Single Core PVC Insulated Cable 450 /750 V BVR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Core PVC Insulated Cable 450 /750 V H05V-U

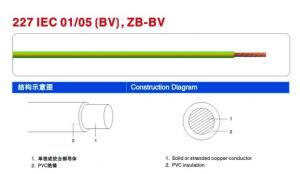

Production Introduction for Single Core PVC Insulated Cable 450 /750 V:

Voltage Rate: 300/500V, 450/750V

Range of Nominal cross section: 0.75 mm2 ~ 630 mm2

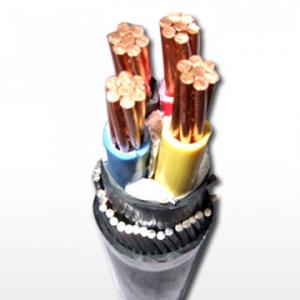

Conductor: Class 1/2 Plain annealed copper wires, solid or stranded

Constructions Insulation: PVC

Core color: Brown, Grey, Black, Blue, Green/Yellow or others on request

Max. Operating Temperature: 70℃, can be 90℃,105℃ as per requirement

Packing: 100 meter/roll or as per requirement

Application for Single Core PVC Insulated Cable 450 /750 V:

These cables are used for general purpose, as building wire for power, lighting and control wire to electrical appliances, suitable for use in conduit and for fixed, protected installation.

Production Standard for Single Core PVC Insulated Cable 450 /750 V:

IEC 60227, BS 6004, VDE0281, GB/T 5023, JB/T8734

The Feature for Single Core PVC Insulated Cable 450 /750 V:

The cable can be of flame retardance, fire resistance and other property

Packing photo for Single Core PVC Insulated Cable 450 /750 V:

FAQ For Single Core PVC Insulated Cable 450 /750 V:

Q1:What is the Production Capacity for your factory?

About 100 kilometer every day>

Q2: What is the Minimum Order Quantity For Single Core PVC Insulated Cable 450 /750 V?

MOQ: 10000 meters for small size, 5000 meters for middle size, 1000 meters for big size

Q3:What is the delivery time for these cables?

10~15 working days

Q4: What standards is the product complying with?

We can produce thousands of electric wires and power cables complying with different standards, such as: GB, JB , IEC, BS, AS/NZS, VDE, UL ETC.

- Q:Power cable casing buried what are the requirements

- 2 direct laying cable way, should meet the following requirements: 1 cable should be laid in the trenches, and should be along the length of the cable on the next, next to the side of the shop with a thickness of not less than 100mm soft soil or sand 2 along the length of the cable should cover the width of not less than 50mm on both sides of the cable protection board, protective board should adopt concrete 3 urban cable buried in the laying, it is appropriate in the protection board laying eye-catching signs 4 in the suburbs or open areas, along the cable path of the line spacing of 100m, corner or joint parts, should be erected obvious signs or signs 5 when the use of cable through the corrugated pipe laying in the trenches, should be along the full length of the bellows casting thickness of not less than 100mm of concrete, the width should not be less than 50mm outside the tube, the cable can not armor 3 buried in the non-frozen soil area, the cable embedding depth should meet the following requirements: 1 cable to the basement of the basement structure, not less than 03m 2 cable skin to the ground depth, not less than 07m; when located in the carriageway or farmland, should be properly deepened, and should not be less than 10m 4 buried in the permafrost area, should be buried below the permafrost layer, when not buried can be buried in the soil drainage of dry frozen soil or backfill, but also take other measures to prevent damage to the cable The 5 Directly laying the cable, is strictly prohibited in the underground pipe is just above or below The minimum distance between cable and cable, pipe, road, structure, etc shall be in accordance with Table 535 Table 535 Permissible minimum distance between cable and cable, pipe, road, structure, etc (m)

- Q:I've got 1/0 gauge wiring and if i run this along my rear deck quot;speaker wireswill this cause noise?im not talking about the RCA cables.

- i seriously doubt it.

- Q:Hey guysA 6mm power cable can hold up to 25A, but, if a product draws a maximum of 4A, in theory, can this 6mm be reduced? If so, by approx how much?Cheers, much appreciated!! :)

- Your wire has to be matched to the circuit breaker. If you have a 15 amp breaker you need #14 wire. Otherwise you could overload the wire and burn it out and the CB wouldn't blow.

- Q:I've looked on the internet, but it doesn't seem that the power cable for this printer is sold anywhere! Does anybody know if I'm able to buy it? And if so, where? I'm desperate. I don't want to buy a new printer. Even though this printer, actually, sucks. Let me know..........

- This Site Might Help You. RE: HP Deskjet F4280 - Power cable sold anywhere? I've looked on the internet, but it doesn't seem that the power cable for this printer is sold anywhere! Does anybody know if I'm able to buy it? And if so, where? I'm desperate. I don't want to buy a new printer. Even though this printer, actually, sucks. Let me know..........

- Q:its a rca home theater system and i need a power cable as my last one broke is there somewere were i can buy one

- There is a 95% chance it uses one of two standard power cord styles TVs these days come with, which is a 3 prong cord identical to what computers come with, or a polarized figure-8 cord, as some portable or bookshelf stereos come with You can get them anyplace that has A/V accessories.

- Q:I'm referring to the older models of both the PS2 and PS3, not the slim models.

- Controllers, yes, you just need a special adapter. Power cable, absolutely not, since the PS3 Fat uses a 3-prong power cable like what computers use and the PS2 uses a completely different kind with only 2.

- Q:I just recently purchased a PowerColor AMD Radeon HD 7850 graphics card (which didn't come with a power adapter cable) amp; needing to know what the power adapter cable looks like. If anyone could possibly send me a link with a picture, that would help out a lot.

- I think your power supply should already have one. If not not I suggest you look at PC Part Picker too find a good one that will work. Don't worry it will auto filter good ones for you. I can't help you if the graphics card doesn't have a female plug.

- Q:what cables do i need (besides a power cable) to start playing?

- 1). PS AV cable for standard TVs; 2). HDMI 1.3a for HDTVs; 3). RJ-45 cable if you plan a wired internet connection; 4). SB - miniB cable for controller; 5). Power cable (same as for PC).

- Q:I am trying to install a new Power Supply Dynex 520 Watt ATX and I cannot figure out what cable to connect to the hard drive. It was very small and I had a hard time connecting it. Do you have a clue?

- besides the actuality that maximum power aspects are interchangable, no longer all power aspects artwork on all structures. some issues to make valuable of while procuring a power furnish are one million. the recent furnish has the superb power pins could desire to connect on your motherboard and instruments. 2. the recent power furnish suits on your computing gadget case, the dissimilar severe end power aspects are somewhat extra desirable and don't sit down real in all circumstances, 3. the recent power furnish has the two sufficient Wattage and Amperage. a superb style of individuals make the blunders via getting getting a power furnish with too low amp score by way of fact it became into extra inexpensive. look at the two by way of fact they're the two important.

- Q:Whether high voltage cables can be built in belt corridors

- Electric workers in the wood when the wood bar, buried in the soil that part of the first use of fire char, and then brush into the ground after the bitumen

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Core PVC Insulated Cable 450 /750 V BVR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords