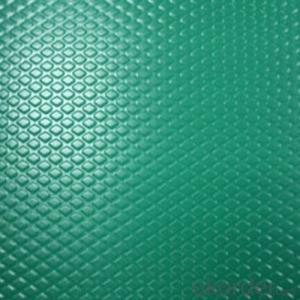

Anti-Slip Aluminium/Alu Alloy Embossed Checkered Tread Coated Aluminum Coil Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specifications of Anti-Slip Aluminium/Alu Alloy Embossed Checkered Tread Coated Aluminum Coil Sheet.

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Uage/Application of Anti-Slip Aluminium/Alu Alloy Embossed Checkered Tread Coated Aluminum Coil Sheet

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Anti-Slip Aluminium/Alu Alloy Embossed Checkered Tread Coated Aluminum Coil Sheet

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

4. Production Flow of Anti-Slip Aluminium/Alu Alloy Embossed Checkered Tread Coated Aluminum Coil Sheet

Melting-Rolling- Cutting- Annealing--Packing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines. Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC.

- Q:What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, in general, aluminum sheets are commonly available in standard sizes of 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are widely used in construction, manufacturing, and other industries due to their versatility and compatibility with standard equipment and processes. However, it's important to note that aluminum sheets can also be custom cut or ordered in different sizes to meet specific project requirements.

- Q:Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- This is the major topic of research for many commercial companies which prepare Oven and Grill cleaning products. The carbon itself is bound to the metal with denatured (carbonized) fat or oil molecules. These are generally effected only by very strong bases such as Sodium hydroxide (lye) which will react with aluminum and cause discoloration and chemical pitting. Mechanical removal using sharp blades or soft metal bristle brushes will work, but requires much labor. Steel wool is also used, but removes some of the metal from the surface of the pans. Special electrical devices have been used with success, but tend to slowly wear away the top layer of aluminum. Professional cooks ignore the problem by replacing aluminum with stainless steel pans. Home and do-it your-selfers tend to allow the buildup until everything sticks and then replace the pans. There has been a few who have seasoned their aluminum pans in a fashion similar to cast iron with mixed results. If this is for pizza pans for your restaurant, I suggest soaking the pans overnight in a strong solution of Dawn Dish-washing Liquid and then taking the pans to a steam car wash to remove the detergent.

- Q:Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- You should set this project aside. Ignore my advice? You're on track for a Darwin Award. You win!

- Q:According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- it particularly is authentic that many deodorants, quite those categorized anti-perspirants, incorporate aluminum chloride as an lively ingredient. Aluminum chloride does decrease sweat production via the sweat glands that are placed interior the floor and are quite ample under the hands. For some people who're heavy sweaters this drying consequence is amazingly significant. despite the fact that those deodorants decrease sweat production they do no longer block the sweat glands. we are no longer attentive to any at as quickly as risky outcomes on maximum persons from making use of a deodorant containing aluminum chloride. In our very close society at present, physique hygiene and prevention of physique smell are significant. in case you do no longer use a deodorant you are able to discover your persons the two complaining or keeping off you. while you're worried with reference to the drying consequence seem for a deodorant that would not incorporate aluminum chloride.

- Q:What are the different methods for bending aluminum sheets?

- Depending on the desired outcome and available equipment, there are various techniques for bending aluminum sheets. The following are some commonly used methods: 1. Manual Bending: For smaller projects, the aluminum sheet can be manually bent using a manual brake or bending tool. This can be achieved by hand with the assistance of clamps or a simple bending tool. 2. Press Brake: In industrial settings or for larger-scale projects, a press brake machine is utilized. It applies significant force through a punch and die set to create precise and consistent bends. 3. Roll Bending: To achieve long, continuous bends or curves, the aluminum sheet is passed through a series of rollers in the roll bending method. This technique is commonly employed in the production of cylindrical or conical shapes. 4. Rotary Bending: Thin aluminum sheets are effectively bent into curves using rotary bending. This method involves a rotating roller or wheel along the length of the sheet to create smooth and uniform bends. 5. Heat Bending: Thicker aluminum sheets or complex shapes often require heat bending. The sheet is heated to a specific temperature to enhance its malleability before being bent into the desired shape. It is crucial to consider factors such as aluminum thickness and alloy, desired bend angle and radius, and available equipment when choosing the appropriate bending method. Consulting professionals or referring to specific guidelines is recommended for optimal results.

- Q:Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

- Q:How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q:What are the different methods for finishing the edges of aluminum sheets?

- There are several methods for finishing the edges of aluminum sheets, depending on the desired outcome and application. One common method is edge trimming, which involves removing excess material from the edges of the sheet to achieve a smooth and straight edge. This can be done using various tools such as shears, saws, or routers. Another technique is edge deburring, which is used to remove any sharp or rough edges left after cutting. This is often done using sanding or grinding tools to smooth out the edges and create a more polished finish. Additionally, edge rolling is a method used to create rolled or rounded edges on aluminum sheets. This can be achieved through a rolling machine that applies pressure to the edges, bending them to the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to create custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that can enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option to consider. This process involves applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps to protect the edges from corrosion or other damage. Overall, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific requirements of the project.

- Q:How does my world Pocket Monster mod aluminum plate synthesize?

- The first ready aluminum ingot, hammer (wood and iron, iron mat Pocket Monster diamond).1, Pocket Monster put the anvil on the ground;2, holding the hands of ingot right-click on the anvil;3, hand hammer anvil point left to live, etc. the anvil 3 ring or anvil above the lump things deformation 3 times, right click on the anvil can take off the plate

- Q:What is the lifespan of the aluminum sheets?

- The lifespan of aluminum sheets can vary depending on several factors such as the quality of the aluminum, the environment in which they are used, and the level of maintenance they receive. However, aluminum sheets are known for their durability and longevity. On average, aluminum sheets can last anywhere from 20 to 30 years, but with proper care and maintenance, they can even exceed this lifespan. Regular cleaning, protection from harsh weather conditions, and avoiding exposure to corrosive substances can all contribute to extending the lifespan of aluminum sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Anti-Slip Aluminium/Alu Alloy Embossed Checkered Tread Coated Aluminum Coil Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords