Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

Description of Rubber Conveyor Belt

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildew-proof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

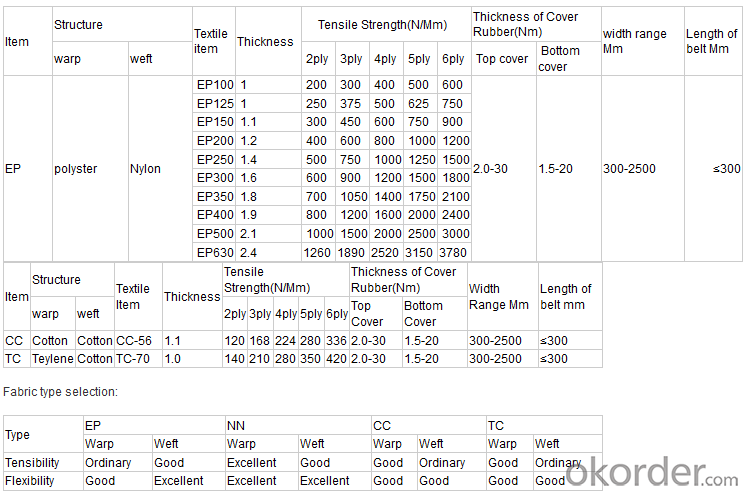

Specification of Rubber Conveyor Belt

1) Fabric: Cotton, Nylon, Polyester

2) Width: 200mm-1800mm

3) Thickness: 4mm-20mm

4) T/S: 8Mpa-24Mpa

USAGE: mining, metallurgical industry and architectural industry, ports etc.

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q:Properties and specific uses of various rubbers

- Synthetic rubber is made by synthetic methods, and different kinds of rubber can be synthesized with different raw materials (monomers). Such as, butadiene rubber, chloroprene rubber, styrene butadiene rubber and so on. The yield of synthetic rubber has greatly exceeded that of natural rubber, of which the largest yield is styrene butadiene rubber.

- Q:Is mixed silicone rubber dangerous?

- With excellent thermal stability, high and low temperature resistance, can -60 to +250 DEG C under the condition of long-term work, ozone resistance, weatherability and good electrical properties, corona resistance, electric arc, electric spark is extremely strong, with chemical stability, weathering resistance, radiation resistance, physical inertia and good air permeability.

- Q:Rubber products on tiles, why tiles yellow?

- Rubber products generally contain operating oil, the role is to make rubber easier to process and soft. But the oil runs easily to the surface of the rubber, so it makes the tiles yellow.

- Q:What material is the rubber used in the tires?

- The tyre is known, usually made of rubber materials, a solid tire and pneumatic tire parts, pneumatic tyre and tubeless tire composed by.

- Q:Can PVC blend with rubber?

- PVC can be well compatible with NBR and difficult to use with other glue.

- Q:Why does rubber burn black smoke?

- Rubber is filled with black carbon, which is used to dye, but to increase hardness, burning black smoke.

- Q:What are the causes of the rubber products breach?

- First: the use of rubber joints in the process of linking the length is not enough to force beyond the length of the link, the expansion of the scope of contraction may also splitSecond: rubber joints, the strength of the link is relatively low, then if the adhesive method is not accurate, the strength of the joint will be lower, there may be crackingThird: rubber joints after installation, in other places free here beyond the extension range of pipe strap, there may be cracking.Fourth: rubber joints in the outdoor adverse weather, explosion, sun, etc., lower than the use of temperature may also crack.Fifth: in the process of production of vulcanized rubber joint used in rubber function is not good or has been since sulfur failure, excessive grinding, wire rope and other parts of the rust, the joint strength will be greatly reduced, when in use, will likely easily disconnect joint phenomenon

- Q:What is the difference between silicone rubber and silicone rubber?

- The word language belongs to the chaos of the silica gel in above, there is no accurate way, and the types of silica can be divided into organic and inorganic silica gel, we in the life of common orthopedic medical cosmetic is divided into inorganic silica gel is a kind of amorphous chemicals into different pore structures which belongs to a liquid form of silica gel. It can be used in human tissue because it is non-toxic, no stimulation, no response to any material, has good stability, in addition to the medical industry in other industries can effectively use the strong adsorptive force so as beer silica gel, silica gel desiccant, viscose and so on

- Q:What are the hazards of waste rubber and how can they be used for regeneration?

- Every year, millions of tons of waste rubber are produced in the world, and the quantity is so huge. How to deal with them effectively has become a common concern of the whole society.

- Q:Does anyone know how to deal with the frosting of rubber and how to prevent it?

- To reduce blooming, mainly by adjusting the formula to achieve, such as reducing the amount of antioxidant in summer, storage time is short before vulcanization, if you can consider the use of paraffin wax, microcrystalline wax, if sulfur spray frost can consider changing into insoluble sulfur. Because I don't know your recipe, I adjust it according to the actual situation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords