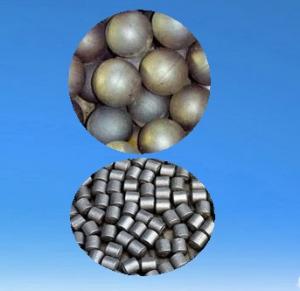

Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral Processing and Cement

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features and Advantages of Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral

Processing and Cement:

1) High hardness: It has high hardness: surface hardness can reach 55-67 HRC, volume hardness 56-64 HRC

2) High Impact toughness: impact toughness is more than 15 J / cm2.

3) Low Broken rate: peel fragmentation resistance property of over 20000 times. The actual breakage rate is less than 1% and close to 0.

4) Size: Our products range from 20mm to 150mm, 1 inch to 6 inch, and we can also offer all size of products according to clients’ demand.

Chemical Elements of Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral

Processing and Cement:

Type | Name | C | Mn | Si | Cr | S | P |

CMAX-F01 | 20MN | 0.12-0.22 | 1.00-1.60 | 0.60-0.80 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F02 | 45# | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F03 | 50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F04 | 60MN | 0.57-.0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F05 | 65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F06 | B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.035 |

Specification and Hardness of Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral

Processing and Cement:

Type | Name | Impact Test AK.J/cm2 | Endurance Test Times(5m) | Dia 25mm-60mm | Dia 70mm-100mm | ||

Surface | Core | Surface | Core | ||||

CMAX-F01 | 20MN | ≥12 | ≥10000 | ≥42 | ≥48 | ≥40 | ≥45 |

CMAX-F02 | 45# | ≥12 | ≥10000 | ≥52 | ≥48 | ≥53 | ≥46 |

CMAX-F03 | 50MN | ≥12 | ≥10000 | ≥56 | ≥50 | ≥55 | ≥50 |

CMAX-F04 | 60MN | ≥13 | ≥12000 | ≥58 | ≥52 | ≥58 | ≥50 |

CMAX-F05 | 65MN | ≥15 | ≥12000 | ≥62 | ≥54 | ≥58 | ≥52 |

CMAX-F06 | B2 | ≥15 | ≥12000 | ≥62 | ≥55 | ≥58 | ≥52 |

- Q:Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q:Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q:How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q:For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to the grade of the parts, according to the relevant standards, the regular drawings will be noted in the technical requirements of the parts.

- Q:How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- I am doing this for sale, if the price is mainly based on the product structure, the difficulty of pricing. At present, if it is more formal and material guarantee manufacturers generally in 48-53 yuan /Kg (of course, products have a certain weight, such as greater than 100g), our company's current price of about 53 yuan /Kg or so. .

- Q:We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q:Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q:I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q:the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q:Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral Processing and Cement

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords