Silica Brick For Coke Oven CMAX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

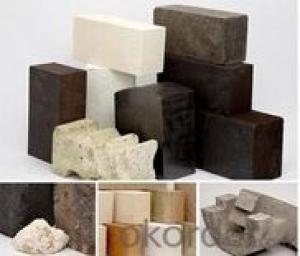

1.Silica brick for coke oven

2.SiO2:95%

3.ISO:9001:2008

4.27 years professional manufacturer

5.MOQ:1MT

Silica refractory brick for Coke oven

Features of Silica refractory brick for Coke oven:

1. high volume density of 2.35 g/cm3

2. high SiO2 content of 95%

3. low iron content of 0.8%

4. long working life of more than 20 years

Applications of Silica refractory brick for Coke oven:

The product is made of phosphorus quartz as main raw materials, and cristobalite as auxiliary material, it has high bulk density, strong thermal conductivity, high temperature stability, the long-term use of creep deformation, long service life (more than twenty years).

Physical and chemical index of Silica refractory brick for Coke oven

Index | Furnace bottom,furnace wall | Other parts |

SiO2 % ≥ | 95 | 95 |

0.2MPa Refractoriness under load °C ≥ | 1650 | 1650 |

Linear change on reheating 1450°C×2h % | 0~+2 | 0~+2 |

Apparent porosity % ≤ | 22 | 24 |

CCS MPa ≥ | 30 | 24 |

True desity g/cm3 ≤ | 2.34 | 2.35 |

Rate of thermal expansion (1000°C) % ≤ | 1.28 | 1.3 |

- Q:The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q:The chemical composition of silica brick and its physicochemical index?

- ????Al2O3 SiO2??????fe2o3??????cao???????r2o93~98?0.5~2.5?;;?0.3~2.5??0.2~2.7;??1~1.5;

- Q:Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q:Physical solid waste disposal

- Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products when firing, reduce cracks, improve the rate of finished products.

- Q:Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q:The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q:Such purpose and scope please give me detailed points thank you because I am learning stage

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

- Q:The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q:The introduction of silica brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q:What role does silica play in refractories?

- The natural mineral of silica is called quartz. In refractories, silica and siliceous refractory materials contain more silica. Silica is acidic at high temperature, and siliceous refractory can resist acid slag corrosion

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silica Brick For Coke Oven CMAX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords