank, and the tank must be a cumbersome cylinder for capability or numerous smaller cylinders area by making use of area. Getting this into the physique of the vehicle devoid of doing away with all the storage/bags area isn't ordinary. And ultimate efforts nevertheless finally end up with the miles in line with fill up being decrease than the gas which inserts in a small area.

- Q:and can you give me an example of it .. please give it in easy terms if you can. thanks

- A okorder /... hope this helps!!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Water Treatment Liquid Amino Trimethylene Phosphonic Acid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products