Rubber Chemcials Rubber Antioxidant PAN (A)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PAN (A)

Chemical Name:N-Phenyl-α-naphthylamine

Molecular Formula:C16H13N

Molecular Weight: 219.28

CAS NO.:90-30-2

Executive standard:GB/T 8827-2006

Specification:

| Index |

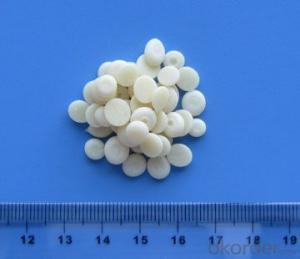

Appearance: | Yellow or purple flake |

solidifying Point.℃ ≥ | 53.0 |

Free amine (phenyl amine)% ≤ | 0.20 |

Volatile,%≤ | 0.3 |

Ash,% ≤ | 0.10 |

Properties: Yellow or purple flake. melting point 62℃,boiling point 335℃,flash point 188℃, relative density 1.16-1.17, Soluble in acetone, benzene, ethanol, carbon tetrachloride, chloroform, soluble in gasoline, insoluble in water. Exposure to sunlight and air in the Gradient purple, flammable.

Applications: This product is commonly used in tire, hose, tape, rubber, adhesive tape products, as well as a variety of other industrial rubber products dark antioxidant, may also be used as stabilizer in the styrene-butadiene rubber.

Packing:Polypropylene knitted bags lined with polyethylene bags.Net weight 25kg per bag.

Properties: The product should be stored in the dry and cooling place with good ventilation. The product should be avoid hot sunshine.

- Q:Chemical reaction plus catalyst on the △ H no effect

- Since the addition of the catalyst only accelerates the reaction process and does not have an effect on the reaction product and the reactants

- Q:Explain how catalysts help to reduce costs in industrial processes !?Thanks

- they reduce the activation energy of a specific chemical reaction, which in turn reduces the temperature at which a reaction will occur at any significant rate (and therefore fuel costs) while generally making the reaction occur faster. In general, if you can catalyze a reaction, you can get away with using less robust equipment because you don't need as much energy.

- Q:What is a catalyst in a chemical reaction?

- I didn't actually need to know what a catalyst was for my chemistry exam just what it does. A catalyst is something that speeds up a chemical reaction.

- Q:What is the analytical principle of chemical adsorbents? How about the number of active catalyst centers tested?

- What do you mean by the chemical adsorber? BET is the use of the surface of the uneven force field, but the inert gas at low temperature in the surface adsorption. TPD, TPR is the number of active centers that can be measured by the technique of desorption and reduction between specific gases and catalysts as the temperature increases. If the active site is a reduced position, H2-TPR can be used. If the active site is acidic, NH3-TPD can be used, but also the method of alkali titration.

- Q:Why would the Eact decrease if a catalyst is added?

- A catalyst by its very nature increases the rate of reaction by binding to a reactant, hence changing its shape and reactivity with other reactants. However, the catalyst is neither consumed nor will it change the chemical shape of the products.

- Q:When you write a chemical equation, how do you want to add "catalyst" and "?" When you do not have to write?

- This is the need for your memory, write a few times, will naturally cooked

- Q:Why are catalysts so effective in small amounts?

- Catalysts don't get used up in reactions. Because of this, a single catalyst molecule can function again and again. Some catalysts are better than others for a given reaction. More effective catalysts reduce the time taken for 1/ the rate of travel of the molecule to the active site, 2/ the time the reaction takes, or 3/ the time it takes for products to diffuse away, or 4/ a combination of the above. The more effective a catalyst is in these factors, the less is needed to make it equally effective.

- Q:and what type of macromolecule are they made of? thanks!

- by definition a catalyst is a substance that alters the cost of, or makes accessible, a chemical or biochemical reaction yet maintains to be unchanged on the tip of the reaction. Enzymes are the only organic biochemical catalysts. Ribozymes are a particular sort of enzymes. certainly, the definition of enzyme rates: organic and organic catalyst produced in cells, and able to dashing up the chemical reactions mandatory for all times. they're great, complicated proteins, frequently soluble, and are noticeably specific, each and every chemical reaction requiring its very own specific enzyme. The enzyme's specificity arises from its energetic website, a community with a shape such as portion of the molecule with which it reacts (the substrate). the form of the enzyme the place the chemical binds in straightforward terms facilitates the binding of that distinctive chemical, such as a particular key in straightforward terms working a particular lock (the lock and key hypothesis). The enzyme and the substrate slot jointly forming an enzyme–substrate complicated that facilitates the reaction to ensue, and then the enzyme falls away unaltered. In prepare maximum catalysts are used to velocity up reactions. There are different non-organic and organic catalysts. maximum of that are utilized in industry and are commonly transition metals or their compounds.

- Q:Like biological and industrial reations. Thanks.

- Reactions that have high Activation Energy need catalysts to speed up reactions. These reactions aren't spontaneous since the reactants do not have enough energy to overcome the activation energy barrier. Catalysts are compounds that speed up reactions by providing an alternative pathway for the reaction. It is a common misconception that catalysts lower the activation energy. It doesn't actually lower the activation energy, instead it provides an alternative pathway with lower activation energy. For example, breakdown of hydrogen peroxide happens in nature but, relatively slowly. When you add a little bit of manganese dioxide, the breakdown happens a lot faster. Another example is, breakdown of glucose in the body. It is facilitated by an enzyme called amylase (or carbohydrase). An industrial example is the use of vanadium pentoxide (V2O5) in the Contact process, where SO2 is converted to SO3 in the presence of V2O5. Hope that helps!

- Q:Hydrogen and nitrogen in the high temperature and pressure and catalyst conditions for the synthesis of ammonia chemical equation

- 3H2 + N2 catalyst iron ---> 2NH3 conditions high temperature and high pressure

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber Chemcials Rubber Antioxidant PAN (A)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords