Tower Cranes Model Self Raising Electric QTZ40( 5008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QTZ40( 5008) Description

Feature: Tower Crane Condition: New

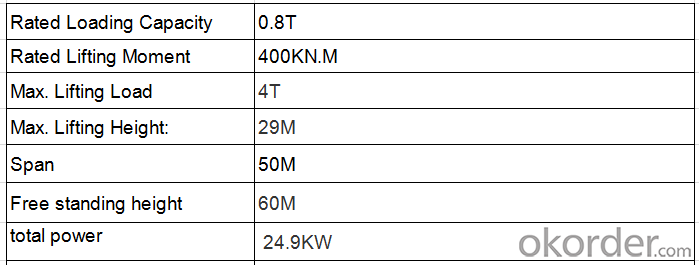

Application: urban construction Rated Loading Capacity: 0.8T

Rated Lifting Moment:400KN.M Max. Lifting Load: 4T

Max. Lifting Height:29M Span: 50M

Model Number:QTZ40( 5008)

Certification: ISO9001:2000; CE;Ukraine & Belarus Certificate

Colour: Orange/ Yellow

After-sales Service Provided: Overseas third-party support available

QTZ40( 5008) Features

1.Ten years of experience in supplying new self-erecting tower crane with Taiwo Brand.

2. Export to more than 20 countries with CE/ISO/GOST Certificates.

3. Stationary/Travelling, external/ internal climbing tower crane

4. Impeller blasting/rust protection paint

5. Advanced painting process

6. Potain masts designed with dismountable panels, making teansport easier and cheaper.

7. New designed mast, can be used to Internal and external climbing tower crane

8. Engineers available to service machinery overseas.

QTZ40( 5008) Specification

QTZ40( 5008) Pictures

QTZ40( 5008) FAQ

Q: What is 3 main mechanism of the tower crane?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: What is the function of the monitor?

A: Monitor, namely inspection system (like black box), which could store 10000 tower crane operation reports, and it is recommended to be installed in big cranes more than 16t.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients’ requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

- Q:I'm curious

- It's lifted in sections I believe. Once they're at their intended vertical height they then start to construct horizontally. Bit like big boys Mechano (not sure if I spelled that correctly).

- Q:What is a typical hourly wage, and what kind/how much training is required? Is there a special certificate that you have to get, sort of like a driver's or pilot's license? Does it vary much depending on what type of crane (track crane vs. tower crane)?

- Before you can operate a crane, you have to possess a trade certificate from a licensed agency. And before you got one, you have to undergo training and it depends on the extensiveness of the program of a licensed agency. the trade certificate is like a license, it has range of machines which you can operate with once license. Salary differs and it is based on hazards of work. A typical example is the crane operator in construction of Burj Tower. Being on the top of the building is not an easy job so the operator will likely receive salary more than a crane operator who is working in a typical high rise building.

- Q:What is the difference between Fujian White Crane Kung Fu and Wing Chun Kung Fu?

- White Crane Kung Fu

- Q:Examples of filling and acceptance forms for tower cranes and examples of filling in.

- 4 data filled in the requirements of the project, in addition to fill in the above sign, but also need to fill in the corresponding data. Data that needs to be filled in should be separated by "/" or "," and, if necessary, distinguished by text or graphic.

- Q:What were Henry's reasons for becoming a soldier? What about the war was so attractive to him?Why do you think it took Henry so long to begin contemplating his part in battle?How do Jim and Wilson respond to Henry's question? What does this tell you about them?Share your thoughts...

- The okorder /

- Q:From what I'm understanding in the first stanza, a women lost her lover to the war because he fell off his horse...Is that right?

- Yes, Stephen Crane talks about lost love and sacrifices in his poem. The basic casualty of war. A lover, a father and son are lost in his story and those that are left behind he tries to console. The poem is noted for the ironic use of war is kind. We all know that War is really not kind. The poem’s speaker, simultaneously sympathetic with the victims of war and cynical about the purposes of war, implicitly criticizes the image of the romantic hero, showing in graphic scenes the realities of battlefield death and the emotional torment it causes for those left behind.

- Q:any1??

- forces for cranes are dynamic , so u'll have repeated cycles of compression tension ( i assume it's a trussed crane). but generaly for a cantilever , the main forces are -ve Bending Moment +ve shear which changes the rft. bars position if dealing with R.Concrete for example

- Q:First Summary gets best answer...thanks!

- The City is covering itself by shifting the blame form a negligent city inspector to the crane company by charging its owner with Manslaughter Charges. This is typical of civil service personal who forget who they work for (We the People).

- Q:I'm a bit confused as to what happened to him. I guess I skimed a bit at a certain important part of the book. When Seneca Crane's name was written on the dummy during training, why did the people gasp at the name written in berry juice? What happened to him? PS. I am at the begining of Mockingjay. So no spoilers please. (:

- The same thing happened to me when i was reading the second book. I was so confused because i didn't understand why they were making such a big deal about this person that i didn't remember anything about. But Seneca Crane was the game maker in the first book. He was murdered by Snow and the Capital because Snow blamed Seneca for the fact that two people made it out of the Hunger Games. Hope this helps!

- Q:I started to make 1000 paper cranes to make a wish come true and before I start I have a few questions. How many times can you make 1000 cranes to make a wish come true? Do you have to string them? And how long do you have to make them?

- You only have to fold 1000 to make your wish come true. It doesn't matter how long you take on them, but they should look acceptable if you'd like to display them. All you really have to do is fold all 1000 cranes; you do not have to string them, but I think it looks very nice. You could also put them inside of a jar. :)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Cranes Model Self Raising Electric QTZ40( 5008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords