Best-quality High Chrome Casting Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

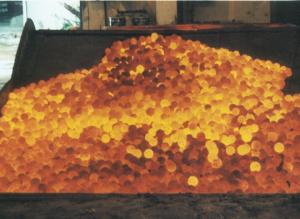

General Information of Best-quality High Chrome Casting Bars

CMAX products have excellent surface finish, high load carrying capacity, high intensity, high hardness, high wear ability, high temperature resistance, impact resistance, low damage percentage and so many other features. CMAX products can help corporations to promote production, reduce production cost, reduce labor intensity of the workers.

Specifications of Best-quality High Chrome Casting Bars

1)High hardness&low breakage

2)Good wear resistance

3)Reasonnable price

Application of Best-quality High Chrome Casting Bars

CMAX High Chrome Casting Bars are widely used in powder preparation and super finishing for the devices of cement, building materials, metallurgy, thermal power plant, ceramics, refractories and the other industries.

Our company has success in the products due to their cost-effectiveness, excellent strength and resistant properties. We also have experience in casting bars application and would like to assist you in product selection, system design, and installation techniques.

- Q:As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q:What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q:What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q:How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q:In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q:How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q:Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q:The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q:When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q:the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Aluminum alloy die-casting parts or casting box and other parts of the threaded hole, in the case of processing conditions, it is best to use wire tapping or machine tool processing! Direct casting is not advocated.

1. Manufacturer Overview |

|

|---|---|

| Location | Anhui, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 million |

| Main Markets | Mid East; Eastern Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 50% |

| No.of Employees in Trade Department | 31-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best-quality High Chrome Casting Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords