China Aluminum Silica Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for China Aluminum Silica Refractory Brick

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Mullite |

| SiO2 Content (%): | 0 | Al2O3 Content (%): | >48 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | follow as customer's requirement | Brand Name: | |

| Size(mm): | 230x114x65/75 | Refractoriness(°C): | ≥1750-1790 | Bulk Density (g/cm3): | 2.2-2.3 |

| Apparent porosity(%): | ≤22-23 | Cold crushing strength (Mpa): | ≥39-54 | Refractoriness under load(0.2MPa) (°C): | ≥1420-1520 |

| Reheating Linear Change: | +0.1~ -0.4 |

Packaging & Delivery

| Packaging Details: | on wooden pullet covering by PE membrane or by customer's requirment |

| Delivery Detail: | within 30days after deposit |

Product Description

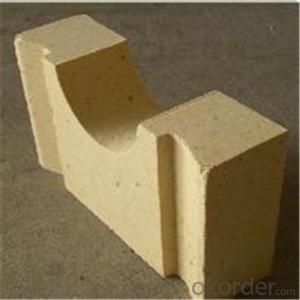

High Alumina Brick/Rrefractory Brick/Fire Brick

High alumina brick refers to fire brick containing Al2O3 more than 48%, which is made of high grade bauxite through high temperature calcinations. High alumina brick is a kind of neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion. It has characteristic of high refractoriness under load, which decide high alumina brick is a n ideal material for various kinds of industrial furnace. It is widely used in building lining of hot-blast stove, blast furnace, coke oven, rotary kilns of cement and so on. | |

Product name | China aluminum silica refractory brick |

Size and Specifications | 230x114x65mm 230x114x75mm

Special size brick is also available according to your drawings. |

Type | High Alumina Brick

|

Characteristics | 1 Excellent thermal stability 2 High refractoriness under load 3 Chemical stability and anti-corrision 4 Small high temperature creep rate 5 Excellent thermal shock resistance |

| Typical Use | 1 Building materials for blast furnace 2 Building materials for hot-blast stove 3 Building materials for coke oven 4 Building materials for steel making furnace 5 For ladle 6 For construction material in steel industry |

Operating Temperature | 1770°C |

Service | The size, density, chemical composition can be customized. |

Port | Qingdao Port |

Payment terms | L/C, T/T, D/A, D/P, Western Union, MoneyGram, Cash |

Delivery | Within 30 days after receiving deposit |

Packing | wooden pallet with shrinkage film, paper protect angle. |

Certificate | ISO 9001 |

Physial properties and chemiacal composition

Item | SK38 | SK37 | SK36 | SK35 |

Al2O3 % | ≥75 | ≥65 | ≥55 | ≥48 |

Fe2O3 % | ≤2 | ≤2 | ≤2 | ≤2 |

Refractoriness °C | ≥1790 | ≥1770 | ≥1750 | ≥1420 |

Apparent porosity % | ≤23 | ≤23 | ≤22 | ≤22 |

Cold crushing strength Mpa | ≥53.9 | ≥49.0 | ≥44.1 | ≥39.2 |

Refractoriness under load(0.2MPa) °C | ≥1520 | ≥1500 | ≥1470 | ≥1420 |

Reheating Linear Change % | +0.1(1500°C, 2h) | -- | ||

-0.4(1400°C, 2h) | -- | |||

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Warmly welcome friends and customers all over the world to pay a visit to factory!Hopefully both of us can establish a long-term cooperation!

Packaging & Shipping

1.Packing by Plastic film and pallets or wooden box and others as requested.

2.Shipping by 20Ft container.

3.For more details of our products and others.Please kindly contact us.

FAQ

3.Common question:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:What is the silica refractory products?

- Refractory brick with silica content greater than 90%.

- Q:How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q:Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q:Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q:The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q:The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q:What is the main material of silica brickIt's common, the kind we see so often!

- More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance.

- Q:The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q:The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q:The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China Aluminum Silica Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords